One of the most essential rotary drum maintenance procedures in prolonging service life is tire and trunnion grinding – the practice of resurfacing the tire (riding ring) and trunnion wheel components to like-new condition. Since damage to these components has a compounding effect on the rest of the drum, keeping tires and trunnion wheels in good condition is the starting point for avoiding more severe issues.

Newly installed rotary drum tire and trunnion wheel

Consequences of Tire and Trunnion Wear

As the drum’s foundational support, problems that start in the tires and trunnion wheels work their way to other parts of the drum if not promptly addressed. Worn tires and trunnions can have a variety of causes, but when left untreated, the resulting stress on other components continues to build, exacerbating existing issues and promoting more severe damage.

This can have a range of consequences, from drum misalignment to vibration amplitude, and even improper load distribution.

Misalignment

Rotary drum alignment is a primary contributor to overall drum performance and longevity. Much like tires and trunnion wheels, the alignment of a drum affects several components, and when allowed to run out of alignment, can result in a wide range of problems.

While there are many potential consequences of misalignment, one especially challenging result is the lack of control over axial thrust. The inability to properly manage axial thrust promotes excessive wear on one of the thrust rollers, which has the potential to cause thrust roller bearing failure. In turn, bearing failure can lead to the drum dismantling the thrust roller shaft. If dismantling of the thrust roller shaft occurs, the drum is able to roll off the trunnion rollers, causing catastrophic failure and severe damage to breechings, seals, trunnion base weldment, concrete piers, gears (or chain and sprocket), tires, and the drum shell.

Drum Vibration Amplitude

Drum vibration amplitude should be kept at a minimum in order to keep the drum running as smoothly and efficiently as possible, minimizing stress on all components. Excessive vibrations not only cause undesirable chattering, but they also quickly propagate to the rest of the drum, causing:

- Hot trunnion bearings, and ultimately, bearing failure

- Trunnion shaft failure

- Damage to the inlet and/or discharge breechings

- Cracks to the concrete piers

- Damage to the gears, or chain & sprockets

- Premature refractory failure in kilns

Allowing a drum to run with an increased vibration amplitude will eventually lead to catastrophic failure. A vibrations study can be performed to measure the vibration amplitude (peaks) and determine how aggressive the vibrations are. Vibration amplitude assesses the amount of displacement occurring, measured in micrometers (µm).

Improper Load Distribution

A rotary drum is supported at four points where the tires (riding rings) meet the trunnion wheels. These four points of contact bear the weight of the drum and must be carefully balanced to provide even weight distribution and avoid putting excess strain on any of the components.

When additional load is put on the thrust roller(s), excessive loads are subsequently added to the drive components, resulting in increased shell vibrations.

Signs of Wear

As can be seen, addressing tire and trunnion wear is critical to the overall longevity of the drum.

Wear on tires or trunnions may take the form of any of the following patterns:

- Washboarding

- Spalling

- Pitting (an orange peel-like appearance)

- Rolled-over edges

- Timing marks

- Ridges

- Tapering

Tire wear caused by excessive skewing

Additionally, wear may also be indicated by a chattering or vibration sound. Furthermore, wear on one component (the tire or trunnion) is typically mirrored on the corresponding component, but this does not hold true in all settings. Any sign of wear, whether on one or both surfaces, should be immediately addressed.

The Tire & Trunnion Resurfacing Process

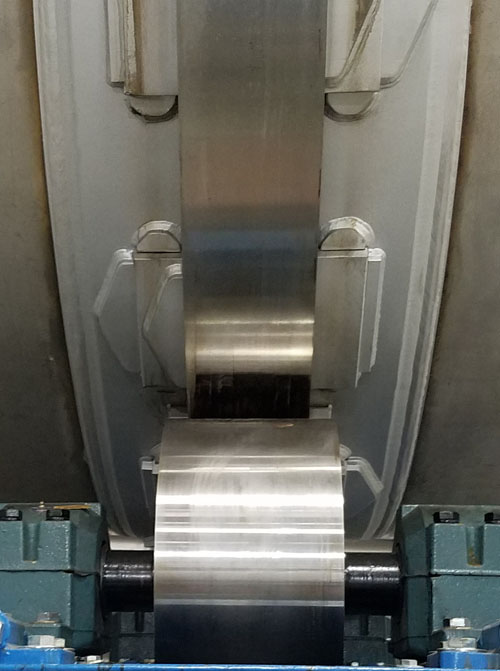

Sometimes called reconditioning, tire and trunnion wheel grinding is a relatively simple process in which trained technicians use a specialized grinding machine to remove any surface wear to reveal the undamaged surface underneath.

Depending on the severity of the wear and the diameter of the wear surface, this process may take anywhere from a few hours to a few days. In many cases, the drum can remain in operation during the grinding process, so production need not be affected.

If wear exceeds greater than 10% of the original diameter, FEECO recommends replacement of the component to avoid problems associated with an altered slope, which can have larger ramifications on the overall process.

Tire grinding in progress

Tire and Trunnion Wheel Grinding Preparation

Customers in need of tire and/or trunnion grinding will be asked to provide the following in preparation of the service visit:

- 460 volt, 3 phase power, electrician and hardware for connections.

- 40 feet of 2 “x 2″ x 1/4” angle iron.

- 20 feet of 1″ x 1″ x 1/8″ angle iron.

- Crane or lifting capabilities for up to 2000 lbs.

- Adequate restroom facilities and telephone for supervisor company calls

- Removal of any supports, brackets, guards, etc. which prohibit the placement of the grinding equipment.

- Adequate lighting and ventilation as needed.

- A clean, safe, and accessible work environment at the job site.

- Solid surface free from vibrations and dust-free environment for laser alignment system

- Shim material by customer as necessary.

- Drum Speed to be approx. 100FPM tire surface speed.

Post-Grinding Alignment

While resurfacing tires and trunnion wheels provides an immediate improvement, this improvement is only temporary if the drum is not realigned following resurfacing (any major repairs or replacements require realignment to ensure the drum load is properly distributed and mechanically stable).

If the drum were not aligned following grinding, the misalignment of the drum, however minuscule, would immediately begin causing wear to tires and trunnion wheels, bringing them back to their pre-grinding condition.

While manual methods are available, rotary drum alignment is typically carried out using a laser alignment system. This advanced system reduces potential for human error, improves accuracy, and speeds up the alignment process.

Conclusion

Tires and trunnion wheels serve as the support system for a rotary drum, and as such, have a compounding effect on the system if allowed to wear. Tire and trunnion wheel grinding is a critical preventive maintenance tool in prolonging rotary drum life and promoting efficiency.

FEECO is a leader in rotary drum maintenance for dryers, kilns, coolers, and agglomeration drums. Our Customer Service Engineers can assess damage to load-bearing surfaces, as well as resurface tires and trunnions quickly and accurately. They can then realign the drum for optimum mechanical stability. FEECO can also provide replacement tires and trunnions in cases of severe wear. For more information, contact our Customer Service Team today!