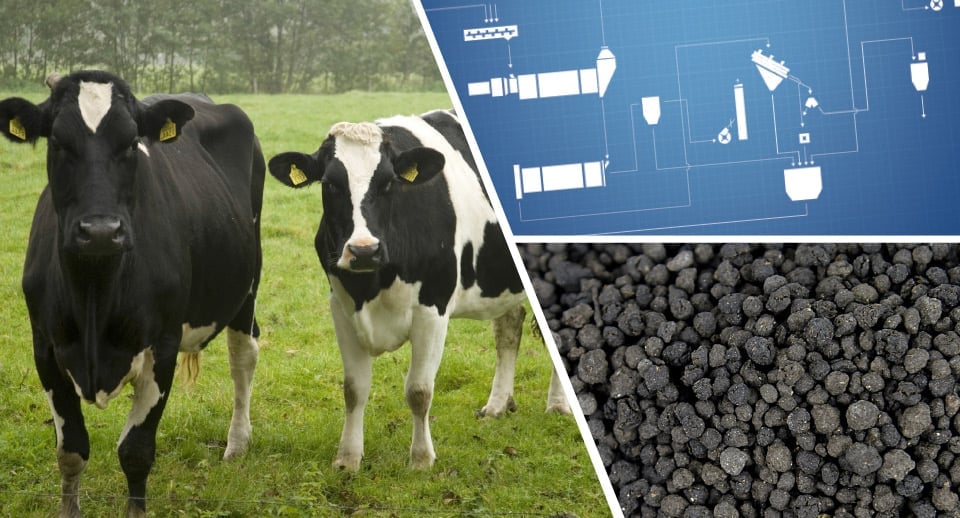

Manure poses significant challenges for large-scale farms. An increasing population has put mounting pressure on the agriculture and livestock industries to provide more food. Herd sizes continue to grow, while prohibitively high land costs and surrounding land development are reducing the available farmland for waste disposal. Additionally, the high cost associated with transporting manure discourages hauling manure to land farther than a few miles from the farm.

Recent research has shown that nutrient runoff from land application of manure has caused ground and surface water contamination in many areas. When nutrient runoff occurs, the farmer is not able to reap the full nutrient benefits from his fertilizer, resulting in a loss of value.

Conversion to a manure-based granular fertilizer product alleviates all of these issues, offering numerous benefits to the soil and delivering economic value back to the farmer.

MANURE GRANULATION FROM RECOVERED NUTRIENTS

Granulation occurs after nutrients have been captured from the manure (this step is often referred to as nutrient recovery). Depending on the type of manure and many other factors, nutrients are typically captured through anaerobic digestion followed by solid-liquid separation. The result is a nutrient-rich cake ideal for granulation in both nutrient content and feedstock characteristics.

FEECO offers a unique approach to the granulation of manure that is highly customizable to the manure source being processed and the desired end product characteristics. The end result is a cutting-edge fertilizer production system that converts manure into a premium granular fertilizer product** that minimizes odor and has little attrition.

Our proven technologies are backed by our international reputation in providing the best in fertilizer production equipment and complete process systems. Nearly every major player in the fertilizer industry trusts FEECO for their equipment and process design needs, including:

The Manure Granulation Process

A common approach to granulating digestate cake (i.e sludge) is to run the digested manure cake through a pugmill mixer, along with dried fines/recycle and any additional desired inputs. The mixer combines the solid and, if applicable, liquid components into a homogeneous blend, forming rough granules.

These granules are then fed to a rotary dryer, which reduces the moisture content of the material while also further polishing granules. A fluid bed dryer can be used as an alternative to a rotary dryer.

The dried material is fed to a rotary cooler where the product is cooled for bagging, storage, or transport. Product is screened, with any oversize material being crushed down and fed back into the system with under-size material as recycle.

This approach is illustrated in the simplified process flow diagram below. This approach is ideal for dairy farms, where farmers can optionally dry the removed coarse fibers from solid-liquid separation for use as a freestall bedding (this product is known as Dried Manure Solids, or DMS).

A Note on Capacity: While FEECO can accommodate nearly any capacity, typical capacity ranges from 5 to 10 TPH of product, or 20 to 40 TPH of raw cake feedstock.

BENEFITS TO GRANULATing Manure

The granulation of manure offers a number of benefits, both economically and environmentally:

Improved Product Handling

Granules are more easily handled, transported, and applied than raw manure or digestate cake.

Reduced Waste Management Costs

Dry granules can be stored on-farm and are much less costly to transport than raw manure.

Reduced Runoff

Dry granules aid in the prevention of runoff, because they are used only as needed, and do not add additional moisture to the soil, which can increase the opportunity for runoff to occur.

Premium Product

Additives can be included in the process to create custom products and fertilizer blends, allowing the product to be tailored to specific soil needs and nutrient management programs, or to be sold as a premium product.

Enhanced Nutrient Management

Granular fertilizers make it easier to effectively follow and monitor application rates for a nutrient management program. A granular product is also a valuable tool in precision agriculture applications, where it provides improved dispensing capabilities.

RESOURCES

PROJECT PROFILES

NUTRIENT RECOVERY ARTICLES

Rise in Anaerobic Digestion Boosts Manure Granulation

The rising adoption of anaerobic digesters for food waste and on-farm use is bringing food production another step closer to a …

Options in Pre-Conditioning Organics for Granulation

The practice of granulating organic wastes such as manure has seen an influx of attention in recent years, due to the …