Managing spare parts is critical to keeping industrial equipment running and avoiding costly downtime, but maintenance managers and reliability engineers often face a common dilemma: choose the quick, low-cost aftermarket replacement, or invest in genuine original equipment manufacturer (OEM) parts.

While aftermarket options can provide short-term savings or fast availability, OEM parts are designed for precise fit, reliability, and long-term performance. For those managing high-value capital equipment such as rotary dryers, kilns, and bucket elevators, understanding the trade-offs is essential to making the right decision.

When is it important to select OEM parts?

The choice between OEM and aftermarket parts is dependent on each plant’s appetite for risk. Plant managers and maintenance personnel must balance short-term needs with long-term risks in determining what is right for their specific scenario. That said, there are several settings in which relying on OEM parts may not be optional, but necessary:

When Ensuring Proper Fit & Compatibility

Genuine OEM parts are engineered to the exact specifications of the equipment, ensuring seamless fit and proper alignment. This precision eliminates the need for modifications to achieve fit and prevents issues such as interference, misalignment, and early wear.

Aftermarket substitutes, marketed as “universal fit,” often lack this accuracy, creating risks of improper installation and premature failure (these issues are also common when third-party fabricators attempt to duplicate OEM parts).

When Looking to Maximize Performance & Longevity

Because OEM parts are built for the original design and duty, they help maintain throughput, efficiency, and reliability over the long term. Manufactured from heavier materials and to higher quality standards, OEM parts tend to extend service life and reduce unplanned downtime. In contrast, aftermarket parts often trade durability for lower cost, resulting in more frequent replacements and higher long-term costs.

OEMs can also offer recommendations when original specifications are not available, or when different specifications might be a better fit based on the equipment’s existing condition.

In the case of drum tires and trunnions, for example, properly matching surface hardness, which work hardens over time, is critical to minimizing wear. The outside diameter (O.D.) surface hardness of the opposing component (tire or trunnion wheel) must be measured with a hardness tester, allowing an appropriate hardness to be calculated for the replacement component that promotes the best-case lifespan. Since trunnion wheels and tires experience wear at each point of contact with a drum differently, this must be carried out for each replacement.

Estimating hardness is not recommended, because if the hardness is not an appropriate match for the opposing component (whether too soft or too hard), premature wear will occur.

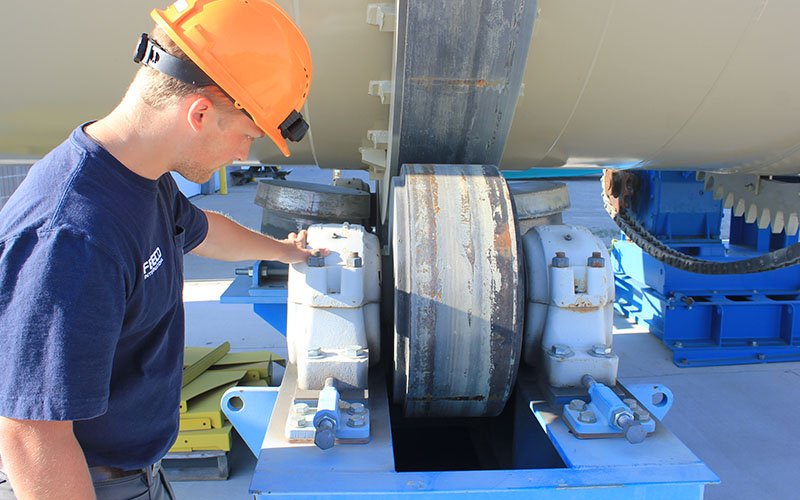

Replacement trunnion wheels

It’s also important to recognize that some components cannot be replaced independently without the right expertise. For instance, an aftermarket supplier may provide a standalone trunnion wheel, plant maintenance personnel must then have the tools and skills to sweat-fit the wheel to the shaft and properly install the bearings—requirements that often don’t become apparent until the new part arrives onsite. By contrast, an OEM considers the plant’s resources upfront and recommends the replacement approach best suited to the situation.

In Protecting Your Investment

Genuine parts help to protect capital equipment investments by eliminating the risks associated with lower-quality parts.

In settings where a worn or failed component has the potential to impact other components, aftermarket substitutes are especially risky. As with the trunnion example above, a poorly matched trunnion wheel could ultimately result in damage to both tire and trunnion, requiring both components to be replaced.

When Trying to Reduce Safety & Liability Risks

OEM parts are designed to meet the original safety requirements and specifications required by the equipment, ultimately reducing the risk of operator hazards, as well as unplanned downtime and catastrophic failures.

For example, OEM trunnion bearings are engineered with the appropriate safety factors to deliver reliable performance over a defined service life for the intended application. An aftermarket bearing, however, may not meet the same safety margin or life cycle—something the customer often has no way of knowing—leaving them with an unseen liability.

