The pyrolysis kiln looks to be an effective approach in recycling black mass – the powdery mixture of key battery minerals remaining after mechanical reduction of spent lithium-ion batteries (LIBs) – as the increasing adoption of LIBs in everything from cellphones to electric vehicles has led to a growing need for improved battery recycling solutions.

Finding an effective, environmentally friendly approach to recycling black mass is fundamental to promoting a circular economy and properly managing resources in the face of this ongoing growth.

3D Rendering of a FEECO indirect-fired pyrolysis kiln

The Need for Black Mass Recycling

The need for lithium-ion batteries, as well as critical minerals, is expanding by the day as technology continues to permeate every aspect of our lives and the world moves toward a clean energy future. One recent report predicted that the LIB market will see a CAGR of 20.3% from 2024 to 2030.[1]

While unusable in their existing form, recycling allows for the recovery of a number of valuable components from spent LIBs. Black mass is produced when these batteries are disassembled, shredded, and ground, yielding a powdery substance rich in critical minerals and battery chemicals. The recoverable materials differ depending on the specific chemistry of the battery and may include:

- Graphite

- Carbon black

- Cobalt

- Copper

- Nickel

- Manganese

- Lithium carbonate

- Lithium hydroxide

The importance of recovering these materials is three-fold:

It Prevents Environmental Hazards

The components contained within spent LIBs, while valuable, present a number of environmental risks, including soil and groundwater contamination, if not properly managed. Recovering these components keeps them out of the ecosystem, protecting human, animal, and plant life for future generations.

It Promotes a Circular Economy

As with any critical resource, the ability to capture and reuse the materials contained within spent LIBs promotes a circular economy, fostering a more sustainable and efficient approach to resource use.

It Relieves Pressure on Virgin Resources

Recovering the valuable components contained within spent LIBs not only averts environmental risks and encourages more sustainable resource use, but also reduces the need to source virgin materials, of which the world is in dire immediate need.

The ability to supplement virgin materials with recycled ones reduces pressure on finite resources and helps to alleviate some of the challenges associated with mining and refining these materials.

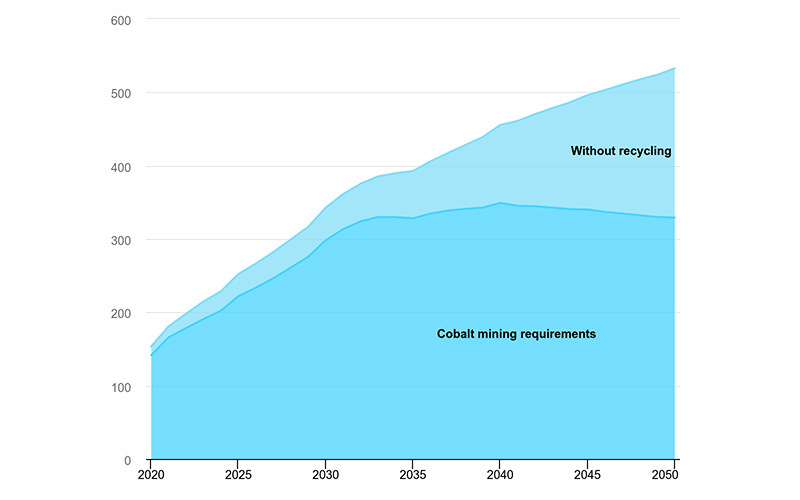

In their report, Recycling of Critical Minerals, the International Energy Agency (IEA) found that by successfully scaling up recycling, “new mining activity could be reduced by 25-40% by 2050 in a scenario that meets climate pledges.”[2]

The chart below from the IEA report illustrates this concept with cobalt.

IEA (2024), Cobalt: mining requirements in the Announced Pledges Scenario, 2020-2050, IEA, Paris https://www.iea.org/data-and-statistics/charts/cobalt-mining-requirements-in-the-announced-pledges-scenario-2020-2050, Licence: CC BY 4.0

Further, emissions that would otherwise be associated with mining virgin resources would also be eliminated.

