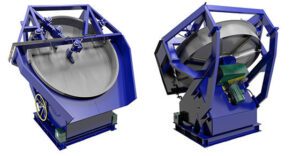

Photo of the Week: Moisture Analyzer

This week’s photo highlights a moisture analyzer from the FEECO Innovation Center. FEECO’s process experts use the moisture analyzer prior to, during, and after processing materials, to record the amount of moisture in each sample. With most materials, reaching a specific moisture range, or even …