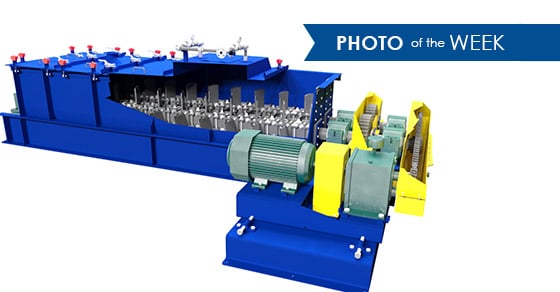

This week’s photo highlights a pugmill mixer, also known as a paddle mixer, in 3D. The image was created by FEECO’s CAD Specialists.

Pug mills are comprised of two counter-rotating shafts fastened with pitched paddles. The paddles use a high-torque, kneading and folding over motion to create an intimate mixture of materials. They are particularly adept at processing heavy duty materials, accommodating mixes of solid and liquid feeds.

Typical pugmill mixer applications include:

- Mixing: pigments, municipal sludge, fly ash

- Agglomeration: carbon powders, fertilizers, agricultural chemicals

- Conditioning: iron-oxide, foundry dust, zinc oxide

FEECO has custom designed and manufactured pugmill mixers since our founding in 1951. We not only manufacture the equipment, but also provide testing, as well as service and maintenance post-sale.

For a more in-depth look at FEECO’s experience with pugmill mixers, download our e-book, or contact us today!