The choice between continuous and centrifugal bucket elevators is the starting point for bucket elevator design, with implications on each decision that follows.

While both configurations serve the same core function – to carry material vertically – they do so in very different ways, with the choice between them depending on both the material’s characteristics and the goals of the handling process.

Choosing the right style is critical to process efficiency, material integrity, and long-term performance.

This article explores how each type works, what materials they’re best suited for, and what design factors to consider in making the right selection for your application.

Overview: Continuous vs. Centrifugal Bucket Elevators

The differences between continuous and centrifugal elevators can be seen in several aspects of their handling behavior and what they are able to achieve. The following table provides a high-level summary of these differences as explained below.

| Feature | Centrifugal | Continuous |

| Operating Speed | Fast | Slow |

| Capacity | Higher | Lower |

| Loading Method | Scoops directly from hopper/boot | Fed through a chute; some scooping |

| Discharge Method | Centrifugal force | Gravity (overlapping buckets) |

| Material Suitability | Free-flowing, durable, powdered | Fragile, friable, abrasive, inconsistent |

| Drive Type | Belt or chain | Belt or chain |

| Best Applications | Sand, gravel, ore, shipping terminals | Fertilizers, potash, light/fluffy materials |

The Cost of the Wrong Elevator Selection

With both types of elevator serving the same purpose, the differences may seem inconsequential. However, choosing the wrong type can have serious product and process ramifications, ultimately impacting the bottom line and equipment service life. This might include:

- Product Degradation: Using a centrifugal elevator for fragile materials can cause crushing, fines, and dust, resulting in product loss, degradation, and fugitive material.

- Excessive Wear: Running an abrasive material through a fast-moving centrifugal system may accelerate wear on buckets, belts, and head pulleys.

- Reduced Efficiency: Selecting a continuous elevator for a high-throughput application can bottleneck production and raise operating costs.

- Unnecessary Maintenance: Using an elevator outside its optimal range can lead to increased downtime and excessive replacement of components.

Working with an experienced bucket elevator manufacturer can help to avoid these issues by ensuring the design and fabrication match process requirements and material characteristics.

The Centrifugal Bucket Elevator: Built for Speed and Volume

Centrifugal bucket elevators, sometimes also called cascade bucket elevators, are built for high-capacity material transfer at fast speeds. This elevator style is ideal for bulk solids that are free-flowing, durable, and not prone to degradation, such as:

- Sand

- Gravel

- Crushed ore

- Cement clinker

- Other granular industrial materials

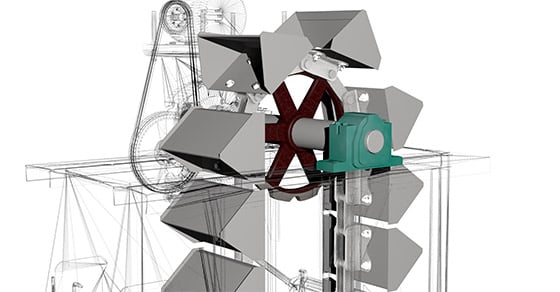

How Centrifugal Bucket Elevators Work

Material is scooped from a boot or hopper as the buckets pass through the bottom of the elevator. Buckets are mounted on a belt or chain and move at a high speed. As they pass over the head pulley, centrifugal force “flings” the material out of the bucket and into the discharge chute.

Because the buckets dig into the material and discharge with force, this system requires durable buckets with reinforced lips, such as the AC-style. The scooping and launching action also means that this style is not suitable for fragile materials, which may degrade under these conditions.

Because of these qualities, centrifugal elevators are typically best suited to facilities requiring high throughput and fast cycling, such as shipping terminals. Care must be taken in matching the belt/chain strength to the applications, with extremely tall elevators facing limitations related to belt stretch and chain tension.

The Continuous Bucket Elevator: Gentle and Controlled Handling

In contrast to centrifugal elevators, continuous-style bucket elevators are designed for gentle handling, making them ideal for sensitive or friable materials. They run at slower speeds, use gravity for discharge, and feature bucket configurations that prevent product damage and minimize dust and attrition.

Common applications include:

- Potash

- Fertilizer blends

- Abrasive minerals

- Light, aeratable powders

- Fragile agglomerates or lumpy feedstock

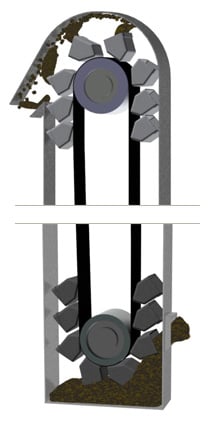

How Continuous Bucket Elevators Work

Material enters the elevator through a feed chute, rather than being scooped. While the buckets may collect some residual material from the boot, the majority of material is gravity-fed into the buckets through the elevated inlet. The buckets are closely spaced and mounted so that as they invert near the head pulley, the material gently slides out and down the back of the preceding bucket, flowing smoothly into the discharge chute.

