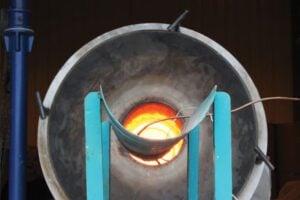

Calcination Brings Desired Qualities to Diatomaceous Earth

Diatomaceous earth, also known as diatomite or kieselguhr, is an industrial mineral essential to everything from producing beer and wine, to extending and whitening plastics. The diverse application of diatomaceous earth demands great variation in the material as a feedstock, and producing the different qualities …