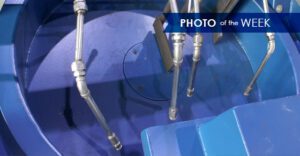

Photo of the Week: Material Processed in a Pug Mill

This week’s photo highlights material processed in a pugmill mixer. Pug mills, also known as paddle mixers, are industrial mixers used to condition, mix and agglomerate materials often in the presence of a binder. The pugmill mixer’s dual shafts with pitched paddles create a kneading …