Bucket elevators are a critical component in many bulk material handling processes, designed to move materials vertically with efficiency and reliability. To ensure optimal performance, reduce downtime, and extend the life of this equipment, it’s essential for operators to follow specific best practices. From maintaining correct tension in belts or chains to adhering to manufacturer guidelines, these practices not only keep the elevator running smoothly but also enhance safety in the work environment. In this article, we will explore some of the most important operational tips that operators should implement for the effective and safe operation of bucket elevators.

Monitor Belt or Chain Tension

Maintaining the correct tension in the belt or chain is vital for smooth bucket elevator operation. Loose tension can lead to slippage, inefficient material handling, and premature wear, while excessive tension can stress components and lead to breakdowns. Regularly inspect and adjust tension according to manufacturer guidelines.

Monitor Throat Plate Position

The bucket elevator’s throat plate controls the material discharge path, affecting the flow and ideally, minimizing recirculation. Misaligned or poorly adjusted throat plates can result in material buildup, inefficient discharge, or damage to the buckets. Regularly observe material discharge and make adjustments as needed to promote uniform material flow from the elevator.

A bucket discharges into the throat plate/discharge chute

Don’t Overload Buckets

Overloading of buckets is perhaps one of the most common issues seen in elevators, with the desire to increase bucket elevator capacity often leading to increasing bucket fill.

While bucket fill can be increased in some settings, it often leads to a variety of problems, including material spillage, excessive wear on equipment, and in severe cases, catastrophic failure.

In continuous-style elevators, overloaded buckets also result in the buckets “digging” in the boot, which quickly leads to bucket damage.

Ensure Proper Load Distribution

In addition to not overloading buckets, operators should also periodically confirm that material is evenly distributed across the buckets during loading. Uneven loading can lead to wear on one side of the elevator and may cause an imbalance that affects performance and leads to mechanical problems.

If needed, adjust feed equipment, such as chutes or conveyors, to ensure uniform material distribution into buckets.

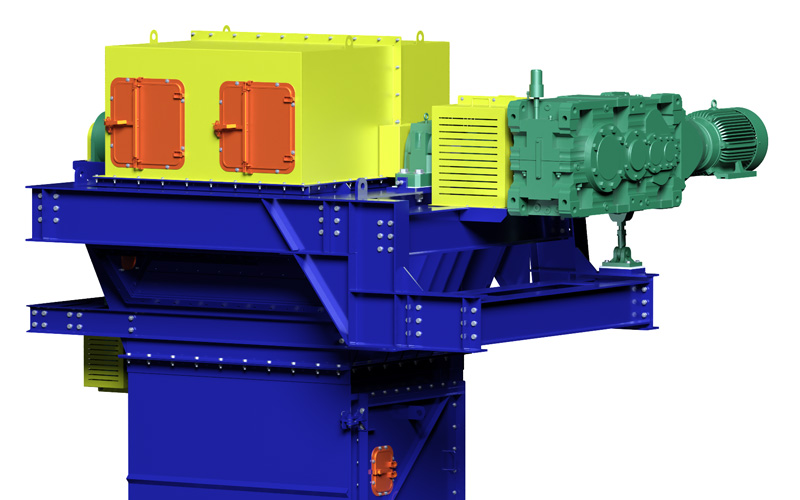

FEECO Bucket Elevator

Maintain Proper Feed Rate

Similarly, it is critical to maintain proper feed rate.

Maintaining a consistent and appropriate feed rate in line with the elevator’s design ensures that the elevator operates efficiently without overloading. Overfeeding can cause material spillage, clogging, or increased wear, while underfeeding reduces efficiency.

Operators should work closely with upstream equipment, such as conveyors or hoppers, to maintain a balanced feed rate.

Regularly Inspect Equipment

Early detection of issues such as frayed belts, worn bearings, or clogged chutes can prevent costly downtime and extend the life of the equipment. As such, operators should implement and follow an inspection schedule, reviewing components such as bearings, belts, chains, pulleys, sprockets, and motor drives. This should include both visual inspections and functional tests to catch potential issues before they escalate.

