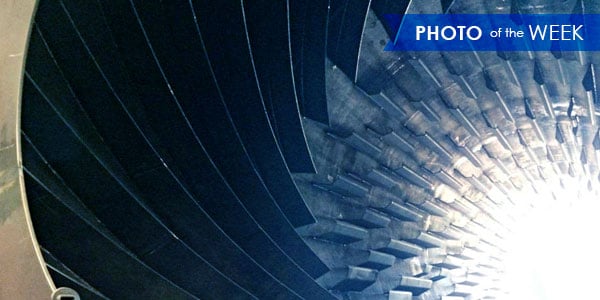

This week’s photo shows two types of flights in a rotary dryer: standard lifting flights, and advancing flights.

Flights, or lifters, are positioned inside the rotary drum and play a fundamental role in the drying process. As the drum rotates, flights lift the material, and then shower them through the heated air stream. This process maximizes heat transfer between the combustion gas and the material.

The advancing flights, shown in the very front of the drum, help to move the material through the first section of the drum, while giving pellets time to achieve surface drying and hardening before they are picked up and dropped by the lifting flights.

This is a common configuration for many types of materials, from gypsum to manures. Both flight design and flight pattern can be custom configured to suit the needs of the material being processed.

Whether you are drying sludge, fertilizers, minerals, or municipal wastes, FEECO can design a rotary dryer to fit your exact application.

For more information on flights or rotary dryers, contact us today!