Rotary dryers play a crucial role in catalyst manufacturing, where the drying step is essential for ensuring the final product meets precise standards. Though often overlooked, drying significantly influences key properties like uniformity, mechanical strength, and moisture content. This article explores the importance of the drying process, the reasons for using separate drying equipment, and how rotary dryers, with their customizable features, are ideally suited to meet the diverse needs of catalyst producers.

How is Drying Used in Catalyst Manufacturing?

A drying step is necessary after impregnating the catalyst substrate (support) with the active catalyst component. Drying removes the remaining solvent and helps to determine the metal distribution within the support.1

While impregnation was traditionally thought to be the most influential step on the metal profile in catalyst preparation, researchers have found in recent years that the conditions used in the drying step can also have a significant impact.2

Removal of the solvent causes the precursor or active catalytic component to increase in concentration, resulting in precipitation once it reaches supersaturation (precipitation may also occur as a result of dehydration, temperature, or a gas atmosphere). Precipitation can have important implications on the macroscopic distribution of the catalytic component on its substrate.3

What are the Stages of Drying in Catalyst Preparation?

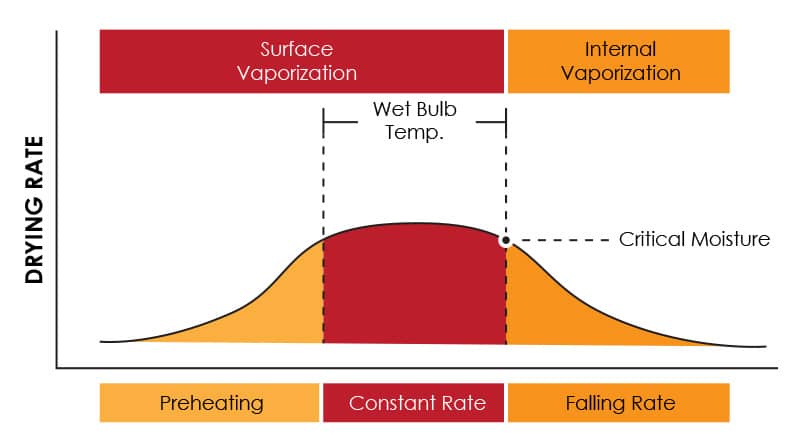

The catalyst drying process is considered in three stages:4

Preheating

Preheating is the first stage of drying in which the support is initially heated. During this stage, drying rate and surface-level liquid vaporization both increase as the temperature rises.

Constant Rate

In the second stage of the drying process, the moisture transport occurring inside the support material keeps the surface saturated, allowing for vapor removal. The drying rate at this stage is dependent upon the rate of heat transfer to the evaporating surface, making surface temperature constant (referred to as the wet-bulb temperature).

Falling Rate

When the material reaches critical moisture content, in which the moisture transport occurring within the support can no longer keep the surface saturated, the drying rate begins to decline. This stage is known as the falling-rate period. During this stage, vaporization begins to occur within the solid.

Simplified illustration showing the different stages of catalyst drying

Why is a dryer required when there’s already a kiln?

The drying step is followed by a calcination step, leaving many to wonder why drying is carried out in a separate unit, instead of within the already-needed rotary kiln.

While this is a valid point, conducting the drying step in the rotary kiln would be extremely inefficient, requiring a very large kiln to accommodate both moisture removal and the required chemical reaction(s). Utilizing separate smaller units is significantly more efficient and less costly.

What Product Parameters are Important in Catalyst Production?

Producers require a precise combination of highly specific chemical and physical parameters unique to the performance requirements of their catalyst. In general, however, the following qualities are always a focus of the drying step:

Uniformity

Catalyst uniformity is of the utmost importance, as these products must be able to meet precise requirements consistently. The level of uniformity required varies from one product to the next. The drying step must promote a uniform product in terms of physical quality and moisture content.

Moisture Content

In order to perform as needed and calcine efficiently, catalyst products must meet specific moisture level requirements. The target moisture content may differ from one product to the next, but as mentioned, should be uniform within the same product.

Attrition

Attrition is the degradation of a granular product into dust and fines. Because catalysts are used in a packed bed reactor where any fines would cause plugging, minimizing the potential for attrition is essential. Some catalyst shapes may be more prone to attrition than others, but when it comes to drying, attrition can result from product degradation.

Product integrity may be compromised during the drying process if the material is exposed to the burner flame, or if overdrying occurs due to higher-than-necessary temperatures or longer retention times. In some settings a low mechanical strength can also encourage attrition.

Attrition tester used for evaluating particles in the FEECO Innovation Center

Mechanical Strength

Two key aspects contribute to a product’s mechanical strength:

Crush Strength

Crush strength is the amount of force, measured in pounds per square inch (lb/in2), required to break a particle.

