After decades of production, rotary kilns used for calcination in catalyst plants and manufacturing facilities are reaching the end of their service life.

Producers looking to replace their aging calcination equipment are quick to order a duplicate system, but what many don’t realize is that their existing kilns were originally designed to be over-size.

As a result, producers can incur substantial cost savings by optimizing the size of their replacement kiln, something FEECO has proven in a number of plants already.

FEECO Indirect Kiln

Optimizing Kiln Size Through Loading

Calcination plays a critical role in catalyst preparation, chemically “curing” catalysts for maximum performance in their end use. Several parameters are carefully balanced during the calcination process to ensure catalysts meet a number of predetermined quality characteristics.

One of the most influential aspects when it comes to kiln efficiency comes down to the loading, or the volume of material running through the kiln at any given time. Also referred to as material fill, loading has significant implications on the physical size of the unit.

While other industries use around 10% material fill, the catalyst industry has historically used much smaller loading, around 3%, likely because the collective understanding of advanced thermal processing techniques has advanced so much over the years.

While this low-loading approach has indeed worked and produced the desired results, it is significantly inefficient; a low loading means the kiln processes less material, requiring more production hours to achieve the desired throughput.

As a leader in custom rotary kilns, FEECO has been working with catalyst producers to optimize the size of their replacement kilns for maximum efficiency, largely through increased loading.

Benefits of Increased Kiln Loading

By increasing kiln loading and sizing the unit more appropriately, producers are able to garner substantial cost savings in two key areas:

Increased Capacity

A greater throughput means producers can increase their capacity or reduce their operating hours, which can also mean lower labor and operating costs.

Lower Capital Cost

A smaller unit reduces the capital cost of the equipment. This also equates to a smaller equipment footprint on the production floor.

Confirming the Calcination Process

Many catalyst producers are understandably hesitant to consider resizing their kiln when what they already have has worked reliably for decades.

While fears of muddling the process and potentially curtailing production are understandable, these risks are easily avoided by working with a manufacturer that can test the increased loading and illustrate proof of process in a controlled environment.

Such test work is regularly conducted in the FEECO Innovation Center, where several test rotary kilns allow producers to trial increased loading at both batch and pilot scale.

Because of the accuracy of our in-house testing facility, we are able to offer process guarantees, meaning catalyst manufacturers have peace of mind in knowing their new system will produce a quality product at the capacity needed.

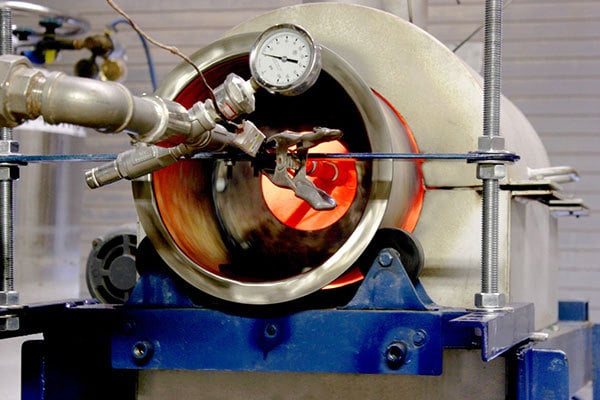

Batch-scale indirect kiln used for catalyst testing in the FEECO Innovation Center

Pilot-scale indirect kiln used for catalyst testing in the FEECO Innovation Center

A Note on Catalyst Preparation

In addition to rotary kiln testing, the Innovation Center also offers testing for agglomeration (wet granulation), drying, and even coating, so catalyst producers have everything they need at their fingertips to ensure a quality product.

Catalyst regeneration (reactivation) and the recovery of valuable components can also be tested.

Bringing Rotary Kiln Designs to Life

In addition to the Innovation Center, another major advantage to producers is FEECO’s on-site manufacturing facility. Process experts, engineers, and production personnel are able to work collaboratively to transform test results from the Innovation Center into a commercial-scale unit that performs exactly as expected.

Conclusion

As the catalyst industry continues to upgrade aging production equipment, producers can garner substantial cost savings by resizing their rotary kilns for optimal efficiency. By increasing kiln loading, producers are able to increase capacity and reduce the capital cost of their replacement unit, a process that can be proven in a test facility such as the FEECO Innovation Center.

FEECO has become the catalyst industry’s choice for bringing advanced thermal processing techniques to life through our custom rotary kilns and process development services. We also offer extensive parts and service support to keep catalyst kilns running optimally, whether they were manufactured by us or not. This includes process audits, provision of spare parts, refurbishment, and more. To discover how we can optimize your process while minimizing costs, contact us today!