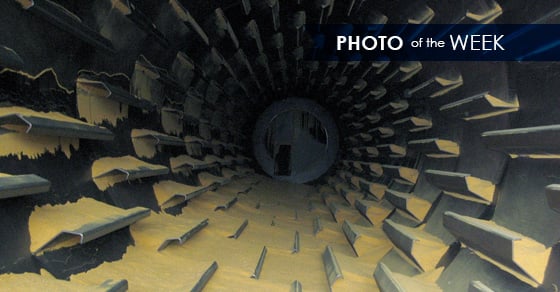

Today’s photo shows the interior of a rotary cooler.

The material inside of the cooler is dried distillers grains with solubles, also known as DDGS. DDGS is a is a by-product of ethanol production, and can be used as an animal feed ingredient due to its valuable energy and protein components.

Upon drying, DDGS in often cooled to avoid product caking during transportation or storage. Cooling the material can also reduce the potential for mold growth.

Today’s featured DDGS rotary cooler operates with a counter current airflow configuration. This airflow provides many benefits to the operation, including a lower discharge temperature, lower operating costs, decreased issues related to storage, and perhaps most importantly, a reduction of dryer energy requirements.

Flights are also fastened to the interior of the cooler, and they work by lifting the material up and dropping it through the chilled air stream while the drum rotates. This process maximizes contact between the material and chilled air.

FEECO has custom designed and constructed rotary coolers, like the one in this week’s featured photo, since our founding in 1951. To learn more, contact us today!