Rotary dryers are a significant capital expenditure, necessitating a thorough discovery process to assess the unique requirements of the system. In preparing to purchase a rotary dryer, keep the following questions in mind to protect the investment and ensure the appropriate solution is acquired.

Replacement Rotary Dryer prepared for shipment

Is a rotary dryer appropriate for my capacity requirements?

Rotary dryers are widely used throughout various industries, but as continuous equipment meant for large-scale production facilities, they are generally not the best choice for small-scale settings. Rotary dryers are typically chosen for facilities processing anywhere from 1TPH – 200TPH. Those processing small batches of material should consider alternative dryer options better suited to their capacity requirements.

Is a rotary dryer the right drying system for my product/material?

Rotary dryers are a diverse industrial drying system, but they are not a fit for all materials. They are generally not appropriate for high-moisture materials such as slurries and liquids, unless pretreatment or back mixing will precede drying.

Will any pretreatment be required?

While they can accept a wide range of materials, rotary dryers do require materials to fall within a given range of specifications in terms of moisture content and particle size.

When the moisture content falls outside of this range (specific to each material), the material may require pretreatment to bring it into a more manageable moisture range.

Similarly, material should fall within a predetermined particle size distribution (PSD) for effective drying. A crushing or grinding step may be necessary to bring material into the optimal size range.

What configuration will best suit my needs?

Rotary dryers are best designed around the specific characteristics of the material to be dried for optimal efficiency and product quality. This means the best configuration is highly dependent on the material.

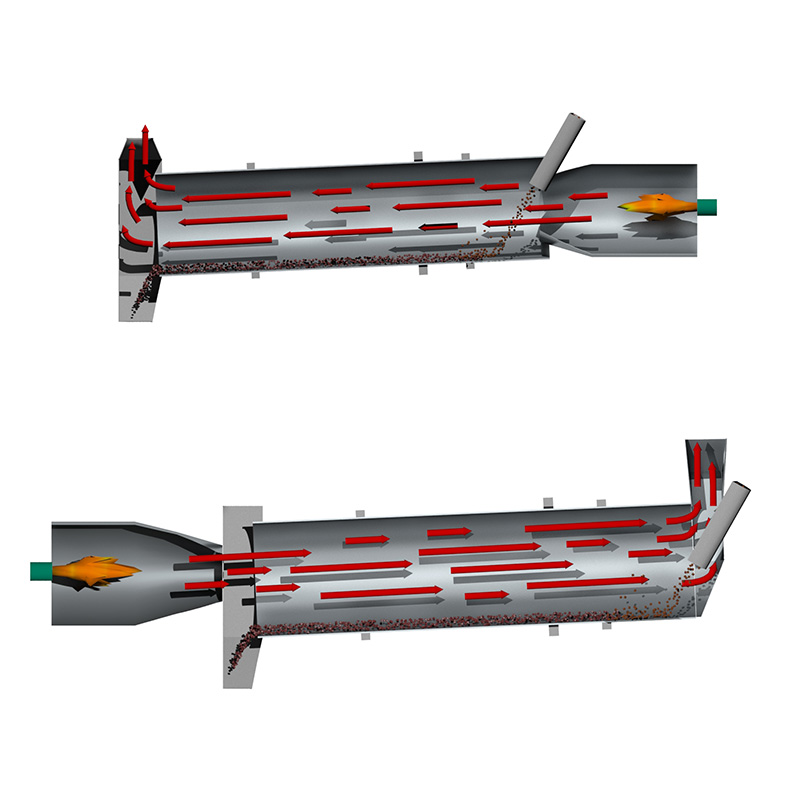

Several key aspects of the dryer must be engineered around these parameters, including air flow (co-current or counter-current), flight design and pattern, whether the dryer is direct or indirect, whether or not a combustion chamber is employed, as well as the size and diameter of the dryer and any special modifications that may be necessary to achieving process or product goals.

The 3D rendering above illustrates the co-current air flow configuration (top) versus the counter-current configuration (bottom) in a rotary dryer.

If the ideal dryer design is not clear, the rotary dryer manufacturer selected to engineer the unit will often be able to assist in defining the dryer parameters. This may come in the form of past experience, expertise, material testing, or a combination thereof.

