EQUIPMENT

Sometimes also called syn coal, biocoal is a synthetic form of coal that is garnering attention world-wide as nations look for cleaner energy options. This man-made coal product rivals natural coal, because it does not contain sulfur, nitrogen oxides, or mercury. Furthermore, it offers a reduced ash content. All of this results in a cleaner burn and ultimately, fewer greenhouse gases.

MATERIAL PROCESSING

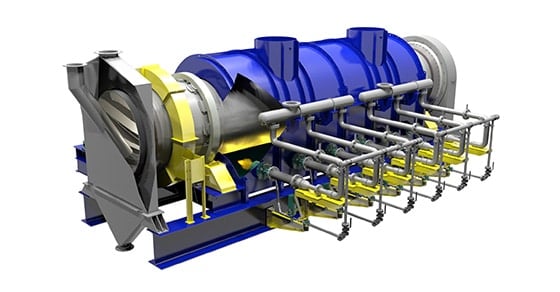

Rotary Kilns

Biocoal is produced through the torrefaction of biomass in a process known as pyrolysis. FEECO offers custom rotary kilns for the production of biocoal from biomass.

BULK MATERIAL HANDLING

FEECO offers a variety of bulk material handling equipment for biocoal. From bucket elevators and steep incline conveyors for vertical transport, to troughed belt conveyors and reversing shuttle conveyors, FEECO offers a wide variety of custom bulk material handling equipment.

FEECO handling equipment can also be equipped with a variety of equipment to increase the flexibility of the system, including belt trippers and plows, as well as belt feeders.

PROCESS TESTING AND DESIGN

The FEECO Innovation Center is a unique testing facility where we can test your material to determine the feasibility of your intended process, as well as define process variables and gather valuable data points necessary for scale-up.

The FEECO Innovation Center is well-equipped to suit a wide range of testing needs, from agglomeration to high temperature thermal processing, as well as continuous process loops integrating multiple testing methods.

We offer comprehensive testing services in four categories:

Feasibility/Proof of Concept: An initial, non-witnessed batch testing phase in which the possibility of creating a product is explored.

Proof of Product: A more in-depth batch testing phase in which more time is spent determining whether a product can be made to desired specifications.

Proof of Process: A continuous testing phase that aims to establish the equipment setup and parameters required for continuous production of your specific material.

Process/Product Optimization: An in-depth study to optimize your specific material’s characteristics and/or production parameters in an industrial setting.

Learn more about the Innovation Center >>

PARTS & SERVICE

FEECO provides a comprehensive offering of parts and service to keep your equipment running its best for years to come. This includes a variety of field services, process and equipment audits, spare parts, and more.

RESOURCES

BIOCOAL ARTICLES

Biocoal from Biomass: An Emerging Opportunity for Renewable Energy

Biocoal, a product produced by thermally upgrading biomass, has been gaining traction throughout the world as countries look to more renewable …

The Thermal Conversion of Biomass to Activated Carbon (And Everything in Between)

The biomass industry has seen steady growth the past few years, as nations around the globe continue to shift focus toward …