What are the Signs it’s Time for Tire Grinding?

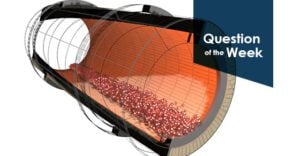

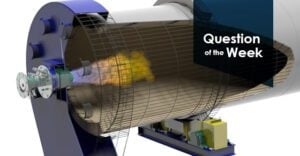

Rotary drum tires and trunnion wheels can become worn over time, and result in the following changes: The characteristics mentioned above can cause the weight of the drum to be unevenly distributed, which in turn, can affect other drum components. Premature equipment failure can then …