Bucket elevators are available in a wide range of sizes. And while any size bucket elevator can vertically transport material, optimizing the size of the elevator for its intended application is the key to reducing the overall size and cost of the unit while ensuring optimum handling efficiency.

Engineers use a variety of calculations to determine the optimal size for a given elevator installation, adjusting the different variables to hone in on the most efficient solution. The following provides an explanation on the basic principles behind sizing a bucket elevator that allows for maximum handling capacity from the smallest unit possible.

Bucket Elevator Type (Centrifugal or Continuous)

The first and most critical aspect in sizing an elevator is determining the bucket size. But because continuous and centrifugal elevator designs rely on different types of buckets to meet the contrasting styles of loading and discharge, engineers must first determine whether the elevator will be of the continuous or centrifugal design.

The choice between the continuous and centrifugal configurations is dependent on whether or not the material to be handled is fragile or easily aerated. Fragile materials, or those requiring gentle handling, are best handled with a continuous elevator, while centrifugal elevators are selected for materials where degradation is not a concern (there are two exceptions to this: potash and sand; almost all potash elevators are continuous and almost all sand elevators are centrifugal).

Continuous discharge belt elevator (left) and centrifugal discharge belt elevator (right)

Bucket Style

Once the bucket elevator type has been determined, engineers can select from the available bucket styles within the chosen category to determine what bucket size options are available to them.

The most common types of buckets used with centrifugal elevators are the AA and AC designs. These buckets are engineered to handle the digging and scooping action characteristic of the centrifugal elevator.

With a continuous elevator, medium-front (MF), high-front (HF), and super-capacity (SC) are the most common selections. Continuous style buckets are designed to facilitate a gentle discharge of material by utilizing the back of the preceding bucket to guide material into the discharge chute.

All bucket styles are available in a wide range of sizes to accommodate the demands of any application.

Using Bucket Size as a Starting Point

Once the engineer has selected the bucket style, he or she can select a bucket size. Since bucket size is a flexible variable engineers can work with to optimize the overall size of the unit, they typically start by selecting a size within the range of what’s needed to meet the capacity and discharge height requirements.

Engineers must also pay close attention to bucket spacing (the spacing between buckets required to achieve the proper discharge action). While centrifugal belt style elevators allow for some minor adjustments to bucket spacing, continuous style and chain type elevators do not allow adjustment, so engineers must work around this parameter.

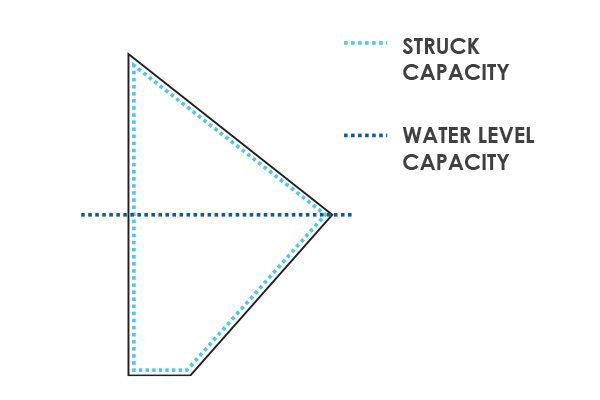

Bucket Volume Measurements

One important aspect to recognize is that bucket volume is sometimes measured in different ways, which must be accounted for in calculating the proper bucket size. Historically, engineers used a percentage of the “struck” volume or capacity of buckets, which accounted for the theoretical maximum volume a bucket could hold, taking into account the available volume between the bucket’s lower front lip and taller back plate. Today, however, the industry considers the “water level” capacity, or the maximum amount of water a bucket could realistically hold, as the standard, though some manufacturers still utilize struck capacity.

Working With Bucket Fill

Engineers can also work with bucket fill, or the extent to which buckets are filled with material, as a variable. This is expressed as a percentage and is helpful in optimizing for efficiency.

In theory, bucket fill cannot exceed 100%. However, since the bucket’s maximum volume is based on a liquid (the water level capacity), and solids can be heaped, it is possible to fill buckets beyond 100%, though this is sometimes dependent on the specific characteristics of the material. Overfilling buckets must be done with caution, however, as it is more likely to result in spillage. As a rule, FEECO engineers never exceed 100% water level, however, field upset conditions or fluctuations in feedstock can sometimes result in bucket fill exceeding 100%.

