Acid roasting of spodumene occurs after the ore has been through decrepitation, or the conversion from alpha to beta form. Spodumene concentrate is mixed with sulfuric acid and roasted as part of the conversion to lithium compounds.

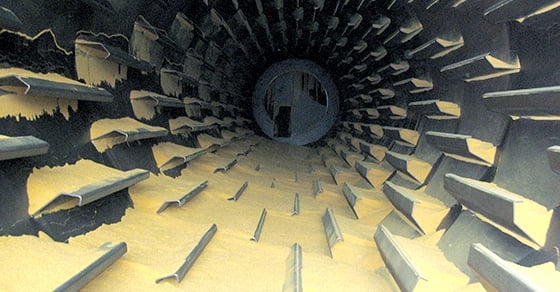

THE ACID ROASTING PROCESS

Acid roasting is carried out through calcination in a rotary kiln at temperatures around 250º C. This calcination step allows lithium to be extracted as water-soluble lithium sulfate.

CUSTOM ACID ROASTING KILNS

Rotary kilns used in the acid roasting process are of the indirect-fired configuration, because beta-phase spodumene cannot come into contact with the products of combustion as it would in a direct-fired kiln.

FEECO designs and fabricates the industry’s best custom indirect-fired kilns for use in the acid roasting process.

SERVICES

As a leader in advanced thermal processing methods and equipment, FEECO is able to offer comprehensive support for every aspect of the acid roasting process, from concept to optimization. In addition to custom equipment design and manufacturing, our services include:

BATCH/FEASIBILITY AND PILOT-SCALE TESTING

The FEECO Innovation Center is a unique testing facility where we can test your material at both batch and pilot scale in order to work out process variables and design commercial-scale units, as well as scale up the process.

This makes a thorough batch and pilot testing program essential to achieving the highest quality activated carbon possible.

Feasibility/Proof of Concept: An initial, non-witnessed batch testing phase in which the possibility of creating a product is explored.

Proof of Product: A more in-depth batch testing phase in which more time is spent determining whether a product can be made to desired specifications.

Proof of Process: A continuous testing phase that aims to establish the equipment setup and parameters required for continuous production of your specific material.

Process/Product Optimization: An in-depth study to optimize your specific material’s characteristics and/or production parameters in an industrial setting.

PROCESS TRAINING

Our extensive experience in processing hundreds of materials and derivatives leaves us unmatched in industry knowledge. Our Process Engineers travel the world to train our customers on their unique production line.

PARTS & SERVICE

The FEECO Customer Service Team provides comprehensive services to keep your equipment and process running reliably and efficiently. This includes:

- Process optimization

- Audits and inspections

- Spare parts

- Maintenance procedures

RESOURCES

LITHIUM ARTICLES

Ensuring A Smooth Rotary Drum Installation

A rotary drum, be it a dryer, cooler, agglomerator, or otherwise, is a major investment and integral part of many industrial …

Rotary Cooler Frequently Asked Questions (FAQs)

Rotary coolers are essential tools in industrial processing facilities across the globe, cooling product for subsequent handling, storage, or bagging. How …