It’s important to note, however, that not all rotary dryer manufacturers are capable of assisting in this aspect of development. Beware of those selling one-size-fits-all dryers.

What happens when something goes wrong?

Remember that the dryer will require routine maintenance and potential repairs. Consider what happens when something goes wrong; is the OEM available to assist, or will a third party service provider be required?

Does the dryer come with any sort of warranty or support from the OEM? Many plant managers have learned the hard way that not all rotary dryer manufacturers will provide assistance after installation is complete.

A FEECO Customer Service Engineer arrives on site to inspect a rotary dryer

Can my site support a rotary dryer?

The intended site must also be considered in the purchasing process. Will electricity at the site be reliable? Is the fuel source readily and economically available? What sort of regulatory requirements will govern the site’s emissions? Is there space to accommodate the dryer?

Is testing needed before engineering a full-scale unit?

Material testing may be a necessary step in the buying process. Testing is often used as a means of gathering the process and material data necessary for scale up, particularly when the application is new, or when working with materials that exhibit a high level of variation.

Pellets in a rotary dryer during testing in the FEECO Innovation Center

Will/Can an OEM assist with process/system integration?

The capabilities of individual OEMs vary significantly. Some OEMs will only provide the dryer, while others will fully assist with process engineering and integrating the unit into the existing system, along with streamlining its performance in the operation.

What sort of quality control practices do we need to be aware of?

The purchase of a rotary dryer is just like anything else, with quality ranging from poor to exceptional. When looking for a high-quality rotary dryer, ensure the chosen manufacturer adheres to a strict quality control program. Consider materials of construction, welding certifications, rolling techniques, allotted tolerances, and more.

Rotary dryer in fabrication at FEECO

What other equipment is needed to support the dryer?

Remember that several other pieces of equipment are needed to support the drying system. A complete dryer system requires an exhaust gas handling system, a burner, a combustion chamber (optional), and material handling equipment to carry material to and away from the dryer.

What can I expect in terms of maintenance?

Apart from minor maintenance procedures such as changing the gearbox oil, maintaining adequate lubrication, and the like, rotary dryers are relatively low-maintenance, though the level of maintenance required by an individual dryer depends largely on the specific demands of the application.

FEECO recommends annual inspections to catch and address any potential problems early in order to minimize maintenance and repair requirements. Rotary dryers should also be periodically realigned, as they fall out of alignment over time through normal wear and tear.

Rotary drum tire and trunnion grinding may also be necessary from time to time to recondition worn load-bearing surfaces.

Rotary dryer tire grinding in progress

Will this equipment be a fit if we want to automate our process in the future?

Automation capabilities are also highly specific to the manufacturer. That said, automation should be a consideration in the purchasing process if it is not already.

Automation is becoming increasingly more relevant to industrial equipment, allowing producers to collect and monitor data in real time, and also use trends for predictive maintenance and expedient troubleshooting and issue resolution.

How do I choose a supplier?

Identify critical objectives and evaluate manufacturers based on how they align with these goals.

Factor in other important considerations in choosing a rotary dryer manufacturer, such as material expertise and ability to customize a dryer, in order to reach the best possible outcome.

Will this equipment allow us to comply with emissions and any regulatory requirements?

Regulatory compliance cannot be overlooked. Ensure the chosen manufacturer is prepared to address emissions for compliance.

What sort of installation costs can I expect with a new rotary dryer?

Installation costs vary per site, but generally add 1 to 2 percent to the cost of the unit. The installation contractor will lay out the associated installation costs.

What are the physical base requirements for a rotary dryer?

Rotary dryers require a solid base capable of bearing both live and dead loads without distortion or vibration. This is typically handled by concrete piers and/or structural steel supports, with the specific requirements for the site laid out in general arrangement (GA) drawings.

Rotary dryer on concrete piers

Conclusion

As a large capital expenditure, rotary dryers require careful attention to detail during the buying process. Be prepared for the many questions and issues that may arise by considering the factors listed above.

FEECO is a preferred global supplier of custom rotary dryers. All FEECO dryers are backed by extensive experience and testing in our Innovation Center, and adhere to the highest quality standards in both engineering and fabrication. FEECO can provide guidance for every aspect of rotary dryers, from design, through the buying process, and including parts and service support. For more information, contact us today!