SELF-SUPPORTING, SUPER-CAPACITY BUCKET ELEVATORS

A self-supporting elevator eliminates the need for external structural steel to support vertical loads, making it ideal for outdoor applications or situations where existing infrastructure does not allow for the necessary steel supports.

These elevators come in various configurations and sizes. And while a range of self-supporting bucket elevators are available on the market, few can offer self-supporting bucket elevators for super-capacity applications. These elevators fill a critical gap in the market for those with existing elevators no longer served by the original manufacturer and reaching their end of life.

In addition to smaller sizes, FEECO’s self-supporting, super-capacity bucket elevators can accommodate a throughput of up to 800 TPH, making them ideal for use at potash facilities and other sites requiring extreme throughput.

The Self-supporting design

Non-self-supporting elevators rely on external structural steel to support the majority of the equipment and material load. In these elevators, bearing pads on the head section are attached to surrounding structural steel, which supports the head section, leaving only the intermediate and boot casings for the foundation to support. Because the head casing is rigidly mounted to the structural steel, an expansion joint is placed beneath it to allow for the thermal expansion of the intermediate casings.

In contrast, a self-supporting elevator is entirely self-supporting, with the casing and foundation bearing the full load of the unit. While lateral bracing is still required to handle external horizontal forces like wind or seismic activity, all vertical loads are supported by the casing and foundation.

In a self-supporting elevator, the head frame, which is affixed to the bearings, transfers the unit’s weight to gusset plates, which then transfer the load to the casing (the torque arm is also mounted onto the head frame). Due to the significant load—up to 40,000 pounds of chain pull, plus the weight of the casings and drive components—self-supporting elevators require a much more robust construction compared to non-self-supporting designs. Each elevator is structurally analyzed by a licensed Professional Engineer to ensure the casing is designed to withstand these extreme loads.

benefits

- Completely self-supporting (no need for external steel supports)

- Less costly than a traditional elevator paired with the necessary steel supports

FEATURES

- Specially designed head frame

- Gusset plates (for distributing load to casing)

- Heavy-duty angle iron for vertical supports and crimp stiffeners

- Gravity take-up

- Removable top covers

- Access doors for easy maintenance

- Horizontally and vertically heavy-reinforced, jig welded head, boot, and intermediate sections

- Adjustable throat plate at discharge

- Inspection doors on both sides of discharge

- Service platforms and access ladders available

- Heavy-duty, robust construction

- Custom design

- Various bucket designs available

- Robust bearings, pulleys, and drive options

- Optional variable frequency drive (VFD); our elevators can be connected to plant-wide VFD’s or we can supply a remote/panel-mounted VFD, which is beneficial for maintenance and “creep control.”

CONFIGURATIONS

FEECO can supply self-supporting bucket elevators in either a centrifugal or continuous configuration. For both options, the elevator can be either the belt or chain type.

CENTRIFUGAL

Centrifugal bucket elevators are ideal for moving large quantities of material quickly. In this design, buckets serve as the loading mechanism, scooping material from the boot or inlet section rather than being directly loaded. Because of this, durable buckets are recommended for centrifugal bucket elevators.

At the head pulley, centrifugal force “throws” the material from the buckets into the discharge chute. The buckets are spaced further apart to prevent discharge interference from the preceding bucket, ensuring maximum fill at the boot end while operating at higher speeds. This design optimizes bucket fill and minimizes interference between buckets.

Centrifugal elevators are well-suited for handling free-flowing bulk solids like sand, gravel, wood chips, and other materials where fragility is not a concern.

CONTINUOUS

Continuous bucket elevators are designed for applications requiring gentle handling, making them ideal for transporting friable or fragile materials where minimizing product degradation or damage is crucial. They are also well-suited for sluggish or abrasive solids and light, free-flowing materials where aeration must be avoided.

