Trough conveyors are perhaps the most universal type of equipment employed across industries; handling everything from aggregates and minerals to chemicals and fertilizers, one would be hard pressed to find a facility not employing trough conveyors in their bulk material handling endeavors.

The trough conveyor industry is expansive, and while the number of manufacturers does provide diversity in selection, it often makes choosing the right conveyor manufacturer a challenge. Below are the key factors to consider when selecting a trough conveyor manufacturer.

Finding the Right Trough Conveyor Manufacturer

Several factors should be considered in evaluating potential suppliers:

Flexibility in Customization

One-size-fits-all trough conveyors pervade the bulk material handling equipment market, promising efficient, trouble-free handling. But as anyone who works in a facility where bulk solids are handled can attest to, a one-size-fits-all approach is not appropriate outside of low-value, light-duty applications.

All materials present unique challenges in handling, requiring a manufacturer that can design trough conveyors around those challenges to yield the most efficient and reliable handling solution possible.

In selecting a conveyor manufacturer, ensure the manufacturer recognizes this need for flexibility and is prepared to meet such challenges through thoughtful, custom belt conveyors.

Trough Conveyors with weather covers for protecting material

Material Experience

The material to be handled will dictate many aspects of trough conveyor design. Parameters such as a material’s bulk density, particle size distribution, moisture content, angle of repose, and so forth, will influence decisions throughout the engineering and design process.

As such, it is important to select a conveyor manufacturer that has a diverse handling background, allowing them to provide expertise in unique handling challenges and expertly tailor equipment to work with the material in the most effective way possible.

Ultimately, this will minimize downtime and maintenance costs, and reduce the many headaches associated with an under-performing system.

During the selection process, ask short-listed candidates for project profiles, references, or other materials that illustrate proven success stories.

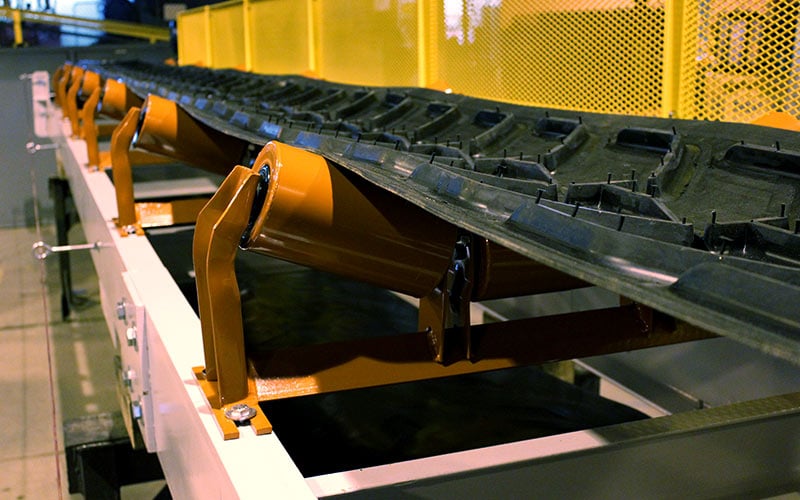

Trough conveyor with cleated belting designed to keep material on the belt when conveyed on an incline

High-Quality Fabrication

Conveyors operate in harsh environments and are often tasked with extremely demanding workloads. Given that an offline conveyor can put an entire operation at a standstill, reliability is essential.

For this reason, priority should be given to manufacturers that follow strict quality standards in both design and fabrication. Materials of construction, welding procedures, and more, should all be focused on achieving a lasting, durable product that minimizes wear and downtime while maximizing production.

FEECO Conveyor head section with shaft-mounted reducer and top-mounted motor (with high-speed V belts)

Ongoing Support

In high-value or high-capacity production settings, the cost of downtime and potential losses represent significant risk, making avoiding unexpected outages a top priority. Just as equipment quality plays a critical role in preventing unnecessary down time, so too does maintenance, and even the most well-built conveyors must be maintained to provide efficient and reliable performance in the long term.

Be sure to select an original equipment manufacturer (OEM) that will stand behind their work, providing tailored support, from conveyor inspections and routine maintenance, to spare parts and troubleshooting services. This support often makes the difference in minimizing downtime when it happens.

Conclusion

Trough conveyors are the backbone of many industrial processes, and as such, should be efficient, reliable, and built for long-term performance. In selecting a conveyor manufacturer, look for OEMs that not only provide a customized solution based on expertise, but that also have a comprehensive parts and service support program as well.

FEECO is a leading provider of custom bulk material handling equipment, including troughed belt conveyors bucket elevators, and more. Our extensive experience in numerous production settings and with a broad range of materials allows us to engineer optimized handling systems for any setting. Our Customer Service Team supports you by keeping them running their best. For more information on our trough conveyors, contact us today!