Heavy-duty bulk material handling equipment plays an essential role in transporting and conveying phosphates in settings ranging from initial mining, to the production and shipment of fertilizers and animal feed products.

The following covers the key types of equipment used in these settings, as well as considerations important to keep in mind when handling phosphate materials.

Common Phosphate Material Handling Equipment

Bucket Elevators

Bucket elevators transfer phosphate materials vertically and are often chosen because they are ideal for high-capacity handling applications.

While single chain bucket elevators are an option, the most popular choice for phosphate bucket elevators is the double chain continuous style, due to its increased capacities and height capabilities.

Bucket elevators are highly customizable, allowing for an optimal handling solution to be met for nearly any application.

Trough Belt Conveyors

Trough belt conveyors are also commonly used in phosphate processing operations. Belt conveyors allow material to be carried horizontally and are commonly used to transport material from one process stop to the next, or from one building to another.

Belt conveyors are also extremely customizable, with common modifications including the addition of loading skirtboards, belt cleaning systems, and more.

A variety of additional conveyor types exist to further optimize the handling of a given phosphate operation, with two of the most popular being:

Reversing Shuttle Conveyors

A reversing shuttle conveyor consists of a trough belt conveyor that is mounted to a rail or track system, in order to allow for more than one discharge point and conveying in both directions.

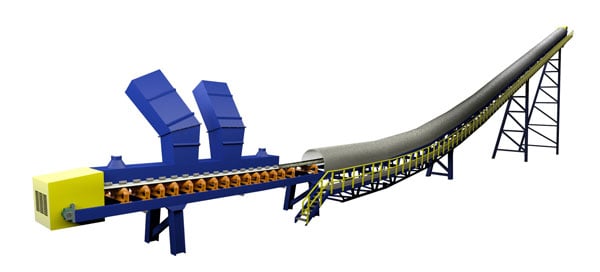

Steep Incline Conveyors

Steep incline conveyors carry material vertically, or at an angle that is too steep for horizontal transport.

Belt Trippers & Plows

Belt trippers and plows allow for increased flexibility of a trough conveyor. Trippers travel along the length of the conveyor and can discharge material at any point along the travel range, providing for a continuous, long storage pile of material, as compared to a single pile of material discharged from the end of a conveyor. Trippers essentially “trip” material off the conveyor at either fixed or movable points, while belt plows are fixed, but allow for discharge from the conveyor on one or both sides.

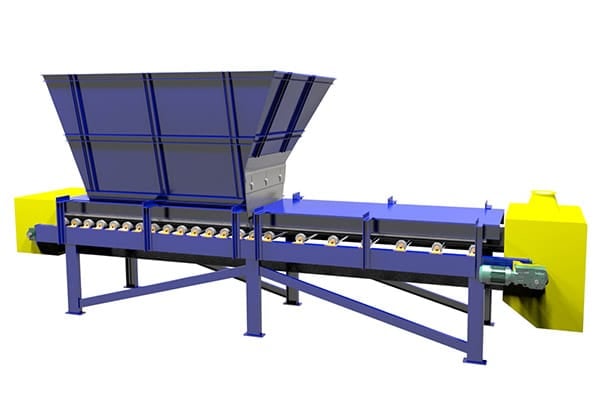

Belt Feeders

Belt feeders ensure a controlled feed rate from a bin or hopper onto a conveyor or other piece of process equipment. They are highly versatile and can be used in a variety of applications.

Considerations in Handling Phosphates

Whether the material is animal feed, fertilizer, or phosphate rock, phosphate products present a few challenges that will require ingenuity on the part of the equipment manufacturer…

Abrasion & Corrosion

Phosphates are often abrasive and sometimes corrosive. Material handling equipment is likely to require customizations to guard against abrasion and corrosion in order to maintain process efficiency and prolong equipment life.

This might include reinforcing high-wear areas such as transfer chutes, or using various alloys such as stainless steel to construct the handling equipment.

Build-up

Additionally, material should not be allowed to build up in equipment, as this can promote excessive wear. Here again, materials of construction, as well as fabrication techniques, play an important part in minimizing the potential for build-up to occur.

Conclusion

No matter what type of phosphate operation is at hand, material handling equipment plays a critical role in automating the process and allowing for flexible, seamless operation. FEECO has been providing custom material handling equipment since 1951 and has been serving the needs of the phosphate industry for just as long. For more information on our heavy-duty phosphate material handling equipment, contact us today!