Potash coolers play a key role in the potash manufacturing process, helping producers bring their products to market efficiently and effectively. And while cooling is a relatively straightforward task, it is still a large undertaking requiring flexibility and expertise in order to consistently and reliably meet process and product goals.

Why Use a Potash Cooler

Potash coolers provide a number of advantages that translate to an improved product.

Benefits of Cooling Potash Include:

Increased Potash Process Efficiency

Adding a cooler to the manufacturing process offers facilities the ability to handle, bag, and store potash immediately, avoiding other time-consuming cooling methods.

Reduced Potash Storage Issues

Cooling potash before bagging prevents issues such as sticking or caking during storage.

Enhanced Potash Granule Robustness

The process of cooling potash creates a more resilient final product that is less likely to wear down as granules come in contact with each other.

Options for Potash Coolers

Rotary coolers and fluid bed coolers are standard potash cooling equipment. In general, both options handle material gently and avoid attrition, key qualities in industrial cooling equipment. However, they each offer unique advantages to the potash cooling process.

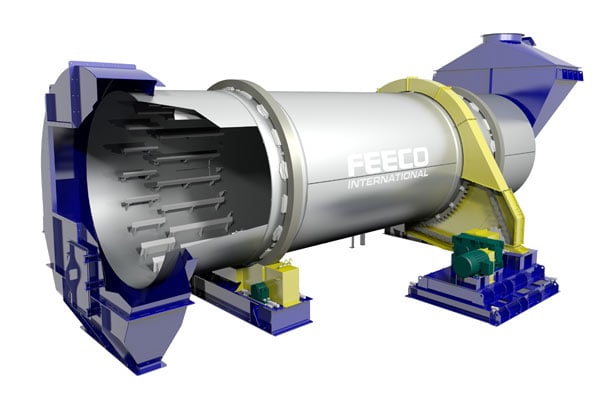

Rotary Coolers

Rotary coolers are robust, long-lasting, and capable of accepting a wide range of feedstock when cooling potash. In general, a standard rotary cooler is much larger than a fluid bed cooler. Because of its greater size, a rotary cooler is able to handle a higher material volume, making it an ideal choice for potash processing facilities running at a high capacity. The heavy-duty construction of a rotary cooler is especially suitable for handling potash.

How Rotary Coolers Work

As with a rotary dryer, a rotary cooler consists of a rotating drum set on a slight angle to allow gravity to assist in moving material through the unit. As the drum rotates, flights within the cylinder lift the potash and shower the material through a counter-current ambient or chilled air stream. This method, along with FEECO’s high-quality manufacturing capabilities, has been proven effective in the potash industry for years. While not as gentle as a fluid bed cooler, the tumbling action within the drum benefits the material by further polishing granules.

Fluid Bed Coolers

How Fluid Bed Coolers Work

Fluid bed coolers work by suspending material in a stream of air or gas, efficiently cooling potash by exposing the entire material surface to air. This method also provides gentle material handling, reducing erosion and wear between potash granules, though some attrition is still possible.

Due to their smaller size, fluid bed coolers process material at a lower throughput compared to rotary dryers, but are ideal in facilities with limited space.

Conclusion

Cooling is an essential step in the production of potash products, allowing for safe and efficient handling and storage. The choice between process cooling systems often comes down to rotary coolers and fluid bed coolers, with each offering their own advantages.

As a preferred provider to the potash industry since 1951, FEECO manufactures custom rotary coolers that are built for longevity and backed by our comprehensive parts and service support. For more information, contact us today!