Operators should observe equipment during regular operation, as well as during shutdowns, looking for visual or auditory cues, as well as temperature abnormalities, that may indicate a problem.

Worn or damaged components should be addressed as quickly as possible to prevent the issue from escalating. For this reason, it is good practice to keep a stock of essential bucket elevator parts on hand for a quick change out. Loose bolts or connections should be tightened immediately to avoid downtime.

Ideally, operators will have a bucket elevator inspection checklist detailing daily, weekly, and monthly review procedures. Any inspections or maintenance should always follow proper safety protocols and OEM recommendations. Operators should document all inspections and adjustments.

3D Rendering of a FEECO Self-Supporting, Super-Capacity Bucket Elevator with inspection doors (in orange)

Follow Safety Protocols

Safety should be the top priority when operating bucket elevators. Operators should be trained in proper safety and maintenance procedures, allowing them to operate equipment safely, recognize potential issues, and maintain a safe working environment.

Clear protocols for lockout/tagout procedures, emergency stops, and handling potential blockages or breakdowns are essential. Proper guarding of all moving parts should also be ensured to protect workers from injury.

Regularly review safety protocols with the entire team and update documentation and procedures as needed to reflect changes in equipment or operating conditions.

Start with an Empty System

To protect the equipment and ensure a smooth start-up, always begin with an empty bucket elevator. Starting with a full or partially loaded system puts excessive strain on the motor and belts or chains, which could lead to failures or reduced efficiency.

Operators should also check the boot section for material buildup prior to starting the equipment, clearing any blockages to ensure a smooth startup and minimal mechanical stress. Once the system reaches full operational speed, gradual introduction of the material can begin.

In cases where an unexpected shutdown has left buckets loaded, a backstop can help prevent back-spooling—a dangerous condition where loaded buckets cause the elevator to rotate backward uncontrollably. If the backstop is in place and functioning, the unit can be safely restarted, though the operator should be prepared for some fully loaded buckets to discharge immediately.

By following these guidelines, operators can avoid startup stresses and contribute to the longevity and reliability of the bucket elevator.

Follow Proper Start-Up and Shutdown Procedures

Operators should always adhere to recommended start-up and shutdown procedures. This ensures that the system runs smoothly and avoids unnecessary strain on the components.

In addition to starting the equipment empty as recommended, operators should allow the elevator to fully discharge before stopping the system for shutdown.

Keep the Work Area Clean

A clean workspace is critical to maintaining safety and preventing accidents. Material spillage, loose components, or tools around the base of the bucket elevator can pose hazards to both the operator and the equipment.

Always clean up any material spills or debris immediately and regularly sweep around the bucket elevator to prevent safety risks or damage to equipment.

Stay Within Manufacturer Guidelines

Operators should always refer to and follow the manufacturer’s recommendations for operating parameters, such as speed, load capacity, and lubrication intervals. Deviating from these guidelines can result in premature equipment failure or safety risks.

The operating manual should remain readily accessible to ensure that all operators are familiar with the specifications and limits of the bucket elevator.

Report Issues Immediately

Any abnormal behavior or suspected issues should be reported to maintenance teams or plant managers immediately. Delaying repairs or adjustments can exacerbate problems and result in costly downtime.

Operators and maintenance personnel should have an open line of communication with each other, along with clear reporting procedures.

Conclusion

Proper bucket elevator operation goes far beyond initiating start-ups and shutdowns. By following key practices such as maintaining proper belt or chain tension, ensuring load distribution, and adhering to safety protocols, operators can significantly reduce the risk of equipment failure and enhance overall performance. Regular inspections, attention to proper startup and shutdown procedures, and maintaining a clean work area further contribute to the longevity and safe operation of the equipment.

FEECO manufactures custom bucket elevators designed for optimal performance and longevity. Our customer service team is ready to assist you with everything from inspections to spare parts and repairs. For more information, contact us today!