The high temperatures and dynamic loads associated with rotary kiln applications make proper maintenance pivotal to maximizing equipment service life, avoiding costly repairs, and preventing unnecessary downtime.

Routine Rotary Kiln Maintenance

Measurements to Monitor

Operators and maintenance personnel should regularly take several kiln measurements to monitor the unit’s mechanical condition. This includes:

- Tire Creep (how much more the tire/riding ring migrates around the drum shell during rotation)

- Cold Gap (the amount of space between the inside diameter of the tire and the outside diameter of the filler bars – floating tire assemblies only)

- Float (drum axial loading on thrust roller, discussed below)

- Tire and Trunnion Roller Diameters

- Tire and Trunnion Roller Hardness

Gear Maintenance

Units employing a gear and pinion drive assembly must ensure that gears are properly lubricated at all times. The girth and pinion gears should also be interfacing properly, with adequate root gap. This minimizes wear on drive components, which are costly to replace. Further, gears cannot typically be repaired, leaving replacement as the only option.

Replacing Worn Kiln Components

Replace worn components as needed. FEECO recommends a preventive approach to replacement to avoid extended shutdowns due to unexpected failures, as well as to prevent further damage from added stress on all components.

Maintaining Rotary Kiln Refractory

A rotary kiln relies on its refractory lining to operate efficiently and maintain the required temperature within the unit, as well as protect the kiln shell from the high temperatures within.

Unfortunately, these liners can degrade over time, causing a loss in kiln efficiency. Also in some cases, an object, such as hard material build-up, may find its way into the kiln and damage the refractory. The damage may seem minimal, but can cause a material trap or cold spot, resulting in process inconsistencies.

Furthermore, since the liner is meant to absorb the heat before it can come into contact with the drum shell, any thin or damaged spots may result in heat distortion of the drum shell. A distorted drum shell can cause refractory issues, as well as serious damage to several components and will need to be replaced as opposed to repaired.

Because of the significant role that this component plays in protecting the kiln, FEECO recommends routine inspections by a qualified service provider. Operators and maintenance personnel should also be trained in recognizing the signs of a potential failure.

A FEECO Customer Service Engineer inspecting refractory

Burner Maintenance or Replacement

While FEECO only utilizes high-quality burners that have proven to be reliable, issues can still occur. Parts such as the burner nozzle, burner cone, and burner sensors may need to be replaced for the kiln to continue to operate as designed.

In the case of old equipment, it may be beneficial to upgrade the burner. Burner technology is constantly progressing and a new burner may result in greater energy efficiency and material output, making for a cost-effective upgrade.

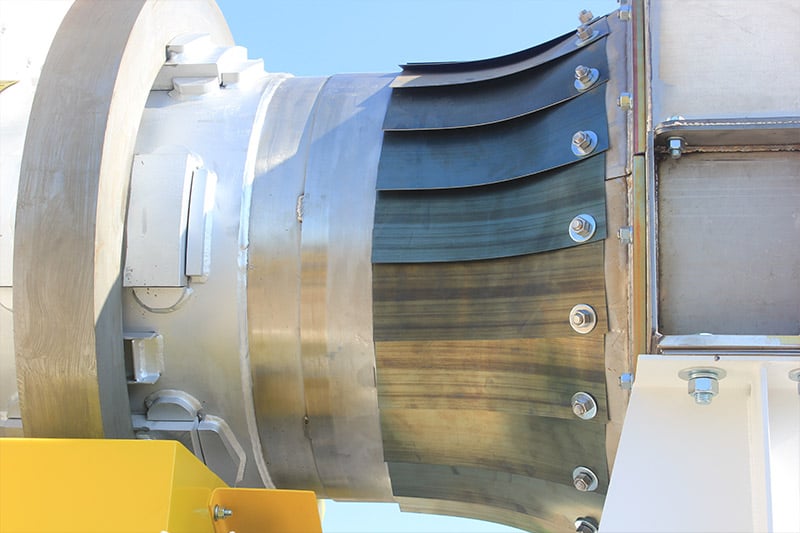

Burner (mounted on a combustion chamber)

Breeching Seal Repair & Replacement

Rotary kiln seals play an essential role in process efficiency by preventing air ingress. This ensures the internal processing temperature is maintained so the reaction can be carried out efficiently.

