In fertilizer, mineral processing, and other heavy industries, equipment downtime can mean lost production, missed contracts, and extensive recovery efforts, all of which translate into higher costs and risk. And while strategies are often the focus of maintenance and reliability managers, the ability to keep plants running also depends on a well-managed spare parts inventory.

Done right, inventory management has the power to minimize downtime, reduce costs, and improve reliability. Done poorly, it can lead to overstocked storerooms, capital tied up in unused parts, or worse: line stoppages when a critical component isn’t available.

Whether just starting out an inventory management program, or looking to improve an existing system, consider these fundamental aspects to optimize parts inventory and minimize unnecessary downtime and costs.

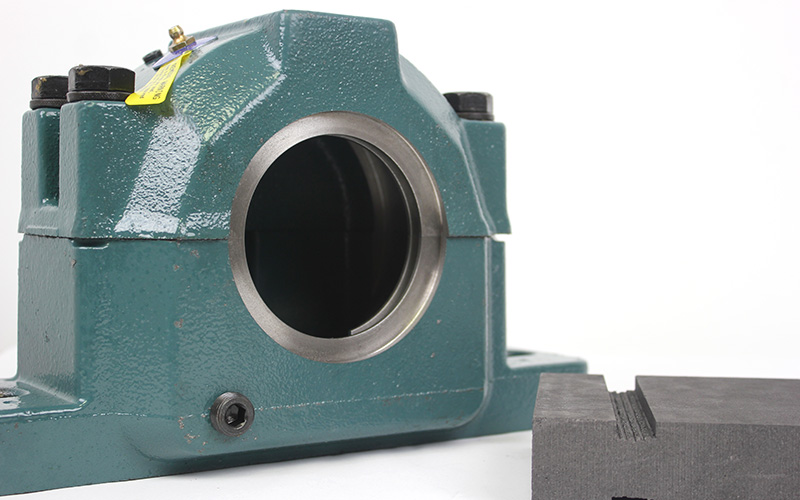

Replacement trunnion bearing and graphite lubrication block

Define Criticality & Risk

The first step in managing a parts inventory program starts with prioritizing components based on criticality and risk. Assess which parts should be designated as critical. Typically wear-critical parts are defined as those that the equipment cannot or should not operate without. Depending on the OEM, these parts may already be indicated as critical in the spare parts list provided in the equipment manual.

Categorizing parts based on how critical to the operation they are and the level of risk they represent is the first step in prioritizing which parts should be kept on hand versus those that can be ordered as needed.

Prioritization should also take the plant’s unique operating conditions into consideration as well. If the plant is processing a particularly corrosive material, for example, wear parts such as pin mixer pins or chute liners are likely to have a shorter service life, making it worthwhile to keep a higher quantity of spares on hand.

Balance Cost and Availability

Criticality and risk must be carefully balanced against cost and availability. While carrying too much inventory ties up capital, stocking too few parts can make the plant subject to volatile pricing, inconsistent availability, or long lead times.

For parts that have the potential to incur significant downtime if a spare is not readily available, set reorder points and keep a safety stock to prevent long delays; emergency part orders and rush shipping can incur additional fees that far exceed the cost of standard procurement. Techniques like ABC classification (based on value and importance) or risk-based criticality matrices can help to determine the right balance between risk and investment.

A trunnion wheel, for example, is a high-cost component, leading many to avoid stocking a spare to save on costs. However, since a rotary drum cannot operate without all of its trunnion rollers, if one were to fail, the production line could be down for anywhere from 10 to 14 weeks waiting on a replacement, making a spare well worth the investment.

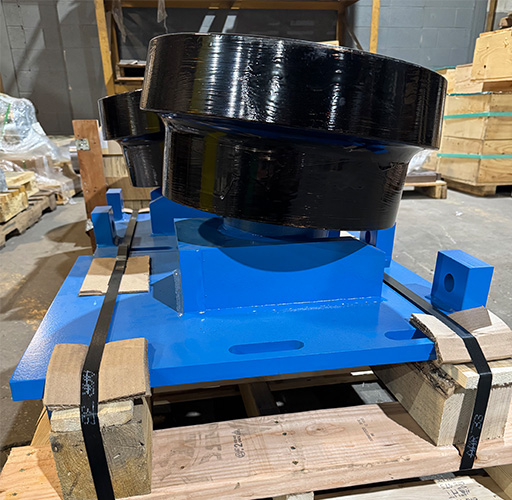

Spare trunnion wheel bearing assembly prepared for shipment

Further, while the OEM may keep some parts on hand, other components may be a custom size or manufactured custom for the equipment, requiring extensive lead time to procure.

