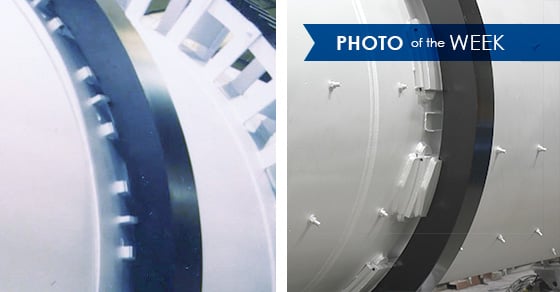

This week’s photo shows two different rotary drum tire mounting styles: the wedged and pinned mount (at left), and the floating mount (at right).

Traditionally, wedged and pinned mounts were used to mount the tire to the shell of the drum. And while they offer an effective mounting system, floating mounts are an improvement on the wedge system in certain applications, prompting many drum customers to make the switch to this optional style.

Floating mounts are particularly beneficial in high heat applications, or when large drums are used; wedged and pinned mounts cannot accommodate thermal expansion like a floating mount system can. Additionally, floating mount systems are more flexible than wedge mounts, which allows them to better preserve ovality in large drums.

FEECO Customer Service Engineers can retrofit a floating mount system to any wedge-mounted tire. If your rotary drum, be it a dryer, cooler, kiln, or granulator, is in need of a new tire, or tire remounting, this may be a good time to consider switching to the floating mount style. For more information, contact us today!