Whether in packaging production, pulp and paper processing, biomass fuel generation or otherwise, wood-based biomass products are handled in a variety of settings and forms, from bark to shredded wood, and perhaps most often, wood chips. The unique characteristics of wood biomass materials require careful consideration in equipment design to achieve seamless material flow with minimal issue.

Outlined here are some of the key aspects to consider in handling wood chips and other wood-based biomass materials in any setting.

Common Wood Chip Handling Equipment

Troughed belt conveyors with weather covers at a pulp and paper facility.

Like most bulk solids, a few key pieces of equipment make up the majority of the equipment used to move wood chips around a processing facility. The most common bulk material handling equipment includes:

Troughed Belt Conveyors

Troughed belt conveyors are the most widely used type of bulk handling equipment when working with wood chips, shredded wood biomass, bark, and the like. These material handling workhorses carry material at grade, or at angles up to 20° (or 30° when cleated/chevron belting is used). Conveyors can be equipped with a wide range of accessories and customizations in order to further tailor equipment to the application at hand.

Troughed belt conveyors offer a number of advantages compared to flat belt conveyors when handling wood products:

Material Protection

The concave profile of the conveyor, created by troughed idlers, helps to keep material on the conveyor and provides some protection from wind or nearby process exhaust. Additional protection can be achieved with weather covers or gallery enclosures.

Material Containment

The troughed belt also helps to keep material contained, eliminating spillage, which is a frequent challenge when handling wood-based materials.

Increased Capacity

The troughed design of the conveyor allows for increased capacities as well. Depending on the manufacturer, troughed belt conveyors may accommodate capacities up to 8,000 TPH.

Wood biomass is conveyed on a FEECO troughed belt conveyor

Common Conveyor Customizations for Handling Wood Chips

Numerous customizations are available in order for handling systems to better work with wood-based materials. Oil-resistant belting, for instance, is recommended to protect conveyor belts against the wood’s natural sap, oil, and moisture content.

Conveyors are also often fitted with magnets or metal detectors in order to prevent foreign objects from entering the boiler and/or hog.

Improving Cleanliness of Handling Wood Chips

The stringy nature of wood chips can be messy, causing loading and spillage issues. For this reason, a number of customizations aimed at containing the material as much as possible are employed.

Skirtboards at load zones minimize fugitive dust, with full-length skirting options available. A slider bed trough that provides a tight seal with the skirtboard can also be implemented to prevent fugitive material from clogging up equipment. Elevated dust settling chambers minimize dusting after the loading zone.

Similarly, belt cleaners and self-cleaning tail pulleys are used to maintain a clean and well-running handling system.

Belt Trippers

Belt trippers are an excellent device in wood chip storage applications, extending the functionality of a belt conveyor. Belt trippers, or “traveling trippers,” can be fixed or movable on the conveyor. The tripper redirects material off of the conveyor at predesignated points, or along the entire length of the conveyor, to be discharged as desired.

In wood handling settings, trippers are frequently used for creating long, linear stock piles of material in both outside and under-roof storage systems.

Belt Plows

Similar to trippers, belt plows promote material discharge from a conveyor at predetermined points, but the points are fixed and ultimately less flexible. When handling wood biomass, belt plows are often used to feed bins or silos with a single-point feed opening.

Belt plow for wood chips

Bucket Elevators

Bucket elevators are another commonly used type of handling equipment when working with wood chips and biomass products; unlike belt conveyors, bucket elevators transport material vertically. Although they are a fit for some wood products, more stringy materials may be better served by other types of equipment.

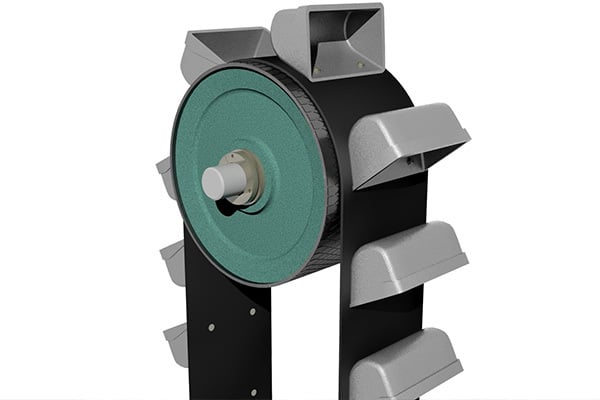

Wood Chip Elevator Design: Centrifugal Belt

While bucket elevators are available in a variety of configurations, centrifugal discharge belt elevators are the configuration of choice when working with wood-based materials. Centrifugal discharge elevators are chosen because they allow for large amounts of material to be moved very quickly.

The belt-type elevator is chosen over the chain-type for a few reasons. The belt design prevents material from otherwise becoming caught up in the chain or getting pinched in the sprocket. The belt design won’t grab the chips like a chain might, and the standard boot pulley in a belt elevator is a self-cleaning wing, allowing chips to be shed as they pass over the pulley.

Design of a FEECO centrifugal discharge belt-style bucket elevator for wood chips

Since wood can be a challenging material to handle, inspection and access doors should be integrated into bucket elevator design to minimize troubleshooting and downtime.

Material Characteristics to Consider in Handling Wood Chips

The unique physical characteristics of the material must be considered in any bulk handling objective, but they can be especially influential when designing a system for handling wood chips and other wood-based biomass materials.

These materials bring unique challenges to the table that will need to be countered with ingenuity in design. In addition to all the typical factors that must be taken into account when designing a bulk solids handling system, special attention should be paid to the following when handling wood-based products:

Moisture content

Depending on the end use of the wood, and the stage of processing it is in, it may hold a higher or lower moisture content. The moisture content should be considered in belt selection; as mentioned, oil-resistant belts should be chosen for high-moisture applications in order to protect the belt from the inherent sap and oil that is characteristic of a high-moisture wood.

Similarly, nylon buckets are a good option for bucket elevators, because they are naturally resistant to moisture.

Flowability

Due to the nature of wood products, they generally exhibit very poor flowability. This can make transfer points difficult and increase the need for belt cleaning systems. Transfer points such as feeders and chutes will need to be designed to minimize friction to prevent material from getting caught up and blocking passages.

Abrasiveness

Wood products can also be quite abrasive. This may require customizations such as abrasion-resistant liners, reinforced high-wear areas, as well as careful bucket selection (here again, nylon is a recommended choice, as it is naturally resistant to abrasion).

Conclusion

Wood-based materials such as wood chips, bark, shredded wood, and more, are an integral part of the energy, pulp and paper, and packaging industries, with a wide variety of roles to fill. The unique characteristics of wood-based biomass materials can make handling such products especially challenging if such characteristics are not factored in to the original design. A variety of configurations and customizations can be used to work with these qualities to create a fluid and efficient handling system.

FEECO is a leader in custom bulk solids handling equipment and systems. Our extensive experience around wood chips and other wood-based materials gives us an unmatched advantage in engineering and fabricating handling equipment that provides superior performance and reliability. For more information on our wood chip conveyors, contact us today!