The objective shared by incline conveyors and steep incline conveyors – to convey bulk solids on an incline – often presents confusion in determining which type of conveyor is best for a given application.

While both offer an effective handling solution, these two conveyor types operate and are designed very differently, making the selection between the two dependent on a few key factors. In an effort to make the choice between the two more clear, we’ve outlined the primary differentiators between incline conveyors and steep incline conveyors here.

Key Considerations in Choosing Between an Incline Conveyor and Steep Incline Conveyor

Angle of Transport

Both incline conveyors and steep incline conveyors serve to convey material on an angle to some extent. The key difference between these two conveyor types, is the angle at which they can transport material.

A typical incline conveyor is simply a troughed belt conveyor positioned on an incline (or decline). Troughed belt conveyors are generally not effective at inclines greater than 18 degrees, as material slippage on the belt becomes a major concern. Conversely, steep incline conveyors can convey material at inclines up to 90°.

Spatial Footprint

One of the most common reasons for selecting a steep incline conveyor over an incline conveyor is the smaller spatial footprint.

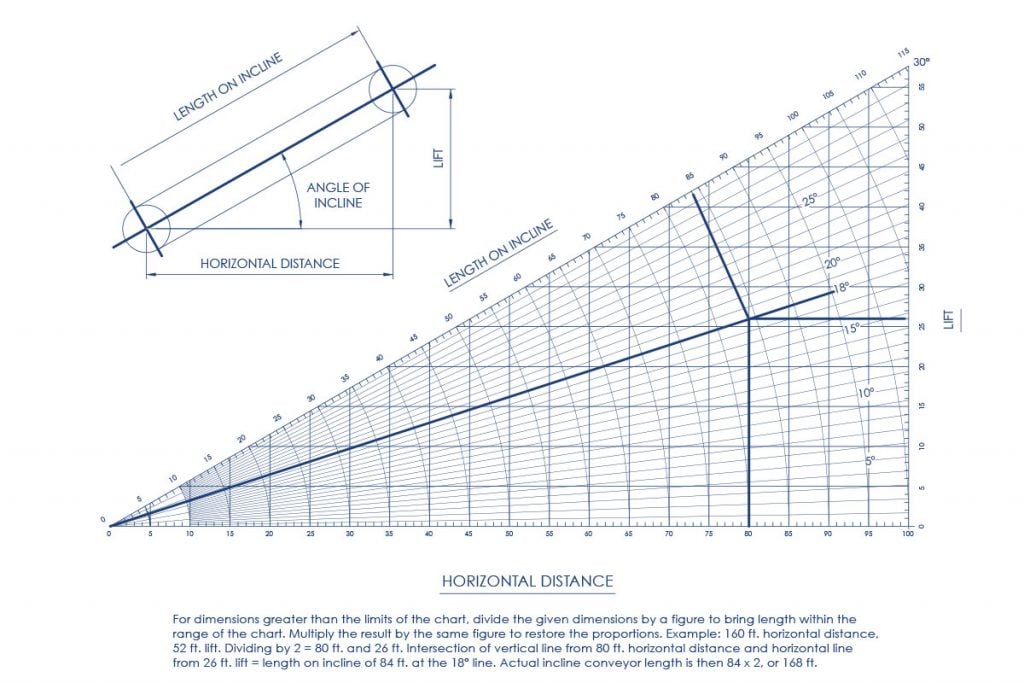

Incline conveyors require a specific amount of conveyor length to reach the desired amount of lift (see chart below). In other words, if a steep incline conveyor is not used, the greater the amount of lift, the longer the conveyor will need to be in order to convey the material at an angle that promotes optimal handling.

Because steep incline conveyors can efficiently move material at a steeper angle, however, the overall length is significantly reduced. As such, steep incline conveyors take up considerably less space than a standard troughed belt conveyor positioned on an incline.

The chart above illustrates the distance/length requirement for the level of incline on an inclined conveyor.

In addition to a lower profile, the L and S configurations of the steep incline conveyor allow it to replace multiple pieces of handling equipment; one S-type steep incline conveyor (shown below) can replace two belt conveyors and a bucket elevator, significantly reducing the overall footprint of handling equipment.

Transfer Points

Because steep incline conveyors can combine horizontal and vertical handling through the L and S configurations, therefore replacing multiple pieces of handling equipment, the need for additional transfer points that would otherwise be necessary is eliminated.

This reduction in transfer points can be a major benefit, as it lessens the potential for material degradation and dust generation by providing a continuous conveying solution.

Though steep incline conveyors generally tend to be more messy than a standard incline conveyor, FEECO utilizes custom-designed inlet hoppers to maximize loading capacity for straight inclines while keeping loading points clean. And while steep incline conveyors cannot utilize the belt cleaners that standard incline conveyors can, enclosures are available to minimize fugitive material. Belt thumpers, which shake material off the belt, are also available for steep inclines. Additionally, a drag chain conveyor can be included under the steep incline in order to capture fugitive material and introduce it back into the material stream or capture it in a collection hopper.

Capacity

Although the available belt widths for the two types of conveyors are the same (18-72”), steep incline conveyors have a slightly lower capacity than standard incline conveyors. This reduced capacity is because the sidewalls on the steep incline belt take up a portion of the belt width, making the “effective width,” or the width inside the sidewalls, slightly less.

