One of the most important design decisions in configuring an industrial bucket elevator is whether to use a belt or chain bucket elevator.

While both configurations are capable of transporting material vertically and continuously, they do so with very different characteristics. This article explores the key differences between belt and chain bucket elevators.

Belt Bucket Elevators

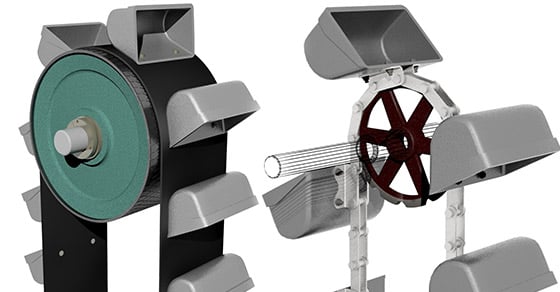

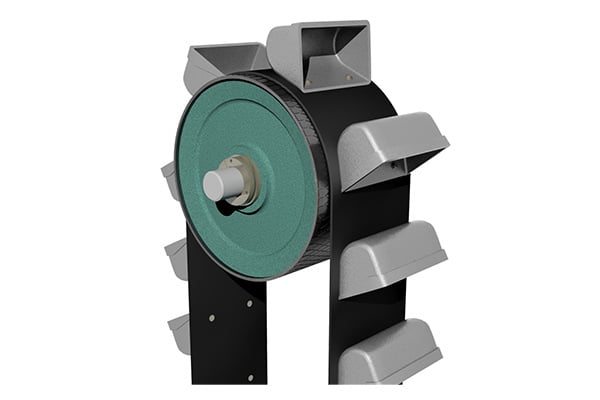

Belt bucket elevators offer a cost-effective, reliable solution in a number of settings. In this configuration, buckets are mounted onto a heavy-duty belt with bolts.

Belt-style bucket elevator with centrifugal buckets.

Key Advantages:

- Low cost

- Low noise

- Resistant to corrosion, especially when paired with plastic buckets and lagged or stainless pulleys (chemical-resistant belting is also available)

Disadvantages:

- Less durable

- Not suitable with hot materials or large particles (as they could become lodged between buckets and belt)

- Can be damaged by shock loading

- Temperature limitations, unless utilizing high-temp belting

- Not suitable for very tall discharge heights

Belt Elevator Applications

Belt bucket elevators are ideal in settings where light-to-moderate duty handling is required and material temperature is not a concern.

Common use cases for belt bucket elevators include:

- Cement plants (raw material feed)

- Sand plants

- Fertilizer handling

Inspection Requirements of Belt Elevators

Maintenance requirements are generally comparable between belt and chain elevators, but inspection items differ.

Belt elevators:

- Require regular tension checks and belt tracking/alignment.

- May experience slippage or stretching over time.

- Are susceptible to damage from heat, chemicals, or sharp material edges if not properly designed (and should be monitored as such).

- Require careful inspection and monitoring of splice points, belt, and bucket connections to belt.

Chain Bucket Elevator

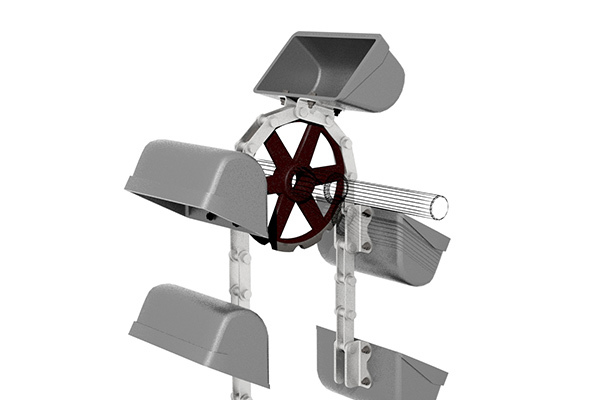

Chain bucket elevators are extremely heavy-duty, offering a robust handling solution for especially demanding settings. In this configuration, buckets are mounted onto a single or double chain via steel link attachments.