In this design, material is fed into the buckets from an inlet chute. The buckets are closely spaced on the belt or chain to allow for gentle, continuous discharge. As the material flows over the backside of the preceding bucket, the extended sides of the bucket form a chute, guiding the material into the discharge spout. This direct loading, combined with the slow operating speed, prevents the “throwing” action found in centrifugal elevators, making continuous bucket elevators ideal for handling fragile solids.

BELT Bucket Elevators

Belt elevators offer a cost-effective approach for lighter-duty jobs. Buckets are mounted onto a belt made of various compounds depending on the application.

The belt design is ideal in settings where noise is a concern, as this approach offers quiet operation.

CHAIN bucket elevators

Chain elevators provide a higher-capacity, more durable option. They are best for jobs requiring rugged handling of large particles, or materials that are heated or have a potential for combustion.

BUCKET STYLES

Buckets are available in many shapes, sizes, and materials. Options differ depending on whether the unit is continuous or centrifugal. FEECO offers the following bucket styles:

- Style AA (Centrifugal)

- Style AC (Centrifugal)

- Medium Front (Continuous)

- High Front (Continuous)

- Super Capacity (Continuous)

For additional information on bucket styles, see Bucket Style Selection.

FEECO is capable of meeting the requirements necessary for CE marking equipment.

All FEECO equipment and process systems can be outfitted with the latest in automation controls from Rockwell Automation. The unique combination of proprietary Rockwell Automation controls and software, combined with our extensive experience in process design and enhancements with hundreds of materials provides an unparalleled experience for customers seeking innovative process solutions and equipment. Learn more >>

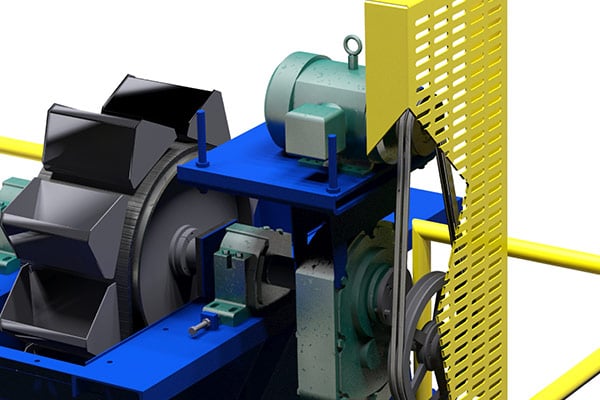

BUCKET ELEVATOR COMPONENTS AND PARTS

The image below shows the standard components of a self-supporting bucket elevator. A full range of custom options is available to increase the flexibility and performance of the unit in its intended application. Click image to view larger.

Mechanical Construction of a Bucket Elevator (3D Bucket Elevator by FEECO International)

A – Heavy-Duty Roller Bearings

B – Drive Motor

C – Gear Reducer

D – Gusset Plates

E – Specially Designed Head Frame

F – Heavy-Duty Angle Iron

G – Horizontal Crimp Stiffeners

H – Inlet/Feed Chute (not visible)

I – Gravity Take-up Assembly

J – Chain & Bucket Assembly

K – Elevator Casing

L – Discharge Chute

M – Inspection Door

N – Head Sprocket Assembly

APPLICATIONS

Self-supporting, bucket elevators can be employed in any industry from chemicals and agriculture settings, to mining, and everything in-between. Generally, they are not suited for wet, sticky materials, or those that are stringy or tend to mat or agglomerate. Because of their extreme throughput, the super-capacity, self-supporting bucket elevators are typically reserved for extremely high tonnages, such as those found in the potash industry.

Not sure what is right for your project? Contact us today: We can guide you through the process of evaluating the bucket elevator as an option, as well as selecting the most appropriate configuration.

RESOURCES

Bucket Elevator ARTICLES

Elevator Bucket Style Selection

Whether purchasing a new bucket elevator or re-configuring an existing one, proper elevator bucket style selection is a key aspect of …

Engineering Potash Bucket Elevators for Longevity

Bucket elevators are essential for handling potash at various stages of processing, storage, and distribution. From mining and ore processing to …