From Waste to Resource: The Role of the Pyrolysis Kiln in Black Mass Recycling

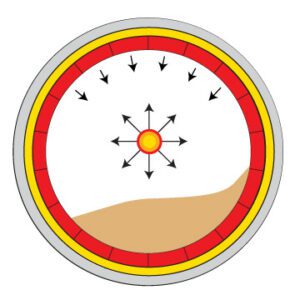

The pyrolysis kiln looks to be an effective approach in recycling black mass – the powdery mixture of key battery minerals remaining after mechanical reduction of spent lithium-ion batteries (LIBs) – as the increasing adoption of LIBs in everything from cellphones to electric vehicles has …