Phosphate processing equipment is essential in the production of phosphoric animal feed and fertilizer products. Further, its role continues to grow as producers increasingly look to improve upon their phosphate products and processing methods in the face changing market demands.

What follows is a basic overview of the equipment used in the production of animal feed and fertilizer products. Some equipment features may be specific to FEECO International.

Basic Requirements for Phosphate Processing Equipment

Phosphate processing equipment must be designed with the specific characteristics of phosphates in mind to reach an effective solution that will stand up to the rigors of processing phosphates while making the most out of this available resource.

Phosphate materials present a few challenges that must be considered in equipment design. Phosphates are often abrasive and corrosive, requiring special attention to materials of construction and fabrication techniques to avoid excessive wear on equipment and in severe cases, even premature failure.

They are also prone to clumping in the presence of moisture, which can lead to production challenges, buildup in equipment, and an exacerbation of abrasive and corrosive wear.

Further, phosphate rock is a finite resource – one that is irreplaceable and grows more important by the day as sources decline, making efficient processing critical to maximizing the world’s available supply.

For these reasons, it is vital to work with an original equipment manufacturer (OEM) well-versed in addressing the unique challenges phosphate processing equipment will face.

Key Phosphate Processing Equipment

Granulation Drums

Granulation drums are the centerpiece of most phosphoric fertilizer operations. This is where material is granulated after reaction.

Granulation drums are incredibly versatile and can therefore be used to process a wide array of materials. They are used frequently throughout the agriculture industry to create a variety of inorganic fertilizer products.

How Granulation Drums Work

In fertilizer production, granulation drums work by tumbling raw material in a rotating drum. As the material cools and solidifies, the tumbling action rounds it into granules. Tumbler flights can be added to increase material agitation and create the desired product characteristics.

Flexible and corrosion-resistant drum liners can be implemented to reduce or eliminate material build-up on drum walls, and decrease the potential for damage due to a corrosive material.

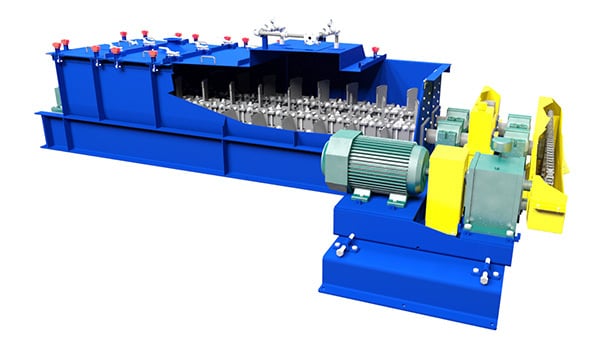

Pugmill Mixers

In the phosphates industry, pugmill mixers, also commonly known as paddle mixers or pug mills, are used in granular fertilizer production to mix the recycle with the new raw materials, and in animal feed production to thoroughly mix, react, and granulate feed ingredients.

How Pugmill Mixers Work

Pugmill mixers use a folding and kneading action to thoroughly mix solid and liquid feeds. In granular fertilizer production, they make a homogeneous blend prior to entering the granulator. In animal feed production, they facilitate the reaction between components. The thorough mixing helps to ensure a uniform product.

Rotary Dryers

Rotary dryers are used prolifically throughout the phosphates industry, for drying phosphate rock, as well as for drying granular animal feeds and fertilizer products.

How Rotary Dryers Work

Rotary dryers work by cascading material in a rotating drum in the presence of a hot gas. Material lifters, or flights, lift the material, carry it over, and drop it through the hot gas stream in order to maximize heat transfer efficiency.

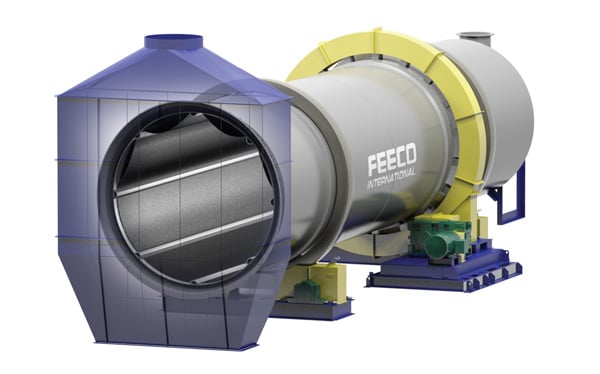

Rotary Coolers

The use of a rotary cooler is also typical in fertilizer granulation. A cooler is commonly used after the drying step to cool material exiting the dryer.

Cooling helps to bring down material temperature so it is not too hot for subsequent handling, and it also helps to prevent caking issues during storage.

How Rotary Coolers Work

Much like rotary dryers, rotary coolers cascade material in a rotating drum. Instead of heated air, however, they utilize chilled or ambient air. Here again, flights are necessary to increase heat transfer efficiency.

