Prized for its extremely porous surface area, the superior performance of activated carbon as an adsorbent lends itself to a number of applications spanning across a range of industries.

One of the major benefits to activated carbon is that it is capable of being restored, meaning that “spent” carbon, or carbon saturated with the adsorbed components, can be desorbed of the components to yield an activated carbon that is again ready for use.

Regeneration

Albeit large, activated carbon does have a finite adsorption capacity. Throughout the course of its use, this capacity becomes diminished as the activated carbon adsorbs more components onto its surface. Once the activated carbon has reached capacity, it can no longer be effectively used. The now “spent” carbon can either be sent to a landfill or incinerator for disposal, or recycled through regeneration. Typically powdered activated carbon (PAC) is not regenerated, but rather, disposed of, while granular activated carbon (GAC) is regenerated.

Regeneration, often referred to as reactivation, is a method of thermally processing the activated carbon to destroy the adsorbed components contained on its surface. In regeneration, the adsorbed components are almost completely removed, yielding a regenerated carbon that can again function as an adsorbent.

It’s important to note that regeneration and reactivation actually refer to two technically different processes. However, these terms are frequently used interchangeably across many industries, and as such, are used so in this article.

Benefits to Regeneration

The use of regenerated carbon offers a host of benefits, as summarized below:

More Environmentally Friendly

Utilizing regenerated carbon over new activated carbon is a more sustainable approach, incurring fewer greenhouse gas emissions than the production and use of new activated carbon.

Furthermore, this more sustainable approach may allow companies to comply with emissions permit levels, as well as state and local environmental regulations and EPA guidelines.

Reduced Costs & Liability

Regeneration eliminates the disposal costs and liabilities associated with otherwise disposing of the spent carbon.

Costs are further reduced because the use of regenerated carbon costs less than the purchase of new activated carbon.

How Regeneration Works

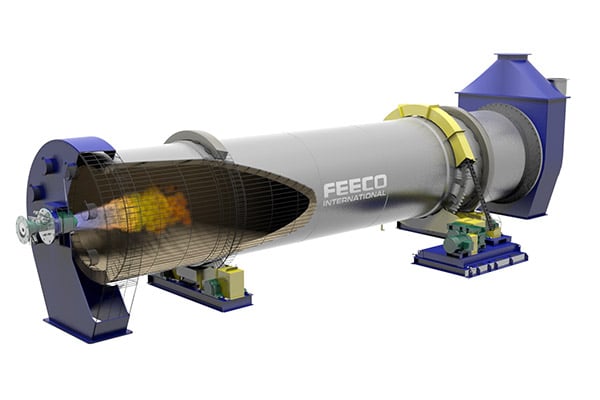

Regeneration is most commonly carried out using a thermal approach in which high temperatures are used to destroy the adsorbed components. While this process can differ based on the source material and the adsorbed components, in general, it happens in three stages.

The material is first dried. Once the material has been dried to the desired moisture content, volatilization can occur. The material is heated up to around 1000º F, which volatilizes 75 – 90% of the adsorbed materials. At this point, steam is injected into the system to remove the remaining volatiles and “reactivate” the carbon.

The result is near-completely restored activated carbon ready for reuse. During this process, it is common to have carbon losses between 5 – 10%. For this reason, each time spent carbon is regenerated, that amount of new activated carbon will need to be added to make up for the losses.

Depending on various factors, these stages may be carried out all in one piece of equipment, or multiple pieces. Upon regeneration, the activated carbon is commonly cooled in a rotary cooler before it moves on to shipping, storage, or reuse.

Multiple Hearth Furnaces vs. Rotary Kilns for Regenerated Carbon

While various types of thermal devices can be used for the regeneration of spent carbon, rotary kilns and multiple hearth furnaces are the two most commonly used approaches by far.

Both multiple hearth furnaces and rotary kilns have proven effective in the regeneration of activated carbon. In comparing the two reactivation methods, a study from the EPA found several advantages and disadvantages to be apparent.¹

Cost

While maintenance and operation costs are comparable between the two systems, multiple hearth furnaces require double the capital cost of a rotary kiln.

Total process costs were slightly lower for rotary kilns as well.

Fuel Consumption

Rotary kilns consume around double the amount of fuel that multiple hearth furnaces do.

Operational Skill Level

Rotary kilns tend to require a less skilled operator than multiple hearth furnaces.

Lifespan

Lifespan was found to be longer in multiple hearth furnaces.

Exhaust Handling

Both systems require the use of an exhaust handling system to control emissions.

Carbon Loss

Carbon losses between the two systems were comparable.

In addition to these factors, capacity is often a determining consideration between the two types of equipment; multiple hearth furnaces offer significantly greater capacities. However, rotary kilns are more favorable for smaller applications.

On-site vs. Off-site Regeneration

Companies using activated carbon have many options when it comes to regeneration.

Often times, the same company that produces the activated carbon will offer a regeneration service as well. This allows companies to send their spent carbon back to the manufacturer for regeneration, and then get it back, ready for reuse.

Many activated carbon producers will also offer their customers a “carbon pool” or sharing option. Here, customers that do not require getting their specific carbon back can submit their spent carbon along with other companies in order to keep costs low.

In some industries, large-scale or remote operations may justify the need for their own on-site regeneration facility, such as those found in the gold recovery industry.

Conclusion

Activated carbon is a powerful adsorbent with many uses. The opportunity to regenerate carbon offers many benefits over purchasing fresh activated carbon.

FEECO offers direct- and indirect-fired rotary kilns for the production and regeneration of activated carbon. For more information on our heavy-duty kilns, contact us today!

Sources:

- United States. Environmental Protection Agency. Municipal Environmental Research Laboratory – Office of Research and Development. Carbon Reactivation by Externally-Fired Rotary Kiln Furnace. By Ching-lin Chen and Leon S. Directo. Cincinatti: 1980. Print.