The factors explained here have culminated into a burgeoning industry around recycling these valuable components, primarily in the form of black mass. As such, the market for recycling black mass is expected to grow significantly, with some experts anticipating a 17.3% CAGR from 2024 to 2032, landing on a market valuation of USD 51.70 billion.[3]

Pyrolysis is a type of thermal treatment in which target components can be isolated via chemical reaction according to specific temperature profiles. The pyrolysis of black mass is generally carried out at temperatures ranging from 600° to 850° C, which facilitates the breakdown of organic components, allowing for full recovery of metallic and carbonaceous materials.

While hydrometallurgical and mechanical means of recycling LIBs offer alternative options, pyrolysis offers a unique opportunity thanks to several advantages.

As with plastics pyrolysis, the use of a rotary kiln to pyrolyze black mass is favorable because of its ability to accept a wide range of feedstock and material mixtures; the acceptance of contaminants such as polymer binders and electrolytes means less upfront pretreatment to recover valuable components.

Compared to hydrometallurgical methods, pyrolysis also minimizes secondary waste generation, requires fewer chemical inputs, and operates at a lower overall cost. It can also add value to the operation by producing secondary products such as syngas and pyrolytic oil, which have applications in energy recovery.

Pyrolysis in a Rotary Kiln

Rotary kilns are widely utilized for conducting pyrolysis due to their flexibility in feedstock acceptance, as well as their scalability, effectiveness, and durability.

Based on proven rotary drum technology, the heavy-duty build typical of rotary kilns is an ideal fit for the rigorous processing requirements of black mass pyrolysis, offering consistent, reliable production in a demanding industry.

Kiln design for black mass recycling applications centers around several key aspects:

Indirect Kiln Configuration

Black mass pyrolysis is carried out in an indirect kiln in order to reduce potential contaminants associated with the off-gasses. Indirect kilns are also favored when the components to recover are especially high value (e.g., cobalt or nickel), as the indirect approach again reduces potential for contamination of the output.

Indirect kilns are heated externally, either with natural gas and burners or electricity. They often employ an inert, oxygen-deprived environment, which prevents combustion and oxidation of the material.

FEECO Indirect Kiln

Retention (Residence) Time

Retention or residence time is unique to each operation, with battery chemistry and desired output dictating the specific time and temperature profiles necessary.

Materials of Construction

The corrosive nature of battery chemicals, paired with the abrasive quality of black mass, requires special attention to materials of construction; materials must be chosen carefully to minimize wear and maximize longevity.

Cooling

While primary focus is on the thermal treatment of black mass, cooling after pyrolysis is also important to consider. The use of a rotary cooler after the kiln reduces material temperature for further safe handling and prevents the material from re-oxidizing, where applicable.

Conclusion

Black mass recycling through pyrolysis in indirect rotary kilns represents a sustainable, efficient, and economically viable solution to the challenges posed by spent LIBs. By addressing key operational and design considerations, the pyrolysis process not only maximizes material recovery but also contributes to the broader goals of environmental sustainability and resource conservation. As the demand for LIBs continues to grow, rotary kiln operations will play a crucial role in the future of battery recycling.

FEECO is the leading manufacturer of custom pyrolysis kilns. From engineering to parts and service support, our rotary kilns are backed by more than 75 years of experience. For more information, contact us today!

SOURCES:

- Grand View Research. Lithium-Ion Battery Market Size, Share & Trends Analysis Report. Grand View Research, n.d. https://www.grandviewresearch.com/industry-analysis/lithium-ion-battery-market.

- International Energy Agency. Recycling of Critical Minerals: Executive Summary. International Energy Agency, n.d. https://www.iea.org/reports/recycling-of-critical-minerals/executive-summary.

- Black Mass Recycling Market by Source, Technology and Region—Global Forecast. MarketsandMarkets, n.d. https://www.marketsandmarkets.com/Market-Reports/black-mass-recycling-market-114706852.html.