Seals also prevent material from escaping the unit. FEECO kilns are specifically designed to funnel exhaust air, along with dust, to a controlled area. The design is configured to discharge the maximum amount of process material, while still maintaining the desired internal temperature.

Worn out seals can alter this precise system, resulting in poor dust control and varying kiln temperatures, ultimately leading to added plant clean-up and process inconsistencies.

Leaf seal

Common Maintenance Issues

The most common wear-and-tear issues are:

Kiln Misalignment

Misalignment is one of the most common issues seen with any type of rotary equipment, kilns included. Alignment issues are common, but should not be taken lightly, as they affect all components of the rotary drum; when a kiln falls out of alignment with its original horizontal and vertical axes, structural and mechanical components experience excessive stress and subsequent wear or damage, making proper alignment a top priority. The drum should always be positioned properly on trunnion bases without deviation from its centerline axis of rotation.

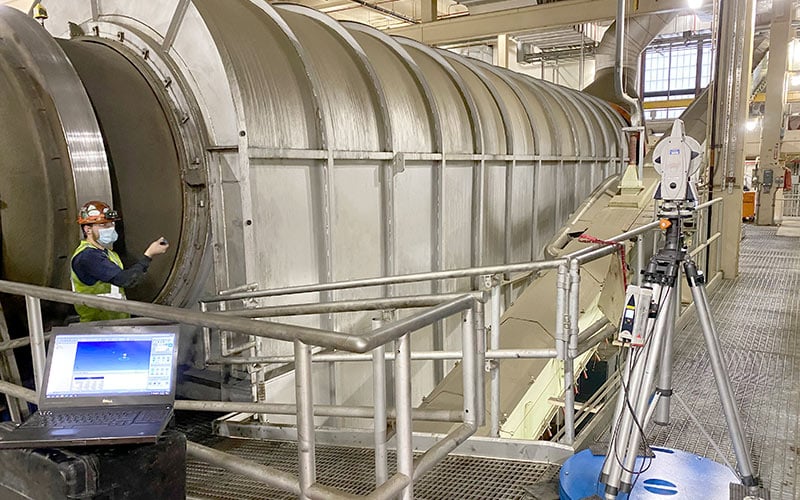

Misalignment can occur for a variety of reasons, but should be corrected as quickly as possible to prevent further damage. While a few different types of rotary kiln alignment services are available on the market, FEECO recommends the laser approach.

The use of the laser alignment technique allows technicians to carry out the correction faster and more accurately than traditional methods.

A FEECO Customer Service Engineer Conducts a Laser Alignment

Worn Tires & Trunnions

Wear on tires (riding rings) or trunnion wheels (also known as support or carrying rollers) puts undue stress on various mechanical components and should be addressed as quickly as possible to avoid further damage.

In most cases, when riding rings and rollers become worn, they can be reconditioned/resurfaced through grinding, in which trained technicians use specialized equipment to grind away surface wear, revealing the undamaged surface below. In cases of excessive wear, replacement may be the only option, as the kiln slope is otherwise affected.

It’s important to note that worn tires or trunnions typically indicate an underlying issue, most often an alignment problem. As such, the drum should be investigated to identify and resolve the root cause of wear. If the underlying issue is not addressed, wear on tires and trunnions will quickly resume after grinding.

Axial runout, or the misalignment between the drum and its riding rings/tires, can also occur with tires if tire creep is not kept within a certain range. Axial runout is often indicated by vibration or wobbling of the tire.

Improper Float

Float refers to the positioning of the drum between thrust rollers; ideally, the drum should “float” between the uphill and downhill thrust rollers, not riding hard against either one.