Crush strength test in progress in the FEECO Innovation Center

Compression Strength

Similar to crush strength, compression strength is designed to assess a material’s strength as a unit under pressure, such as under the weight of a packed bed; measured in Pascals or Newtons/m2, compression strength determines how well a material will hold up collectively under pressure without breaking down.

Mechanical strength is especially important for catalysts that will be continuously circulated between a reactor and regenerator.5

Bulk Density

Bulk density refers to the weight of a material per a specific volume (measured as-is and as tapped density). Materials that have been overdried will have a lighter bulk density than necessary, which could have implications on product handling and performance.

Why Rotary Dryers for Catalyst Preparation?

Rotary dryers have long been the preferred approach to drying in the catalyst industry. While other drying systems are available, rotary dryers can process high throughputs, are extremely heavy-duty, and are widely recognized for their simplicity and long-term reliability. Most beneficial when it comes to catalyst manufacturing, though, is their potential for customization.

The historic lack of understanding around the role of drying in catalyst preparation has meant producers have largely arrived at their processing goals through trial and error, modifying dryers to their specific needs.

Add to that the extremely diverse range of catalyst products, desired parameters, and performance requirements, and extensive customization of the drying step has and continues to be necessary in meeting ever-changing product goals.

FEECO Rotary Dryer

Customizable Rotary Dryer Parameters

Rotary dryers offer extensive opportunity for customization in both dryer construction and process design.

Dryer Construction

When it comes to physical dryer design and construction, the primary focus centers around:

- Mode of heat delivery (direct or indirect)

- Air flow direction (co-current or counter-current, direct dryers only)

- Length and diameter

- Material(s) of construction

- Flight design and pattern

- Inlet area configuration

- Burner selection

- Breeching seal type

- Discharge breeching design

- Knocking systems

- Fuel source

Interior view of rotary dryer flights (advancing and lifting flights can be seen)

Process Parameters

When it comes to the process, several variables are used to reach desired specifications in the end product, namely:

- Percent fill

- Retention time

- Temperature profiles

- Drum slope

- Drum speed (RPMs)

- Feed rate

- Air flow velocity

- Inlet and outlet moisture

- Material flowability

Although physical construction and process parameters can be categorized separately, it’s important to note that these are often interdependent on each other, with physical construction influenced by the required process criteria and process parameters influenced by the dryer’s physical construction.

Catalyst Drying Process Development

This highly tailored approach to drying often necessitates thorough process development testing to illustrate proof of process and establish data for scale-up.

Equipped with batch- and pilot-scale equipment, the FEECO Innovation Center offers extensive testing capabilities not only for catalyst drying, but mixing, wet granulation, and coating as well. Some of the industry’s largest players rely on the Innovation Center to bring their processes to life and optimize them for efficiency.

Rotary dryer testing in progress in the FEECO Innovation Center

Conclusion

Drying is an essential step in the catalyst manufacturing process, influencing the final product’s uniformity, mechanical strength, moisture content, and more. As the understanding of drying’s impact on catalyst properties continues to evolve, the importance of precise control over drying conditions becomes increasingly clear. Rotary dryers, with their versatility and ability to be customized to specific processing requirements, provide an ideal solution for meeting these stringent demands. By tailoring both the physical construction and process parameters of rotary dryers, catalyst manufacturers can optimize the drying step to achieve consistent and high-quality products, ensuring their catalysts perform as intended. As the catalyst industry advances, the role of drying in determining product outcomes will undoubtedly remain a focal point in the pursuit of innovation and efficiency.

FEECO is the leading provider of custom rotary dryers, with over 70 years of experience. Our dryers are backed by extensive process development capabilities and a robust offering of parts and service support. For more information, contact us today!

SOURCES

- Catalyst Manufacturing Center. Catalyst Manufacturing Center | Rutgers Department of Chemical and Biochemical Engineering. (n.d.). https://cbe.rutgers.edu/research/centers-and-programs/catalyst-manufacturing-center

- NoorithayaA., Sarkar, P., Glasser, B., Khinast, J. G., & Bishop, C. (2018). 8th World Congress on Particle Technology. In 8th World Congress on Particle Technoogy. Orlando, FL; AIChE. Retrieved September 19, 2024, from https://www.aiche.org/conferences/world-congress-on-particle-technology/2018/proceeding/paper/135a-effect-drying-on-metal-distribution-supported-catalysts-high-metal-loadings.

- Munnik, P., de Jongh, P. E., & de Jong, K. P. (2015). Recent Developments in the Synthesis of Supported Catalysts. Chemical Reviews, 115(14), 6687–6718. https://doi.org/10.1021/cr500486u

- Lekhal, A., Glasser, B. J., & Khinast, J. G. (2001). Impact of drying on the catalyst profile in supported impregnation catalysts. Chemical Engineering Science, 56(15), 4473–4487. https://doi.org/10.1016/s0009-2509(01)00120-8

- Lloyd, L. (2011). Handbook of Industrial Catalysts. Germany: Springer US.