A Look at Micro Pelletizing

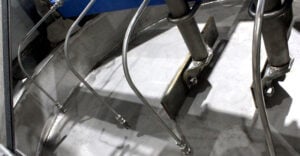

What is Micro Pelletizing? Micro pelletizing is the process of agglomerating material fines into small pellets. Unlike traditional pelletizing, where slightly larger pellets are produced, micro pelletizing produces pellets around 20-60 mesh. Micro pelletizing can be carried out either in a stand-alone pin mixer (this …