Thrust rollers prevent the drum from drifting on a longitudinal axis. If the drum begins to drift longitudinally (typically downhill), the thrust roller provides a rotating point against which the tire can ride.

While intermittent contact between the tire and thrust roller is permissible, anything beyond that will begin to damage both components and should be corrected as quickly as possible. In addition to damaging these key components, the drum will also experience thrust overload, putting additional pressure on bearings and roller shafts. Excessive thrust can also be a result of over-skewing the bearings in an attempt to train the drum (for this reason it is important to avoid excessive skewing).

The process of correcting drum float is referred to as “training” the drum back into position. This is done by performing a laser alignment and skewing trunnion bearings in very small increments to influence the direction of the drum and the amount of longitudinal thrust it experiences. Training should only be conducted by a trained professional, as the potential for extensive damage is high if not carried out properly.

Kiln Shell Issues

A rotary kiln shell designed for its intended level of duty should experience little-to-no issue. However, a kiln’s shell can begin to experience issues if the unit is not properly maintained or was operated improperly. This might include thin spots, ovality problems (when the shell is no longer perfectly round), distortion or deforming of the shell, cracks at weld points, as well as other problems. One common cause of shell issues is when operators do not keep the kiln rotating with a hot load, such as in the event of a failure or power outage. This prolonged exposure to concentrated heat can damage the shell.

Top Maintenance Tips

In addition to the basic maintenance procedures associated with all rotary drum equipment (lubricating the gear box, changing the oil, etc.), FEECO recommends the following to maximize kiln service life and avoid unpredictable operation:

Prioritize Preventative Maintenance

The most cost-effective approach to maintenance is a preventative one. Preventative maintenance for rotary kilns centers largely around routine assessments of the unit, as well as proactively replacing worn kiln parts. Build a solid foundation of schedules and procedures to conduct at daily, weekly, and monthly intervals. Catching problems early allows the issue to be circumvented before it can evolve into something more serious or cause process upsets.

In addition to on-site personnel performing regular inspections, FEECO recommends all kilns undergo an annual inspection as well. Annual evaluations conducted by the OEM offer much deeper insight into the kiln’s mechanical condition. In especially harsh operating conditions, these assessments may be required more frequently.

Be sure operators and maintenance personnel are properly trained in both the operation and care of the unit. On-site personnel should also thoroughly document all inspections and any changes made (roller adjustments, key measurements, etc.).

Select the Right Rotary Kiln Service Provider

Not all rotary kiln service providers are the same. In selecting a provider, be sure to thoroughly vet vendors. Moreover, not all service providers can provide all services, so be sure to select a provider that can meet all of your maintenance requirements.

Take care in selecting a provider that prioritizes safety, efficiency, and getting the job done right the first time. Further, select a provider that will not just treat the symptoms, but will work to identify and resolve the root cause of the issue(s).

Prioritize Proper Lubrication of All Components

Ensuring all components are properly lubricated is a vital step in preventing future damage. Follow OEM recommendations for all components in terms of type of lubricant, amount, and frequency required. Note that not only is too little kiln lubrication a problem, but too much can also be problematic, presenting a fire hazard, damaging grout, and more.

Keep a Parts Inventory

Keeping an adequate supply of wear-critical and operational spares is pivotal to minimizing downtime; having the right replacement parts on hand in the event of an issue can mean the difference between days and weeks of lost production.

Rotary Kiln Audits

Establishing an effective maintenance program can be overwhelming, particularly when the condition of the operating unit is unclear.

In this effort, FEECO offers audits to assist plant managers and maintenance personnel in establishing a baseline of benchmark data, identifying any areas of concern, troubleshooting issues, and laying out a preventive maintenance schedule, as well as addressing any identified problems.

Thermal imaging of a rotary kiln captured during an equipment audit. Thermal imaging can help to identify potential problems in the kiln shell by indicating hot spots.