If material needs to be moved vertically, chances are a bucket elevator is the ideal solution for the job. In fact, the versatility and configurability of this equipment make bucket elevators a common bulk material handling system in a number of different industries. What follows covers the basic operation of bucket elevators and their different styles, as well as the industries and applications in which they are and are not a fit.

Bucket Elevator Operation

In simple terms, bucket elevators vertically convey bulk materials using buckets attached to a belt or chain, which rotates around two pulleys. The buckets pick up material in the boot section, carry it to the top of the elevator (the head section), discharge material, and finally, return to the starting point to pick up a new load.

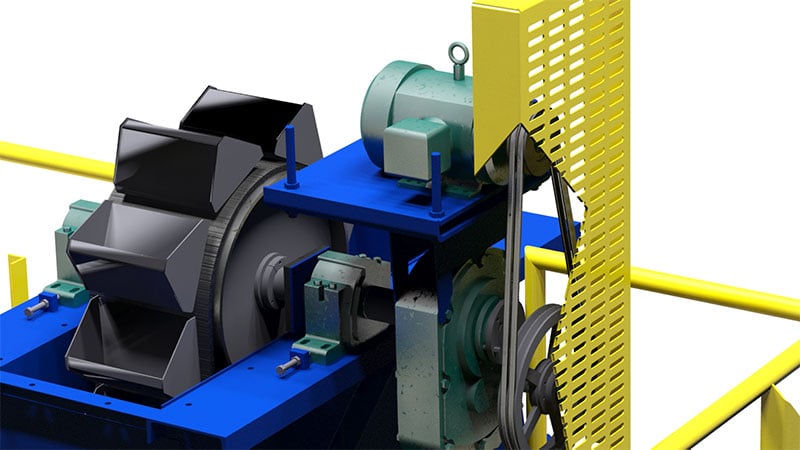

This 3D rendering of a FEECO bucket elevator illustrates the basic configuration of a belt bucket elevator. Close-ups of the head and boot section cutaways are shown below.

Bucket elevator head section

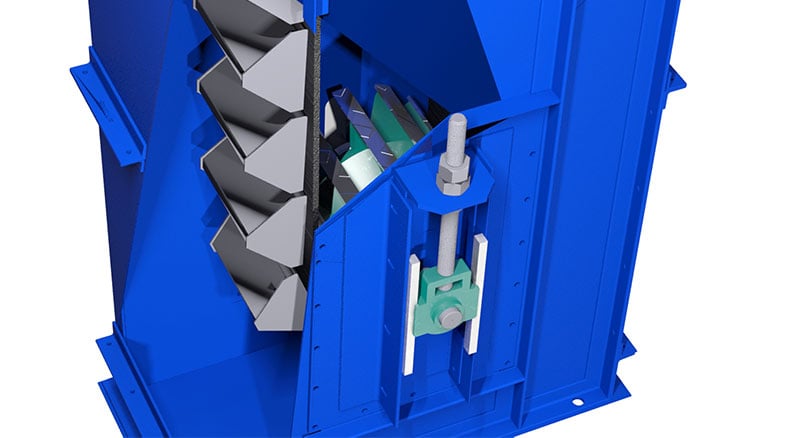

Bucket elevator boot section with take-up assembly

Bucket elevator configurations are engineered based on the application, material, required horsepower, and elevator height. Configuration options include centrifugal or continuous bucket elevators, with both models including belt and chain options.

Centrifugal Bucket Elevators

A centrifugal bucket elevator employs centrifugal force to throw material out of the buckets as they travel over the head pulley or sprocket. This type of bucket elevator operates at a higher speed and utilizes buckets spaced further apart compared to continuous bucket elevators. The result of the high speed and bucket spacing is optimized material fill and reduced interference between buckets.

Centrifugal bucket elevators are available with a belt or single chain.

Continuous Bucket Elevators

Continuous bucket elevators operate at a lower speed with closely spaced buckets compared to centrifugal bucket elevators. This action permits material flow over the backside of the preceding bucket to assist with discharge. Additionally, extended sides on the buckets gently guide material into the discharge spout. These modifications create an ideal approach for fragile, abrasive, and sluggish materials. Benefits include limited material aeration and minimized breakage of friable or fragile material.

Continuous bucket elevators are available with a belt, single chain, or double chain.

Continuous discharge belt elevator (left) and centrifugal discharge belt elevator (right)

Elevator Bucket Options

In addition to varying configuration options, there are also a number of bucket style options available, with material and elevator design being primary bucket selection criteria.

Other bucket elevator features include removable top covers, access doors for easy maintenance, and horizontally and vertically heavy-reinforced, jig-welded head, boot, and intermediate sections.

Bucket Elevator Applications

Due to their versatility, bucket elevators are common in a number of industries. Examples of common bucket elevator applications include:

- Fertilizer Plants

- Limestone Processing Facilities

- Power Plants

- Pulp and Paper Mills

- Steel Production Plants

Bucket Elevator Head Sections at a potash facility

Common Bucket Elevator Materials

Bucket elevators can handle a wide range of free-flowing materials with varying characteristics. Light, fragile, heavy, and abrasive materials can all be transferred using a bucket elevator. Examples of materials conveyed via bucket elevator include:

- Aggregates

- Animal Feeds

- Calcined Coke

- Fertilizer

- Fly Ash

- Frac Sand

- Lime

- Minerals

- Potash

- Woodchips

- Coal

Pet coke in a bucket elevator

Bucket elevators are not recommended for use with material that is wet, sticky, or has a sludge-like consistency. These types of materials tend to create discharge issues, with build-up being a common problem.

After building custom bucket elevators for more than 70 years, FEECO bucket elevators are able to meet even the toughest of challenges. Whether a customer is looking to transport a dry, dusty material, or a heavy, more challenging product, FEECO can custom engineer a bucket elevator solution to meet the needs of any bulk material handling application. For more information on bucket elevators or other bulk material handling equipment, contact us today!