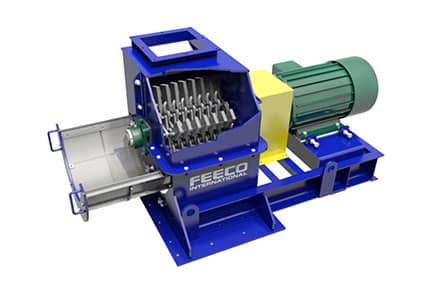

Hammer Mills

Hammer mills are used for both fertilizer and animal feed granulation applications for crushing oversize granules so they can be worked back into the process as recycle.

How Hammer Mills Work

Hammer mills use a spinning shaft affixed with hammers and/or chains to break down oversize product. Hammer mills produce maximum product in the size range of minus 4 mesh down to plus 20 mesh.

High-Speed Mixers

The high-speed mixer is specific to the FEECO approach to animal feed granulation and is the most efficient type of reactor/mixer in the marketplace today. The addition of a high-speed mixer to the pugmill mixer provides an improved reaction and a more uniform product.

How the High-Speed Mixer Works

The FEECO high-speed mixer is comprised of a vertical chamber, through which a shaft extends. The shaft is affixed with several paddles, and operates at 300-400 RPM to provide thorough mixing and initiate the reaction before material moves on to processing in the pugmill mixer.

Coating Drums

Coating drums are sometimes used in the production of MAP and DAP. Coating drums coat granules with a material that improves the end product in some way, typically by reducing dusting issues, employing an anti-caking agent, or incorporating a beneficial additive or micronutrient.

How Coating Drums Work

Similar to rotary granulators, coating drums consist of a rotating drum through which material is fed. The material tumbles through the drum, and a spray system releases the coating agent onto the material bed. Tumbler flights help to increase agitation, ensuring uniform results.

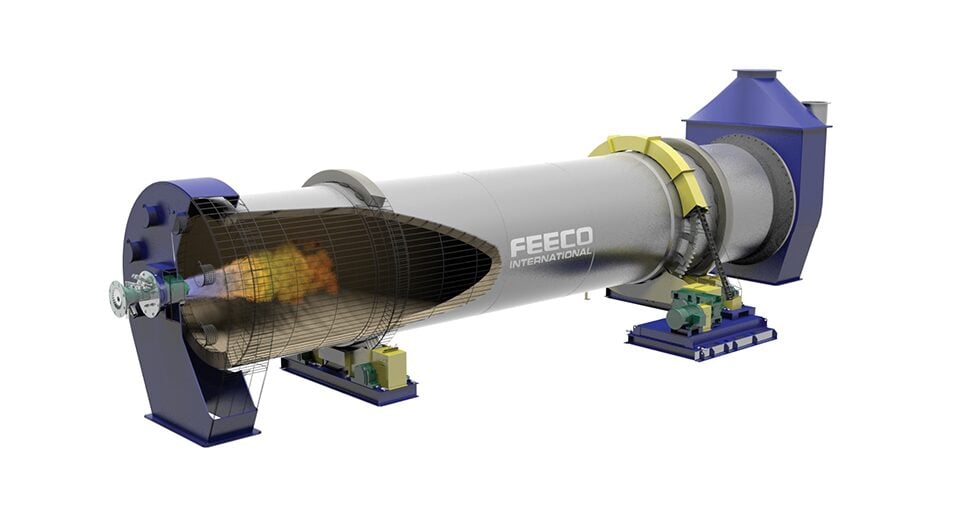

Rotary Kilns

Rotary kilns are similar to rotary dryers, but operate at much higher temperatures in order to cause a chemical reaction or phase change. In the phosphates industry, kilns are sometimes used to upgrade low-grade phosphate ore, or ore that would otherwise be considered contaminated.

How Rotary Kilns Work

Rotary kilns work by heating material to the temperature at which the desired reaction will take place, and holding it there until the reaction is complete.

Phosphate Handling Equipment

In addition to processing equipment, phosphate handling equipment is also a key component of a successful plant, connecting process steps and facilitating product movement both in and around the facility. This includes belt conveyors, bucket elevators, belt trippers and plows, as well as other critical equipment for moving material.

A Trusted Partner for Phosphate Processing Equipment

While the equipment used in processing phosphates is well established, it requires careful attention to detail to yield equipment that will not only process phosphates efficiently, but that will also stand the test of time under demanding conditions.

FEECO has been working in the phosphates industry since 1951, providing the best in custom phosphate processing equipment. From material testing and process development, to custom equipment and parts & service support, FEECO has all of your phosphate processing equipment needs covered. To find out how we can assist your phosphate processing operation, contact us today!