This discharge method:

- Minimizes degradation

- Prevents aeration of light/fluffy materials

- Reduces dust generation

- Is well suited for inconsistently sized or friable materials

The bucket style in continuous elevators is typically medium front (MF) or similar designs that support gravity discharge and act as part of the discharge chute when inverted.

As with centrifugal elevators, continuous elevators can also use the belt or chain configuration. Their lower operating speeds also tend to promote less wear and a longer service life.

Additional Design Considerations

Maintenance & Operating Costs

The differences in operation have important implications for maintenance and operating costs as well. These are summarized in the table below.

| Factor | Continuous | Centrifugal |

| Wear Rate | Slower wear on buckets and components | Faster wear, especially with abrasive materials |

| Maintenance Frequency | Comparable | Comparable |

| Downtime Risk | Comparable | Comparable, but higher if material is mismatched |

| Component Life | High when properly maintained | High when properly maintained, but reduced for high-impact or abrasive materials |

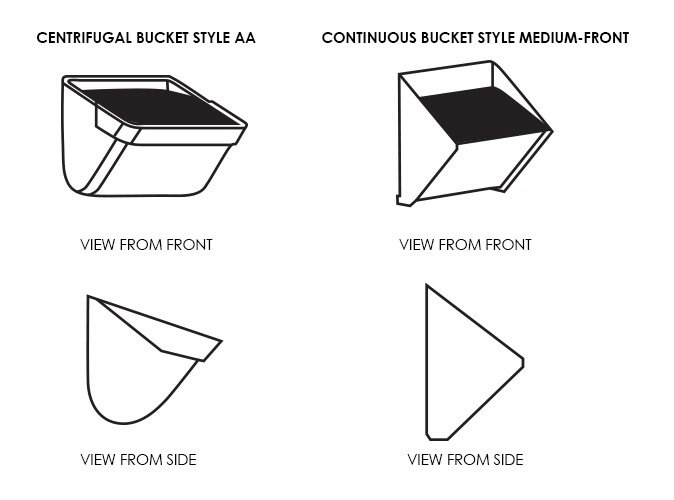

Elevator Bucket Styles

The different feeding and discharge action associated with each elevator type also requires different elevator bucket styles, with specific influences on geometry and construction.

Centrifugal elevators use buckets better suited for scooping and throwing material, while continuous elevators use buckets designed for filling and pouring material. Additionally, continuous style buckets use the back of the leading bucket as a sliding surface to discharge material.

Bucket material (e.g., steel, plastic, nylon) must also be selected based on required wear resistance, impact absorption, temperature, and compatibility with the product being conveyed.

Centrifugal vs. continuous elevator bucket style

Elevator Height & Footprint

The elevator structure is also affected by the chosen configuration.

Centrifugal elevators tend to be more compact for the same capacity but may be constrained by belt stretch or mechanical limits at very tall heights.

Continuous elevators can often exceed the height limitations of centrifugal elevators by using dual chains designed for tension-heavy applications.

Centrifugal vs. Continuous: Selecting the Right Elevator

Choosing between a centrifugal and continuous bucket elevator is not simply a matter of preference—it’s a foundational design decision that impacts every aspect of the elevator’s performance, longevity, and cost of operation. The best choice is determined by evaluating the material characteristics, process requirements, and site constraints together.

To guide this decision, review the following core considerations:

-

- Material Behavior:

- If the material is fragile, friable, or prone to aeration, a continuous elevator is usually the best fit.

- If the material is free-flowing, durable, and not at risk of degradation, a centrifugal elevator is likely more efficient.

- Required Throughput:

- For high-capacity or high-speed operations, such as bulk material loading at terminals, a centrifugal elevator provides the speed and volume needed.

- For applications where gentle handling is prioritized over throughput, such as fertilizer production or mineral processing, a continuous elevator offers better control.

- Wear and Maintenance Tolerance:

- When bucket style is properly matched to the material characteristics, wear between centrifugal and continuous elevators is comparable. However, due to scooping action, centrifugal elevators may experience faster wear when handling abrasive materials.

- Elevator Height and Layout:

- If vertical lift height is a concern, continuous elevators with dual chains may be more suitable, as they better tolerate the tension demands of tall configurations.

- Centrifugal elevators may offer a smaller footprint at lower heights but can be limited in very tall applications due to belt stretch or chain strength.

Keep in mind that a facility may also benefit from utilizing both types of elevator at different points in the process as material characteristics change—for example, using a centrifugal elevator for high-volume intake, while using a continuous elevator later in the process to protect delicate granules.

Ultimately, the right solution is one that aligns with both the material handling goals and the operational realities of the plant. Working with a partner like FEECO ensures the final design accounts for these many variables—not just on paper, but in real-world performance.

Why Work With FEECO?

With over 75 years of experience in engineering, designing, and manufacturing bucket elevators, FEECO brings a depth of process knowledge unmatched by off-the-shelf manufacturers. Where others rely on modular systems, FEECO develops custom-engineered solutions tailored to your specific material and handling requirements.

We also offer extensive parts and service support, helping you keep your elevator running smoothly and prolonging service life. Need help deciding which elevator is right for your material? Contact us today!

- Material Behavior: