In rotary kiln engineering, dams are often an overlooked yet critical component in controlling material retention and thermal efficiency. These strategically placed internal structures help engineers fine-tune process performance, making them an essential part of kiln design—particularly when processing solids that require extended retention times or precise thermal exposure.

Dams are also a practical tool for modifying process conditions in existing kilns that are not meeting performance goals. By retrofitting or adjusting dam configurations, engineers can improve residence time, reduce energy waste, and correct issues such as incomplete reactions or insufficient material drying—all without the need for costly equipment overhauls.

By adjusting retention time and heat transfer dynamics, dams enable engineers to:

- Optimize thermal exposure of the material

- Improve heat utilization by increasing the volume of solids in the kiln

- Prevent premature discharge of under-processed material

- Control bed depth for more uniform processing

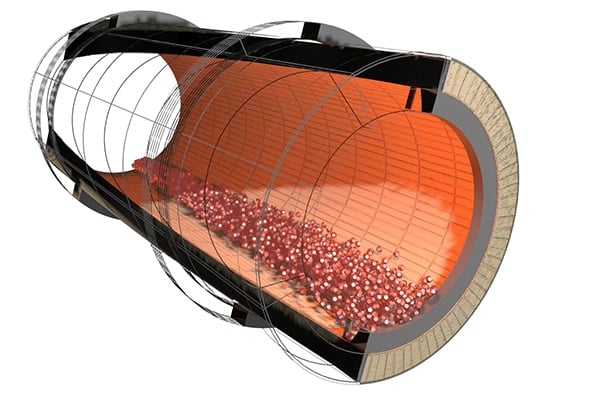

|

| 3D Rendering of a dam at the discharge end of a rotary kiln |

Dams in Direct vs. Indirect-Fired Kilns

Dams are used in both direct- and indirect-fired rotary kilns, though their purpose and design differ depending on the heating method and process conditions.

Direct-Fired Kilns

In direct-fired kilns, where material is exposed directly to combustion gases, dams are frequently used to:

- Increase material residence time for better reaction completion

- Maintain a deeper bed for more efficient heat transfer by conduction

- Prevent material from discharging before reaching the target temperature

Due to the harsh thermal and abrasive conditions often present, dams in direct-fired kilns are typically constructed from high-temperature alloy steels or castable refractory and may be reinforced to withstand high heat and material wear.

Indirect-Fired Kilns

In indirect-fired kilns, heat is applied externally to the shell, and the material does not come into contact with combustion gases. In these systems, dams are used more selectively. Common applications include:

- Improving material retention in low-throughput or sensitive thermal processes

- Promoting better material distribution

Since these kilns operate under gentler thermal and mechanical conditions, dam design can be simpler—retaining rings or low-profile dams are often sufficient. However, caution must be taken not to restrict flow excessively, as it can interfere with uniform heating.

Types of Dams and Their Design Applications

The specific dam design chosen depends on the material characteristics, process goals, and kiln configuration. Common dam types include:

Bolt-On Dams

Bolt-on dams are the most widely used type and are installed at the kiln’s discharge end. These fixed structures are either bolted or welded to the kiln shell or refractory lining. Their straightforward construction and ease of installation make them a preferred option in many applications.

Key Benefits: Durable, customizable, and replaceable

Retaining Rings

Retaining rings are less obstructive than full dams and are typically used to control the flow of smaller volumes or finer materials. These rings offer partial resistance to flow, encouraging slight bed buildup without significantly impeding throughput. They are ideal for use in indirect-fired kilns in low-volume specialty applications.

Key Benefits: Minimal obstruction, suitable for fine or sticky materials

Conical or Tapered Dams

These designs provide more gradual restriction and are often used when precise control of residence time is required without sharply reducing flow. The conical shape helps with material shedding and avoids excessive buildup that could lead to clogging or uneven wear.

Key Benefits: Smoother material flow control, less risk of clogging

Adjustable or Removable Dams

Though less common due to the challenges of high-temperature environments, some kilns feature adjustable dams to allow fine-tuning during pilot-scale testing or when processing variable feedstocks.

Key Benefits: Flexibility in process optimization

Design Considerations for Rotary Kiln Dams

When designing a dam, engineers must consider several interrelated factors:

Material Properties:

Abrasiveness, cohesiveness, particle size, and bulk density will impact both dam material selection and geometry. Highly abrasive materials may require abrasion-resistant linings or sacrificial wear plates on the dam.

Process Temperature

Since dams are located in high-temperature zones, material selection must ensure resistance to thermal stress and mechanical fatigue. Refractory-grade stainless steel or castable refractories are often used in dam construction.

Kiln Dimensions and Slope

The diameter, length, and slope of the kiln influence how material flows, and by extension, how aggressive the dam needs to be to achieve the desired residence time.

Rotation Speed and Fill Level

These parameters influence bed behavior. Higher rotational speeds or fill levels may necessitate taller dams to maintain effective retention.

Maintenance Accessibility

While dams are built for durability, they do require periodic inspection and, in some cases, replacement. Designs should facilitate access, especially in high-wear zones.

Thermal Implications of Dams

Beyond retention control, dams also affect the thermal profile of a kiln. By increasing bed depth, dams enhance heat transfer through conduction, allowing for better energy utilization and more efficient processing. However, over-retention can lead to localized overheating, sintering, or material buildup. Batch- and pilot-scale kiln testing are often used to identify the optimal dam size and placement for a given application.

Conclusion

Dams in rotary kilns are powerful tools in process control that can improve material retention, enhance heat transfer, and ensure product quality. Whether in direct- or indirect-fired systems, these components must be carefully engineered to meet the thermal, mechanical, and operational requirements of the application.

For engineers designing new kilns or looking to improve the performance of existing units, understanding the role of dams and how to leverage them effectively is essential to achieving operational and economic goals.