As with most capital equipment, buying a rotary dryer can be a complex process, especially when it comes to knowing what data rotary dryer manufacturers need in order to provide a quote.

We’ve put together the guidelines below to take some of the guesswork out of gathering initial pricing data and soliciting for rotary dryer bids.

Note: The information provided here assumes that the buyer is looking for a unit tailored to their specific application. Although one-size-fits-all designs are available from many manufacturers, they typically yield a poorly performing dryer. All FEECO rotary dryers are engineered around the specific parameters of the application at hand for optimal performance and longevity.

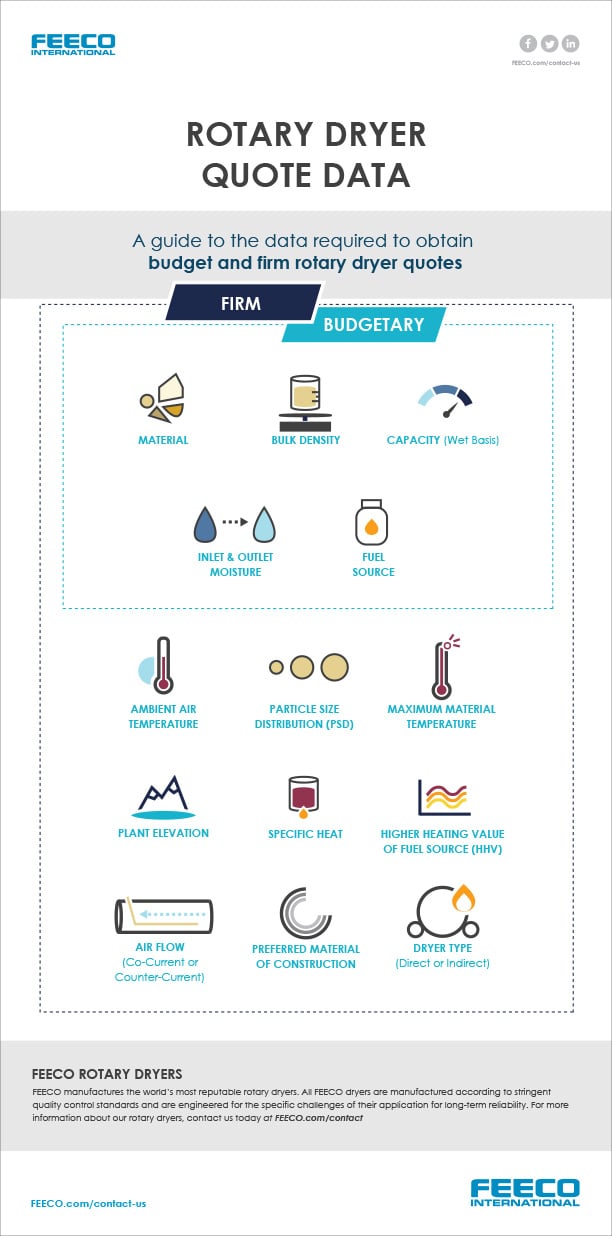

Minimum Data Needed for a Budgetary Rotary Dryer Quote

During the initial stages of a project, many buyers simply want a ballpark estimate of the dryer cost in order to establish rough pricing for decision makers.

The data required for such an estimate may differ based on the vendor, but in general, the following data points are sufficient:

- Material (note that it is best to specify what the material is actually made up of, instead of simply listing a category the material falls under- for example, specifying a material is limestone instead of simply listing the material as aggregate)

- Bulk density

- Capacity (wet basis)

- Inlet and outlet moisture (aka percent moisture in and out) – This data is also important when paired with the raw material as well, because materials hold and release their moisture differently, which can change the design parameters of the dryer. Engineers must be familiar with the specific material to be dried and the challenges that may be presented when trying to achieve the desired reduction in moisture.

It’s important to recognize that not all rotary dryer manufacturers work in the same industries or have the same strengths. In addition to supplying the information needed for a rough budget quote, these data points help manufacturers to determine whether or not the project is a good fit for their capabilities; many manufacturers will only work in certain industries or with specific materials, while others have limitations on equipment size and capacity rates, or may not be capable of working with all fuel types.

Data Needed for a Firm Rotary Dryer Quote

Engineers require a number of additional data points beyond what is given above in order to provide a more firm quote. This typically includes:

-

- Particle size distrubtion (min, max, and avg)

- Maximum material temperature

- Ambient air temperature

- Specific heat

- Plant elevation

- Higher heating value of fuel source

- Preferred material of construction

- Dryer type (direct or indirect)

- Dryer air flow (co-current/parallel flow or counter-current flow) (direct dryers only)

In addition to the basic specifications, this additional information gives engineers a more complete picture of the equipment and project goals, as well as the context in which the dryer will be used. Engineers use all of this information to determine the amount of energy required, drum sizing, retention time, mechanical components, and more.

In some cases, buyers aren’t sure what they need. In these scenarios, FEECO engineers work with the point of contact to evaluate the material and project goals in order to determine the best approach. Additional data and process parameters for scale-up may be gathered through dryer testing in the FEECO Innovation Center.

Conclusion

Knowing what information rotary dryer manufacturers require in order to provide a quote doesn’t have to be a challenge. FEECO utilizes a simple questionnaire to gather both initial and more advanced process and equipment specifications.

FEECO engineers and builds the world’s most reputable rotary dryers – each tailored around its specific application for optimal performance and longevity. For more information on our rotary dryers or the rotary dryer quoting process, contact us today!