The same holds true for guarding. While a fabricator may be able to supply a guard that appears comparable, it may not adequately protect against pinch points or other hazards to the standard required by OSHA or MSHA. When this occurs, what appears to be a safeguard can actually introduce additional risk.

In Maintaining Warranty & Support

One of the most essential reasons for choosing OEM parts is to preserve all warranties and avoid excess rework.

The use of certain aftermarket parts may void equipment warranties in some cases, or, the OEM may exclude certain aspects or parts of the warranty due to the use of aftermarket replacements.

Warranties on replacement parts may also be problematic. As an example, even if manufacturers are supplied with the complete specification for girth and pinion gears, if the girth gear is manufactured by one company and the pinion gear by another, the tooth profile will differ, which could result in premature wear. A warranty claim in this case would likely not be covered by either manufacturer since neither produced both gears. The same holds true when replacing the chain and sprocket components in a chain-drive assembly.

Moreover, aftermarket parts typically do not come with the same level of support as OEM parts. As mentioned, aftermarket parts will often require significant modification to achieve the right fit, only to fail prematurely or never truly fit, requiring the OEM to come in and resolve the resulting issues, further adding to costs.

Further, the selection of the appropriate aftermarket part may be unclear, resulting in a lengthy and troublesome trial-and-error approach to replacement. In contrast, OEMs often provide a list of spare parts as part of an equipment purchase, and if confusion arises, can quickly identify the most suitable replacement.

Ordering from the OEM also means that if in-house expertise is not available to replace the part, the OEM can provide a service technician to perform the work.

Newly installed girth and pinion gears

When is it Okay to Choose Aftermarket Parts?

Despite their associated risks, there are settings in which the use of aftermarket parts may be justified.

When Fast Availability is Critical

Depending on the type of component, OEM parts may come with a longer lead time, whereas aftermarket parts can typically be pulled from a shelf and shipped immediately.

Thus, when unplanned downtime due to a failed component is accruing significant costs, the risks associated with aftermarket parts are often outweighed by getting the production line up and running as quickly as possible.

For this reason, many maintenance managers will opt for an aftermarket part to get their operation running in the interim while they wait on an OEM part to arrive.

For instance, aftermarket pneumatic cylinders are widely available. If a review of dimensions and specifications can confirm that the aftermarket replacement is identical in form, fit, and function, there is little-to-no risk in utilizing an aftermarket substitute to get the operation running while waiting for a genuine replacement.

This approach provides a good compromise to balancing immediate needs with long-term reliability.

When Risk is Low

Because many aftermarket parts are designed as one-size-fits-all solutions that can be produced efficiently by multiple manufacturers, they are often less expensive than OEM parts. As such, when the associated risks of an aftermarket substitute are low, the lower cost may be worth the trade-off.

For example, non-critical wear liners, fasteners, and the like can often be sourced from an aftermarket supplier with little risk, though it’s important to keep in mind that OEM support may offer a time savings if compatibility issues arise.

OEM Parts vs. Aftermarket Parts: Pros & Cons Summary

OEM Parts: Pros

- Guaranteed fit and compatibility

- Maintains original equipment performance

- Built to higher quality standards and longer service life

- Backed by OEM support and expertise

- Protects warranties and reduces liability risks

- Listed in spare parts list

OEM Parts: Cons

- Longer lead times in some cases

- Typically higher upfront cost

Aftermarket Parts: Pros

- Often available immediately for urgent needs

- Lower upfront cost

Aftermarket Parts: Cons

- May require modification to fit properly

- Quality and performance less consistent

- Can cause premature wear or failure

- Not backed by OEM warranty or support

- Potential to void existing equipment warranty

- Not provided in a spare parts list (may require trial and error or additional research)

Working With a Qualified Parts Supplier

One of the best ways to make parts management easier, whether building a spare parts inventory or sourcing a failed component quickly, is to have a relationship with a qualified parts supplier.

The FEECO Parts Team can work with you to assess your needs and determine the best approach, whether the solution is a FEECO OEM part or an aftermarket substitute.

FEECO recently assisted a sugar producer by measuring the customer’s rotary dryer and designing a floating tire mounting kit to correct their existing cold gap. Keepers were custom designed with chamfers to prevent interference with a non-traditional feature on the drum. The result was a successfully remounted tire with minimal creep.

Beyond advising on parts and conducting retrofits and other service work, FEECO can also help you to build a spare parts inventory, providing inspections and recommending wear-critical parts to keep in stock versus those that can be ordered as needed.

A FEECO Customer Service Engineer inspects a trunnion base

Conclusion

The choice between OEM and aftermarket parts ultimately comes down to balancing risk, reliability, and cost. While aftermarket substitutes may provide a quick or low-cost option in certain situations, OEM parts remain the clear choice for maintaining long-term equipment performance and protecting investments. By working with a trusted parts supplier, maintenance managers and reliability engineers gain access not only to genuine OEM components, but also to the expertise and support needed to make confident decisions that keep operations running smoothly. To learn more about the FEECO Parts Team and our offerings, contact us today!