Align Your Parts Inventory With Your Maintenance Strategy

Anticipate part needs according to expected maintenance. Where possible, schedule maintenance procedures for planned shutdowns and slow production periods, stocking rebuild kits and consumables according to anticipated needs.

For example, if the plant’s rotary dryer is planned to undergo tire reshimming at the next outage, a shim kit should be ordered well in advance to avoid delays.

Outages, planned or unplanned, are also a good time to review inventory.

If using predictive or condition-based monitoring, data from sensors can also help to forecast potential failures, allowing for inventory adjustment as needed.

FEECO recommends having the OEM or other qualified service provider conduct annual inspections on capital equipment for a more thorough evaluation of the equipment’s mechanical condition. This will help in forecasting future maintenance requirements, including parts that will need to be replaced.

A FEECO Customer Service Engineer inspects a rotary dryer

Leverage Historical Data

Keep detailed maintenance records and conduct analyses to understand past failure trends and usage patterns. This data can be crucial for forecasting future demands and preventing stockouts.

Implement & Maintain Thorough Documentation

Thorough and accurate documentation is essential to proper inventory management. Many parts inventories often start out in proper order, but fall to disorganization as components are taken out of stock without documentation.

A lack of clear documentation causes confusion around which parts are available on site, resulting in wasted time searching for parts and updating records.

Options in documentation range from simple excel files to sophisticated parts management software. Manual documentation requires all personnel to be diligent in their data entry, but can be an effective, low-cost approach to management when carried out properly. Software programs and apps can automate much of the inventory management process but are often costly.

Utilize all tools at the plant’s disposal. FEECO recently developed a system designed to streamline parts inventory management for FEECO equipment owners. The customer scans a QR code affixed to the equipment and is taken to their exact spare parts list. From there, customers can browse the list and put together a quotation request that is immediately delivered to the FEECO Parts Team. Customers can also make service quote requests through the system.

In addition to utilizing all available tools, follow general best practices to maintain organization and recordkeeping. This might include:

- Standardized naming conventions

- Barcoding or RFID systems for real-time tracking

- Regular audits to remove obsolete parts or excess stock from retired equipment

- Proper labeling

Maintenance managers and personnel should also have a workflow in place to integrate new equipment or upgraded parts into the existing inventory.

Choose OEM Parts Where it Makes Sense

Stocking spare parts is ineffective if they are not the right parts. While use of aftermarket parts is acceptable in some settings, only OEM parts are guaranteed to fit and function as an exact match. OEMs also stand behind their products, so if a part is faulty or operating conditions have changed, they can help to find the best substitute as quickly as possible.

Spare thrust roller assembly ready for shipment

Leverage Partnerships

One of the most effective ways to build and maintain a solid parts inventory program is to form partnerships with reliable vendors. A solid understanding of your unique equipment and operating conditions can help vendors advise on managing inventory as efficiently as possible.

These partnerships may also be able to offer support when situations arise, locating and expediting the necessary parts to assist.

Order Start-up Spares Early

A preventable, but all-too-common problem the FEECO Customer Service Team encounters in the field is the delay of startup because the right spares are not on hand.

FEECO recommends a number of start-up spares be ordered prior to commissioning. While ideally all components will fit and function properly and no mistakes will be made, it is not uncommon to see a defective part or parts damaged due to user error during the install process.

Spare belts, couplings and hubs, as well as bearings, should be on-site prior to start-up; if the recommended start-up spares are not readily available and something goes wrong, the start-up process will be forced to be put on hold.

Conclusion

Managing a spare parts inventory isn’t just about filling shelves — it’s about building resilience into operations. By defining criticality, aligning stocking decisions with maintenance strategies, keeping accurate documentation, and working with trusted partners, facilities can avoid the costly consequences of downtime while making the most of their capital.

With decades of experience in designing, building, and servicing rotary drums, bucket elevators, and other process equipment, FEECO has seen firsthand the difference a well-managed spare parts program makes. For many plants, it’s not just a best practice — it’s a competitive advantage.

FEECO has been assisting customers with assessing and replacing parts on both FEECO and non-FEECO equipment for decades. We can not only guide you in selecting the right parts for your operation, but we can also help you to build an inventory program tailored to your needs. For more information, contact us today!