Activated carbon is a powerful adsorbent used prolifically throughout water purification efforts to remove contaminants and undesirable components.

While activated carbon can be used in a wide range of water treatment applications, it is a critical tool used throughout municipal and industrial water treatment facilities to treat drinking water, wastewater, and municipal water for process use.

About Activated Carbon

The unique, porous structure and vast surface area of activated carbon, combined with attraction forces, allows activated carbon to capture and hold various types of materials onto its surface.

Activated carbon comes in many forms and varieties. It is produced by processing a carbonaceous material, most often coal, wood, or coconut husks, in a high temperature environment such as a rotary kiln in order to “activate” the carbon and create the highly porous surface structure.

Various forms of activated carbon exist, each offering different material characteristics that make it ideally suited for specific applications. As such, manufacturers offer a wide array of activated carbon products.

Depending on the application, activated carbon may be used in powdered, granular, extruded, or even liquid form. It may be used alone, or combined with different technologies, such as UV disinfection.

Water treatment systems typically employ either granular or powdered activated carbon, with granular activated carbon (GAC) from bituminous coal being the most commonly utilized form.

Water Treatment Facilities: Applications for Activated Carbon

While not overtly obvious, the water we use every day – whether for bathing, drinking, swimming, or otherwise – is frequently brought to us in purified form courtesy of activated carbon.

Drinking Water Treatment Facilities

In drinking water treatment systems, activated carbon helps to ensure that drinking water not only smells and tastes satisfactory, but is also safe for consumption. Drinking water treatment focuses on:

Removal of Contaminants

Activated carbon helps to ensure that water destined for consumption is removed of harmful contaminants such as pesticides, endocrine disruptors, and pharmaceutical products.

Taste and Odor Control

Activated carbon is also employed in reducing components that result in undesirable tastes and odors.

Disinfectant By-Products

Activated carbon has also been more recently utilized in controlling disinfectant by-products, or DBPs at drinking water treatment facilities.

DBPs are formed when the disinfectants used to treat water combine with the natural organic matter (NOM) present in the water to form harmful by-products. Activated carbon has proven to offer an effective approach in removing the precursors (NOM) of disinfectant by-products.

Wastewater Treatment Facilities

Activated carbon is also employed in both municipal and industrial wastewater treatment facilities. The effluent discharged either as municipal wastewater, or the discharge from an industrial process can contain a variety of components that must be removed before they are discharged into waterways or reused.

In these settings, activated carbon helps to protect waterways from contaminants such as pesticides, fuels, and various solvents, to name a few. Here again, activated carbon captures the targeted components for removal, rendering the water sufficient for discharge or its intended reuse application.

Process Water

In addition to dedicated water treatment facilities, many industrial facilities may host their own on-site operation to treat incoming municipal water for use in their specific industrial process. Process water used in the production of beverages, pharmaceutical products, and the like, must often meet highly strict requirements so as not to damage equipment or result in an inferior product.

Process water applications commonly rely on activated carbon to ensure water quality meets the requirements of its intended use.

For all of these water treatment applications, activated carbon can be employed in a number of ways. In each setting, activated carbon may be used alone, or in combination with other treatment methods, such as UV disinfection and/or particulate filtration systems.

Additional Water Treatment Uses

It’s worth noting that while activated carbon is a key component in large-scale water treatment facilities, it can also extend to small-scale and point of use applications as well, such as those listed below.

Aquarium/Pond Filtering

Activated carbon helps to keep aquatic environments free of contaminants that could harm inhabitants.

In-Home Filters

A variety of in-home water filters such as those found in refrigerators, or that can be affixed to faucets, also rely on activated carbon to purify water.

Benefits of Activated Carbon for Water Treatment Systems

The United States EPA recognizes a number of benefits to utilizing granular activated carbon in wastewater treatment, all of which can also be applied to drinking and process water treatment facilities.

Accepts a Wide Range of Materials

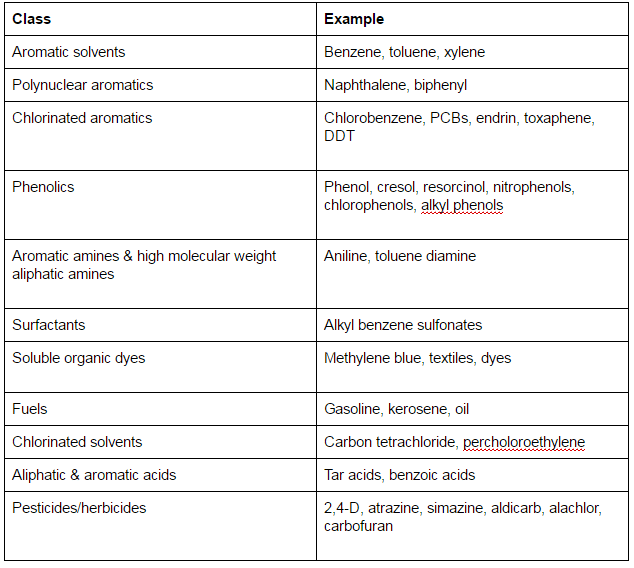

The EPA lists a variety of both organic and inorganic components that can be adsorbed from water by granular activated carbon:

Easy Integration

A GAC system is easily incorporated into existing facility infrastructure.

Small Footprint

GAC systems require only a small footprint, making them a particularly attractive option for facilities with limited space.

Proven in Large-Scale Settings

The EPA recognizes granular activated carbon systems as a proven and reliable approach for removing dissolved organics in high-volume settings.

Cost Savings When Reactivated

Activated carbon can be regenerated, meaning that the “spent” carbon can be processed (typically in a rotary kiln) to be reused; the adsorbed components can be desorbed, and the spent carbon reactivated, allowing it to be reused repeatedly.

Not all activated carbons are reactivated (powdered activated carbon is typically disposed of). However, reactivation is an attractive feature because it costs significantly less than purchasing virgin activated carbon, and also results in a lower carbon footprint; it takes much less energy to reactivate carbon than it does to produce virgin carbon.

Depending on the location and capacity requirements of a treatment facility, on-site reactivation may offer economic benefits. Remote or isolated operations may find that the shipping costs required to transport spent carbon to a commercial reactivation facility will outweigh the cost of an on-site reactivation operation.

Cobb County-Marietta Authority (CCMWA) made headlines last summer for their decision to go with a granular activated carbon filtration system for controlling DBPs in their water treatment process. Among some of the benefits listed above, the county made the decision to go with GAC because it did not produce an excessive amount of wastewater and was a fit for potential future regulations on DBPs. The facility noted that the operational flexibility and maintenance and operation costs of a GAC system were also factors in the decision.

Conclusion

Water is the world’s most valuable resource. As the world’s population grows, the efficient treatment of existing water resources will continue to grow in importance as well. Activated carbon offers an effective solution in many water treatment facilities, whether it’s to ensure drinking water is safe for consumption, to protect waterways from potentially harmful effluent discharge, or to help create products of premium quality.

FEECO offers custom rotary kilns for the production and regeneration of activated carbon, both in and out of the water treatment industry. For more information on our activated carbon rotary kilns, contact us today.