Rotary Dryer Testing

With expertise dating back to 1951, the FEECO Innovation Center has the knowledge and equipment necessary to support your bulk solids drying test needs. Whether testing the drying process as a preconditioning step in a larger process, looking to optimize an existing process, or designing a new one, the Innovation Center offers a number of options to suit your objectives.

Dryer testing is typically conducted in two stages:

Proof of Process: A continuous testing phase that aims to establish the equipment setup and parameters required for continuous production of your specific material.

Process/Product Optimization: An in-depth study to optimize your specific material’s characteristics and/or production parameters in an industrial setting.

The data gathered during testing is then used to scale up the process and engineer a custom rotary dryer.

Note: In addition to rotary dryer testing, the Innovation Center also has a fluid bed dryer available for testing.

COMMONLY TESTED MATERIALS

The FEECO Innovation Center has extensive experience in testing a wide range of materials. Materials that are frequently tested in the Innovation Center include:

- Fertilizers (NPK, MAP, DAP, and more)

- Minerals and ores (limestone, gypsum, potash, etc.)

- Chemical products (pigments and dyes, detergents, etc.)

- Organics (Bagasse, manure, chicken litter, etc.)

- Industrial by-products and wastes (EAF dust, fly ash, FGD gypsum, etc.)

PROCESS & PARTICLE ENGINEERING

Various material characteristics and process parameters can be targeted to yield a process that performs efficiently and produces the desired product results. Parameters that can be targeted and adjusted during testing might include:

- Attrition

- Particle Carryover

- Bulk Density

- Crush Strength

- Flowability

- Moisture Content

- Particle Size Distribution

- Temperatures

FLIGHT (MATERIAL LIFTER) SIMULATOR TESTING

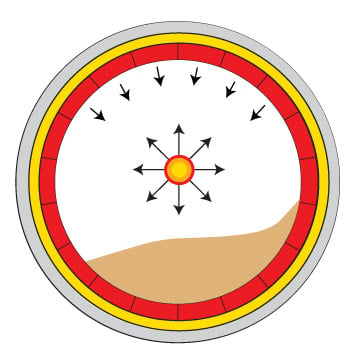

In addition to a pilot-scale test dryer, the FEECO Innovation Center is capable of testing various flight (material lifter) designs and patterns in a flight simulator. The 45″ diameter x 24″ deep unit simulates process conditions in a commercial-scale unit to assess and fine-tune existing and proposed flight designs and patterns. A clear cover allows for visual observation. Several criteria can be evaluated during flight simulator testing, including:

- Number of flights

- Flight design

- Flight pattern

- Loading (amount of material in drum at once)

- Drum speed (RPM)

- Moisture content

- Particle size distribution

RESOURCES

DRYER TESTING ARTICLES

Making the Switch from Reactive to Preventive Maintenance

The benefits of a preventive maintenance program are well documented – reduced downtime, lower maintenance costs, improved safety, and longer equipment …

Principles of Heat Transfer as Applied to Rotary Dryers, Rotary Kilns, and Rotary Coolers

Whether you are using a rotary dryer, rotary kiln, or rotary cooler, there is one thing that all these instruments have …