Factoring Bulk Density into Bucket Sizing

The engineer must also factor the material’s bulk density into the sizing equation, as this will determine how much volume the material will occupy, which will in turn influence the bucket size. For example, one pound of biochar takes up significantly more space than one pound of gold ore, so in speccing out a bucket elevator for handling 100 tons per hour, the biochar application will require much larger buckets to reach 100 TPH.

Belt/Chain Speed

To a lesser extent, engineers also work with belt or chain speed in optimizing elevator size.

Belt or chain speed is a factor of achieving the proper discharge, which depends on whether the elevator will be continuous or centrifugal. This is because centrifugal elevators must move at a minimum speed in order to achieve the centrifugal force needed to “throw” material out of the bucket as it passes over the head pulley. In contrast, continuous elevators operate at much slower speeds to facilitate gentle handling.

Because belt or chain speed must fall within a given range in order to reach the desired discharge action, adjusting this speed does not allow for large increases in capacity. Instead, it allows engineers to make small incremental changes in speed in order to optimize the bucket size. Depending on the exact operating conditions, for example, an increase of 10 FPM (feet per minute) might provide a 5% reduction in bucket fill, allowing the engineer to decrease the bucket size and therefore reduce the overall size of the unit.

Additional Bucket Elevator Sizing Requirements

Once the bucket size has been finalized, engineers can move on to sizing the remainder of the elevator: the casing.

Bucket Elevator Casing

Casing is sized to be as small as possible, while still allowing for ample clearance between the casing and passing buckets, as well as other internals such as chains and pulleys.

Boot casing of a bucket elevator with a screw-type take-up (screw take-up not yet installed)

In general, casing for a chain style bucket elevator should allow for a couple inches of clearance on both sides of the bucket. So if the bucket is 16” x 8”, the engineer may select a 20” x 48” casing; 20” allows for 2” of clearance on each side of the buckets, while 48” accounts for the depth, providing ample clearance for the buckets and all internals to move around the sprocket.

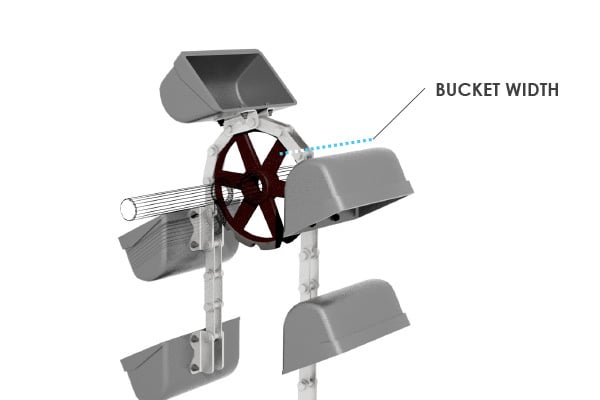

As shown below, belt style bucket elevators are a little different since the belt is slightly wider than the buckets, and the pulley is slightly wider than the belt. So in sizing a belt elevator, engineers measure the clearance against the pulley width instead of the buckets.

FEECO adds a small amount of additional width to the casing to ensure clearance and mitigate the need for chain guides, which are sometimes used to prevent the sway of chain that would cause buckets to contact and potentially damage the casing.

Casing must be sized larger if super-capacity buckets are chosen, as these high-capacity buckets require dual chains instead of a single chain. Unlike single chain bucket elevators where buckets are mounted onto the chain at their center point, buckets on a dual chain are mounted on the bucket sides, requiring additional clearance at the sides to account for the added chain width.

Conclusion

The process of sizing a bucket elevator, while simple in theory, requires an experienced engineer that will consider all relevant factors to size an elevator that is as efficient as possible. This includes taking into account the unique characteristics of the material itself, as well as other factors such as bucket size, spacing, chain or belt speed, and more.

FEECO has been manufacturing custom industrial bucket elevators for every industry since 1951. All of our elevators are designed around the unique requirements of both the material and facility for a highly efficient system built with longevity in mind. We also offer a comprehensive parts and service program to inspect and repair bucket elevators in order to keep them running their best. For more information on our bucket elevators, contact us today!