THERMAL PROCESSING EQUIPMENT

FEECO International, Inc. is an industry leader in the field of thermal processing (also known as pyro processing). All of our thermal processing equipment is custom designed around the requirements of your process and the characteristics of your material.

From industrial drying and cooling, to calcining and pyro processing, we supply:

- Rotary Dryers

- Fluid Bed Dryers

- Rotary Coolers

- Indirect Rotary Coolers

- Direct-Fired Rotary Kilns

- Indirect-Fired Rotary Kilns

We offer cost competitive designs for everything from pilot scale units, to full capacity units, and everything in between.

FEECO is capable of meeting the requirements necessary for CE marking equipment.

All FEECO equipment and process systems can be outfitted with the latest in automation controls from Rockwell Automation. The unique combination of proprietary Rockwell Automation controls and software, combined with our extensive experience in process design and enhancements with hundreds of materials provides an unparalleled experience for customers seeking innovative process solutions and equipment. Learn more >>

FEECO equipment processes such materials as:

- Limestone and Lime

- Sand and Gravel

- Industrial Waste and Sludges

- Municipal Waste

- Minerals and Ores (Copper, Iron, etc.)

- Proppants

- Fertilizers (potash, DAP, MAP, NPK, TSP)

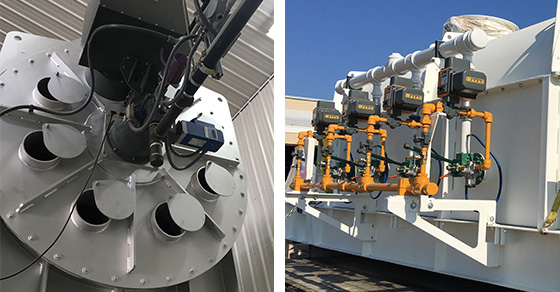

Complete Thermal Systems

In addition to single, stand-alone thermal processing units, we also offer complete systems, including feed handling, metering, and exhaust gas cleaning, as well as a variety of control systems, from a simple single control loop in a microprocessor, to a sophisticated PLC-based system with multiple control loops.

All of our systems and equipment are developed with longevity and efficiency in mind, and can be configured to a variety of specifications:

- Parallel Flow or Counter-Current Flow

- Direct or Indirect Fired

- Natural Gas, Oil, Steam, Waste heat, etc.

RESOURCES

Thermal Processing ARTICLES

In rotary kiln engineering, dams are often an overlooked yet critical component in controlling material retention and thermal efficiency. These strategically …

Fuel-Fired vs. Electric Rotary Kilns: Weighing the Pros and Cons

As industries pursue cleaner operations and greater efficiency, many producers are asking whether their rotary kilns (and in some cases, dryers) …