Chain bucket elevator with buckets fastened by chain attachments.

Key Advantages:

- Extremely durable

- Capable of handling hot materials and large particle sizes

Disadvantages:

- Higher upfront cost

- Increased operating noise

Chain Elevator Applications

Chain bucket elevators are suited for the harshest industrial conditions, especially where:

- Material is hot, abrasive, or corrosive – Chain is more robust and capable of handling materials with challenging characteristics, making it ideal for materials like clinker, coal, potash, or catalysts.

- Shock loading is possible – In processes where sudden surges in material or larger lump sizes may occur, chains provide better durability and resistance to stretching or failure.

- Vertical lift height is extreme – Chain designs are often better suited to very tall elevators, where tension and wear on a belt would become impractical.

- Continuous operation is critical – In demanding applications where downtime is especially costly, chain elevators generally offer a longer service life and more rugged performance under duress, when properly maintained.

Common use cases for chain elevators include:

- Clinker cooling systems

- Potash conveying in mining operations

- Catalyst handling

- Ore or aggregate transport

Inspection Requirements of Chain Bucket Elevators

As with belt elevators, chain elevators also require regular monitoring, though not quite as much. With a chain elevator, typically only the chain and sprockets require routine monitoring for signs of wear.

Key Selection Criteria

Understanding the differences between belt and chain elevators helps to ensure that the equipment integrates efficiently into the broader process and facility design. While there are many differences between the two types, the deciding factors typically come down to:

Cost

Winner: Belt Elevators

Belt elevators are less costly. However, level of duty should not be sacrificed in favor of a lower capital cost, as belt elevators could present a greater risk of failure in settings better suited to a chain elevator.

Level of Duty (Durability)

Winner: Chain Elevators

Belt elevators simply cannot match the durability of chain elevators; chain elevators experience less wear and tend to last longer, particularly in tough conditions.

Temperature

Winner: Chain Elevators

While high-temperature belting offers effective protection against heated materials, chain elevators still stand up better to hot materials in general. If temperatures are below 300°F, however, a belt elevator can be a suitable option.

Personnel

While not necessarily a deciding factor, another potential consideration is what the operation and maintenance personnel are familiar with. In cases where the elevator(s) will be replacing an existing unit or added to a facility with existing units, some plant managers may choose to stick with the type of elevator their personnel know best. Albeit minimal, this helps to avoid any learning curves associated with bucket elevator operation and maintenance.

Summary of Key Differences: Belt vs. Chain

| Feature | Belt Bucket Elevators | Chain Bucket Elevators |

| Material of Construction | Fabric-reinforced belt | Steel chains |

| Service Environment | Best for clean, dry, cool materials | Ideal for hot or abrasive materials |

| Bucket Attachment | Buckets bolted to belt | Buckets fastened via steel link attachments |

| Wear Characteristics | Good up to moderate wear settings | Designed to withstand high-wear settings |

| Shock Load Resistance | Less tolerant to shock loads | Better at absorbing shock and overload |

| Maintenance | Requires belt tensioning and alignment | Requires chain tensioning and sprocket inspection |

| Cost | Lower initial cost | Higher initial cost |

| Operating Noise | Low | Higher due to chain riding over pulleys |

Final Thoughts

Both belt and chain bucket elevators have their place in industrial applications, and selecting the right configuration can have an impact on process efficiency, equipment longevity, and cost. For light- to moderate-duty applications in controlled environments, belt elevators offer a cost-effective option, but are limited by material characteristics and belt limitations. For demanding, high-wear environments where throughput is especially high, chain elevators provide the robustness and durability required to ensure long-term reliability.

Ultimately, working with an experienced bucket elevator manufacturer can help ensure the right selection based on a detailed understanding of the material and process conditions.

Need help selecting the right elevator for your application? Contact us today!