WHAT IS MICRO PELLETIZING?

Micro pelletizing is a particle size enlargement (agglomeration) technique used to transform bulk solids into small agglomerates, typically ranging in size from 20-60 mesh, thereby improving handling and application characteristics and reducing dust.

COMMONLY MICRO PELLETIZED MATERIALS

Micro pelletizing can benefit any material that presents handling challenges as a result of its powdered or fine texture. Materials that are frequently processed via micro pelletizing include:

- Chemicals and Process Additives

- Minerals (gypsum, limestone, etc.)

- Soil Amendments

- Fertilizers

- Industrial by-products (fly ash, FGD gypsum, etc.)

THE MICRO PELLETIZING PROCESS

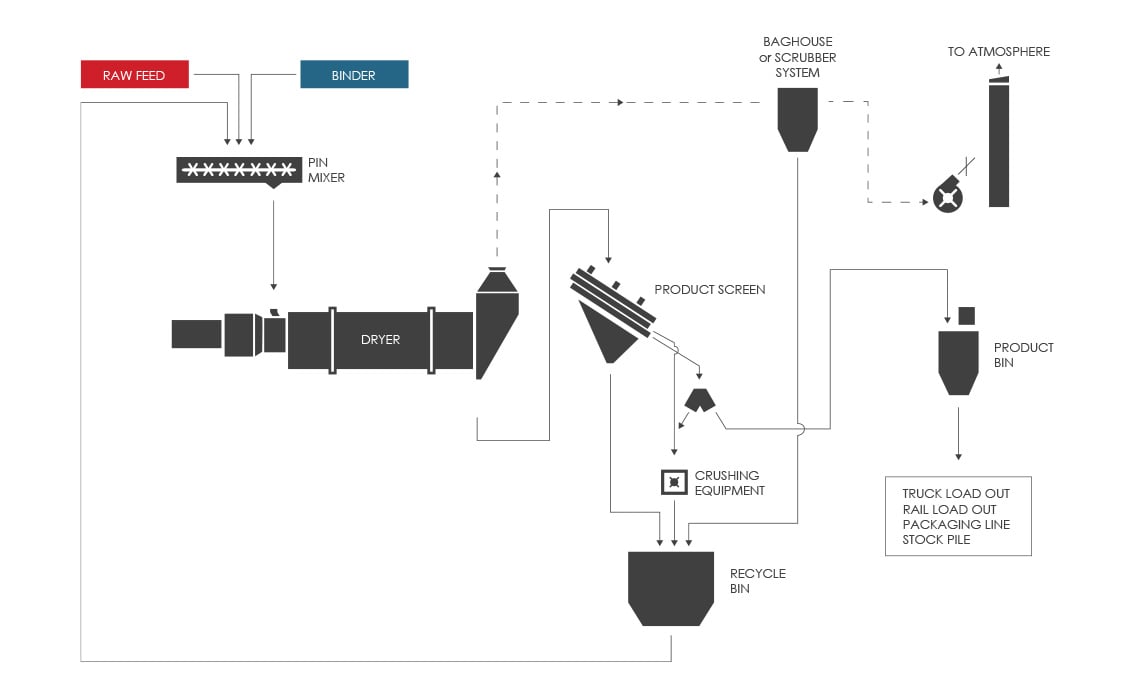

The micro pelletizing process may vary depending on the unique process and material goals. In general, however, a pin mixer is used to form the agglomerates, which are then dried and screened, as shown in the process flow diagram below.

Typical micro pelletizing process flow diagram

CUSTOM MICRO PELLETIZING EQUIPMENT

The pin mixer is an industrial mixer highly adept at processing ultra-fine materials in the presence of a liquid binder, producing homogeneous, dense agglomerates. The pin mixer is highly customizable and can also be used as a preconditioning step in a larger agglomeration process.

FEECO pin mixers are engineered and built around the precise application requirements to yield an optimal processing solution. More information on pin mixers >>

While pin mixers are the primary device of choice for micro pelletizing, on occasion, other equipment may be added to the process, or may replace the pin mixer. This might include:

- Rotary drums (aka, granulation or agglomeration drum)

- Disc Pelletizers

- Pugmill Mixers (Paddle Mixers)

SERVICES

As the global leader in tumble growth agglomeration, FEECO is able to offer comprehensive support for every aspect of the micro pelletizing process, from concept to optimization. Services include:

BATCH/FEASIBILITY AND PILOT-SCALE TESTING

The FEECO Innovation Center is a unique testing facility where we can test your material at both batch and pilot scale in order to work out process variables and design commercial-scale units, as well as scale up the process.

The FEECO Innovation Center can test on a single piece of equipment, or a continuous process loop, and can determine the process parameters necessary to meet exacting particle specifications.

We offer comprehensive testing services in four categories:

Feasibility/Proof of Concept: An initial, non-witnessed batch testing phase in which the possibility of creating a product is explored.

Proof of Product: A more in-depth batch testing phase in which more time is spent determining whether a product can be made to desired specifications.

Proof of Process: A continuous testing phase that aims to establish the equipment setup and parameters required for continuous production of your specific material.

Process/Product Optimization: An in-depth study to optimize your specific material’s characteristics and/or production parameters in an industrial setting.

PROCESS TRAINING

Our extensive experience in processing hundreds of materials and derivatives leaves us unmatched in industry knowledge. Our Process Engineers travel the world to train our customers on their unique micro pelletizing production line.

Parts & Service SUPPORT

The FEECO Customer Service Team provides comprehensive services to keep your equipment and process running reliably and efficiently. This includes:

- Process optimization

- Audits and inspections

- Spare parts

- Maintenance procedures

RESOURCES

MICRO PELLETIZING ARTICLES

What is Micro Pelletizing? Micro pelletizing is the process of agglomerating material fines into small pellets. Unlike traditional pelletizing, where slightly …

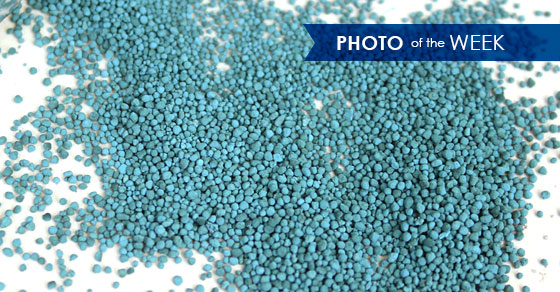

Photo of the Week: Micro-pelletized Paint Pigment Sample

This week’s photo highlights a micro-pelletized paint pigment sample from FEECO’s Innovation Center. Micro-pelletizing is the practice of agglomerating material fines …