As the amount of arable land per capita declines in the face of a growing global population, the need to improve agricultural productivity is critical. At the same time, the inefficient use of fertilizer products has brought about several environmental issues with devastating effects on groundwater and ecology, prompting an urgent call for more efficient fertilizer use.

Combined with a growing understanding of crop nutrition, these factors are driving the specialty fertilizer market, ushering in a new generation of smarter, more efficient products. Coating is one technique leading the way, as it can not only be used to produce specialty products, but also to improve the quality of existing products.

About Coating for Specialty Fertilizers

Coating is a valuable tool for producers because it requires significantly less capital investment in infrastructure, R&D, raw materials, and market development. In some cases, producers can take a product already on the market, coat it, and produce something with added value that can be sold as a premium specialty product. By this approach, producers can simply integrate a coating line into their current production facility, or use an existing coating line when available, instead of having to invest in an entirely new process and plant.

In a broad sense, specialty fertilizers cover a wide range of products designed to improve performance in a way that both maximizes crop nutrition and minimizes environmental impact. Through coating, this can be achieved in several ways:

Controlling Release Properties

Controlled-release fertilizers (CRF) are becoming increasingly more common in modern agriculture. Coatings are widely used in this effort to control the release rate of the nutrients contained within the granules.

The ability to control the rate of nutrient release significantly improves nutrient management and the economics of crop nutrition by:

- Minimizing nutrient losses

- Feeding the plant at the right time

- Increasing nutrient use efficiency (NUE)

- Reducing potential for nutrient leaching and associated environmental risks

- Reducing labor due to fewer required applications

- Improving yield

How Controlled-Release Coatings Function

While different types of coatings may function in varying ways, in general, coatings in this context typically center around delaying the solubility/rate of moisture absorption of the granule, as this (along with temperature) is a primary factor in nutrient release.

Waxes, oils, natural and synthetic polymers, and more, are all used as coatings to create controlled-release products.

Improving Nutritional Value

Another way in which coatings are being used to create specialty products is through added nutritional value. Providing a well-rounded approach to crop nutrition by addressing the specific nutrient needs for a given application is quickly becoming the agricultural norm. This includes both single nutrient fertilizers, such as nitrogen, potassium, and phosphate, as well as multi-nutrient fertilizers such as MAP, NPK, and more.

Sulfur, for example, is a secondary macronutrient that has long been a fertilizer coating of choice, particularly with urea, a nitrogen source vulnerable to large nutrient losses, in an effort to address sulfur deficiencies caused by the implementation of the Acid Rain Act.

Nutritional value can also be enhanced through the use of micronutrients as coatings to address regionally specific deficiencies, such as zinc (Zn), manganese (Mn), copper (Cu), iron (Fe), and boron (B). The inclusion of these micronutrients provides a more well-balanced approach to nutrition and in some cases, may also improve nutrient uptake as a result of the interactions between the various nutrients.

In addition to micronutrients, beneficial additives can also be included as a coating in order to enrich the soil and provide a thriving environment for growth.

Improving Handling and Storage Characteristics

In addition to controlling release properties and adding nutritional value, coatings are also widely used to create premium products that look great, handle and store well, and offer optimal application qualities.

Anti-dusting and anti-caking agents are widely used to create dust-free fertilizers that won’t cake during storage, and will provide uniform and predictable application results. This ensures that the producer’s investment remains intact, while customers receive a product with the quality they expect. As such, coatings used in this manner can often reduce or eliminate costs associated with product loss from dust, spoiled or caked product, or otherwise.

In this way, oils, polymers, waxes, and other hydrophobic coatings are used to encapsulate the granules, preventing unwanted moisture absorption, dust generation, and improving flowability. Some coatings may even serve multiple functions, improving handling and storage properties while also providing added nutritional value.

Urea, shown here coated (right) and uncoated, is the most widely utilized source of nitrogen. Urea is often coated to reduce nitrogen losses and improve nutrient uptake, while also eliminating caking issues. The coating also provides a dust-free product while improving handling and storage characteristics.

Achieving Optimum Coating Quality

A well-coated product looks simple, but is actually the result of extensive engineering. There are a number of variables that influence the coating process, and finding the right combination of parameters for a new product can be a challenge in the face of so much variability in coatings and fertilizer products.

Choosing the Right Coating Equipment

While several coating devices are available on the market, the industry standard for premium specialty fertilizer products is the coating drum.

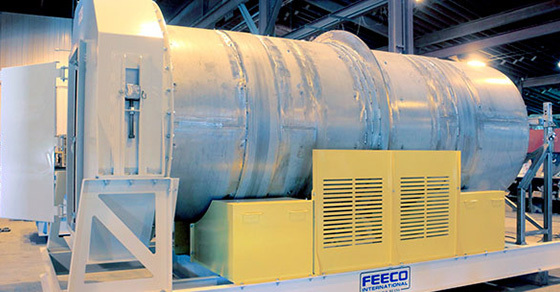

FEECO Coating Drum

Coating drums utilize rotary drum technology with an integrated spray system to apply and distribute coating onto fertilizer granules. As granules move through the drum, the coating solution is sprayed onto the material bed. The tumbling action that occurs as the drum rotates promotes an even distribution of the coating throughout the bed. Tumbler flights can be added to assist in bed agitation for maximum dispersion and uniformity.

Testing the Fertilizer Coating Process

Many variables affect the outcome of coating. When developing a novel coating process or optimizing an existing process, testing such as that carried out in the FEECO Innovation Center may be necessary. Testing allows these variables to be worked around and manipulated in order to determine the parameters needed to achieve the desired result. Some of the key factors that influence the coating process include:

- Surface characteristics of the material to be coated

- Coating temperature

- Material temperature

- Coating application rate

- Material feed rate

- Spray method and location

- Nozzle type

- Drum fill percentage

- Retention time

- Drum speed

A coating process is tested in the FEECO Innovation Center

The FEECO Innovation Center is a state-of-the-art facility that offers scalable coating drum testing as a stand-alone process, as well as part of an integrated component of an entire granulation line. Fertilizer coating can be tested at both batch and pilot scale, with the data gathered during testing then used to scale up the process to commercial scale. Material samples of varying parameters can be produced for further testing trials.

Conclusion

In business since 1951, FEECO is a global leader in process and product development, custom equipment, and parts and service support for the specialty fertilizer industry. In addition to our fertilizer production equipment and complete fertilizer granulation lines, we offer custom coating drums, as well as process and product development around both granulation and coating. For more information on our coating or granulation capabilities, contact us today!