As industries pursue cleaner operations and greater efficiency, many producers are asking whether their rotary kilns (and in some cases, dryers) should be powered by electricity instead of traditional fuels such as natural gas, oil, or diesel.

While electrification offers compelling advantages, it also presents notable challenges. Choosing the right approach requires balancing energy goals, operating costs, and process demands.

A Note on Electric Rotary Dryers

It’s important to note that direct rotary dryers cannot run on electricity, because electricity does not produce a carrier gas stream, which is critical to the drying operation. Further, the electricity required to heat the necessary volume of air would also be cost prohibitive.

In order to run on electricity, the dryer would instead need to be converted to the indirect configuration. However, because indirect drying is inherently so much less efficient, the resulting dryer would need to be orders of magnitude larger than a direct-fired unit. Because of this, while rotary kilns can be run on electricity, rotary dryers are almost never powered by electricity.

What are the Advantages of Electric Rotary Kilns?

Electric rotary kilns can offer a number of process advantages:

Reduced Emissions

Electric-powered rotary kilns can significantly reduce or even eliminate direct greenhouse gas emissions when paired with renewable electricity sources, making them attractive for companies with aggressive decarbonization or ESG targets.

Reduced Off-Gas Treatment

Because off-gases from combustion are not present, the exhaust gas handling system can be much smaller and simpler, though some treatment will always be required.

Greater Temperature Control

Electric heating systems allow for precise, uniform temperature control compared to combustion-based systems, which can have hot and cold spots. In indirect kilns, temperature profiles can also be tightly controlled along the length of the kiln with an electric system. This facilitates the creation of heat zones for processes that demand exacting thermal profiles—such as catalyst preparation, specialty chemicals, or advanced materials. This precision temperature control can translate into better product quality and consistency.

Simpler Permitting and Operation

In some regions, eliminating on-site combustion can simplify permitting, reduce monitoring requirements, and lower regulatory burdens. Additionally, electric units may require fewer safety considerations related to fuel handling, storage, and combustion systems.

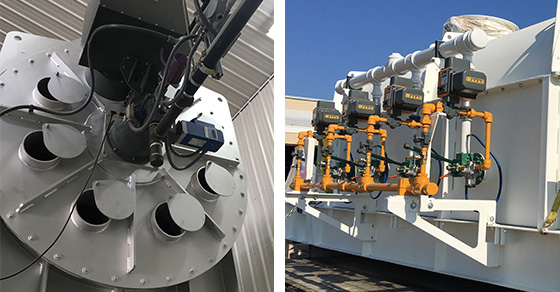

Potential for Lower Maintenance

Without burners, fuel trains, and combustion chambers, electric systems may see fewer maintenance requirements.

Limitations of Electrification

While electric rotary kilns can offer some significant advantages, they are not without challenge. Common issues include:

High Power Demand and Costs

One of the biggest deterrents to electrifying rotary kilns is the high power demand.

Rotary kilns are energy-intensive systems. Electrifying them requires significant power infrastructure, and in many regions, electricity remains more expensive per unit of energy than natural gas or coal. This can greatly increase operating costs unless offset by favorable electricity pricing or renewable energy contracts.

Limited Availability at Large Scale

While smaller and specialty kilns can be adapted to electric heating, scaling up for heavy-duty industrial use presents technical and economic challenges. High-capacity rotary kilns often exceed practical electric load limits with current grid infrastructure.

For the same reasons, it may not be feasible to reach the desired temperature in higher-temperature kilns (above 1000° C); the amount of continuous power required is simply not practical.

Dependency on Grid Stability

Reliability of energy supply is critical for continuous processing. In areas where the grid is unstable, power outages or fluctuations can pose risks to production. Backup systems may be required, adding to costs and complexity.

Retrofit Challenges

Converting an existing fuel-fired system to electric power may require extensive modifications. The design of the shell, refractory, and drive system may need to be re-engineered to accommodate different heat transfer mechanisms. In many cases, a retrofit may exceed the cost of a new unit.

The Case for Traditional Fuels

Despite growing interest in electrification, traditional fuel-fired systems still dominate large-scale thermal processing. Most rotary kilns, except in some small or specialty settings, run on diesel, fuel oil, or natural gas/propane.

The benefits of traditional fuel-based systems include:

- Energy Density and Cost: Traditional fuels provide a high thermal output at a comparatively low cost.

- Infrastructure Readiness: Fuel systems are widely supported by existing infrastructure and operational experience.

- Scalability: Fuel-fired units can be engineered to meet virtually any size or capacity requirement, making them indispensable in high-throughput industries.

Atmosphere Control: Many processes rely on the oxidizing or reducing gases created by fuel combustion. Electricity alone cannot provide this.

Striking the Right Balance

For many applications, hybrid or transitional approaches may emerge. For example, producers might install electric kilns for specialty, high-value materials while continuing to rely on fuel-fired systems for bulk commodities. In other cases, supplemental electric heating may be used alongside combustion to improve precision or reduce emissions.

Frequently Asked Questions (FAQs) Around Rotary Kiln Electrification

Can rotary kilns run entirely on electricity?

Yes, this is possible with small- to medium-sized units. Large-scale applications are not practical to run on electricity alone.

Can I convert my existing rotary kiln from combustion to electric?

Yes, but it will be costly. It may even be better to buy an entirely new system.

What are the biggest benefits of an electric rotary kiln?

- Lower or eliminated emissions

- More precise temperature control

- Potentially lower maintenance due to lack of burners and fuel systems

- Reduced requirement for off-gas treatment

- Easier permitting in some regions (due to a lack of combustion exhaust)

What are the down sides to electric rotary kilns?

- High power requirements and associated costs

- Reliance on grid, especially in locales with less infrastructure

- Limitations on scale and temperature

How do operating costs compare between traditionally fueled and electric rotary kilns?

Unless the site has access to low-cost or renewable electricity sources, electric units tend to cost more to operate. Fuel-fired units are hard to compete with economically, and particularly at large scales, especially when the fuel source is low cost and readily available.

How do I decide which fuel source is right for my plant?

The decision comes down to unit capacity and temperature, as well as balancing availability and cost of fuel sources. Those who are unsure should work with a qualified rotary kiln manufacturer to make the best decision for their specific application.

Conclusion

While electrification offers clear benefits, challenges in power demand, scalability, and economics mean traditional fuel-fired systems continue to play a central role in most industrial operations. Whether to choose an electric or fuel-fired rotary kiln depends on balancing sustainability goals, process requirements, operating costs, and available infrastructure.

For producers considering new equipment or retrofits, evaluating both short- and long-term factors—energy costs, regulatory drivers, and process needs—will be critical in making the right decision. To speak with a FEECO expert about your rotary kiln fuel system, contact us today!