Physical & Structural Differences Between Incline Conveyors and Steep Incline Conveyors

The operational differences in these two types of conveyors necessitate different physical and structural requirements for each type as well. These differences are most apparent in the conveyor belting and the structural framing.

Conveyor Belting

Incline conveyors use smooth belting. Cleated or chevron belting can be employed to contain material and prevent fallback if necessary. This type of belting is generally effective for angles up to 30° depending on the characteristics of the material being conveyed.

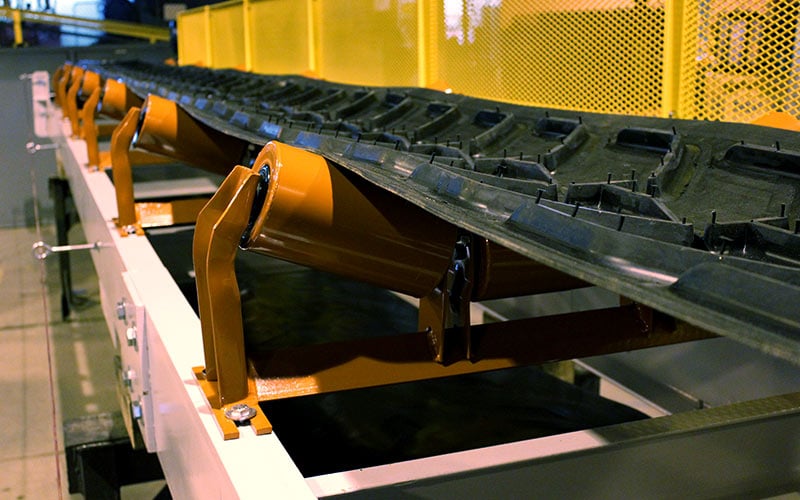

FEECO Incline Conveyor with cleated belting

Steep incline conveyors running at angles exceeding 30° will require a different type of cleated belting known as pocket or corrugated sidewall belting.

Pocket or sidewall belting forms “pockets” or troughs at intervals along the conveyor in order to contain material at steep angles.

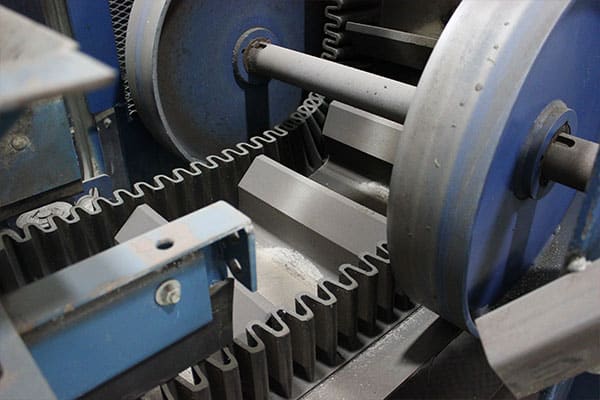

FEECO Steep Incline Conveyor with pocket/sidewall belting

Conveyor Frame

The difference in structure requires a different frame design; while troughed incline conveyors can use a channel stringer or structural truss type of frame, steep incline conveyors only use the channel stringer type.

The table below summarizes the main differences between incline conveyors and steep incline conveyors:

| Incline Conveyors | Steep Incline Conveyors | |

| Key Differentiators | ||

| Angle of Transport | Up to 18° | 18° -90° |

| Spatial Footprint | Greater (length to rise requirements) | Significantly less |

| Transfer Points | Greater when using multiple handling components | Fewer, as it replaces multiple components |

| Capacity | Greater | Slightly less (“effective width” of belt is slightly reduced) |

| Physical & Structural Differences | ||

| Belting | Standard smooth belting, with cleated belting available | Cleated belting with corrugated sidewall/pocket belting available |

| Frame | Truss or channel frame | Channel frame only |

Choosing Between Inclined and Steep Inclined Conveyors

It’s important to recognize that neither type of conveyor is necessarily better than the other; whether or not one is a fit over the other is dependent on the specific parameters of the situation. Most often, this comes down to the allotted spatial footprint in the plant.

In facilities where spatial limitations exist, the steep incline conveyor offers a better handling option. However, if space is not a concern, an inclined troughed belt conveyor can achieve a greater capacity and promote a cleaner production environment.

As other factors such as transfer points and fugitive material come into play, bulk solids handling experts such as those at FEECO International are often helpful in selecting the most beneficial solution.

Conclusion

Incline and steep incline conveyors both offer a reliable handling solution for bulk solids. While the primary difference between the two types of conveyors is the angle at which they transport material, several other considerations such as spatial footprint, capacity, and more come into play as well. The decision on which conveyor suits a given job best may require the help of a bulk solids handling expert.

FEECO has been providing customized bulk solids handling solutions to an array of industries, from fertilizer and chemicals, to minerals and ores since 1951. In addition to helping you make the best decision for your handling application, we can provide everything from a single piece of handling equipment, to a complete handling system with controls, and even parts and service support. For more information on our custom conveyors, contact us today!