Whether an industrial process is new or well established, the path from concept to production is often complex and unclear. Spanning over a time frame of months and even years, adequately moving through the various stages of process development is the foundation of a successful commercial operation.

The following information provides an overview on the journey from concept to commercial production in both agglomeration (granulation) and high-temperature thermal production techniques, including how each testing phase of process development is conducted.

Please note that while this information provides a guideline to process development in general, some information may be specific to testing in the FEECO Innovation Center. Additionally, it’s important to recognize that not all projects will require each stage. Every process has unique requirements and may move through the stages differently.

Breaking Down Process Development

Process development can be roughly divided into four main steps:

- Proof of Concept/Feasibility

- Proof of Product

- Proof of Process

- Process/Product Optimization

Proof of Concept/Feasibility

Obtaining proof of concept is the first and most critical stage of process development. Proof of concept establishes feasibility, that is, whether or not the given process or product is within the realm of possibility.

How Proof of Concept is Established

Feasibility, or proof of concept is established through conducting small, batch-scale tests. Testing is at its broadest scope in this stage of the process, with the focus centering around proving or disproving the concept at a high level.

Proof of Concept: Agglomeration

In an agglomeration process, proof of concept typically involves testing the representative sample to see how it responds to agglomeration with the assistance of water or a binder. In addition to determining whether or not the material is capable of agglomeration, this testing gives process engineers a glimpse into how easily the material will agglomerate, and any potential challenges they may face should testing move forward.

Testing is carried out in batch-size/bench-scale equipment.

A Process Engineer in the FEECO Innovation Center evaluates a material’s potential for agglomeration on a batch-scale disc pelletizer.

Proof of Concept: Thermal

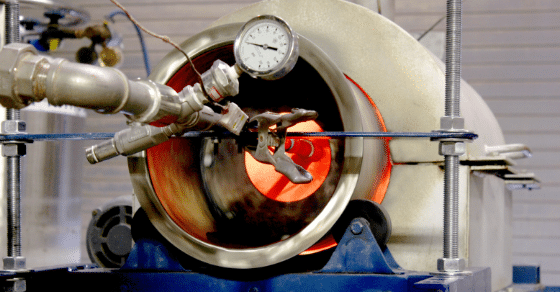

In developing a high-temperature thermal process, proof of concept testing illustrates how a material will respond to thermal treatment, and whether or not the way in which it responds is likely to meet the intended goal. A Thermal Gravimetric Analysis (TGA; where mass is measured as a function of temperature) and Differential Scanning Calorimeter (DSC; where the amount of heat needed to change the temperature of the material is measured as a function of temperature), and chemical analysis may be necessary at this stage depending on what is known about the material.

An indirect-fired batch kiln (also called a calciner) is used to show proof of concept in a high-temperature thermal test in the Innovation Center.

Key Takeaway

The establishment of proof of concept shows that the process merits further exploration and is at least to some extent, possible. If proof of concept cannot be achieved, the project should not be explored further, as it has been deemed implausible under the given circumstances.

Proof of Product

Proof of product follows the establishment of proof of concept. While proof of concept serves to demonstrate that the idea is feasible at some level, proof of product takes the concept a step further and examines whether or not a product can be produced to the desired specifications.

How Proof of Product is Established

Proof of product works off of the data and observations gathered during proof of concept testing to build on what is already known about the material. Here, additional batch-scale tests are conducted to fine-tune the process to see if the desired end product results are within reach.

Proof of Product: Agglomeration

In agglomeration testing, proof of product examines the equipment configuration and process parameters most likely to obtain the desired results. This might involve testing different types and combinations of equipment, variation in feedstock specifications, and more. Key specifications at this stage vary, but in general, particle size, moisture content, and crush strength are most often targeted.

Proof of Product: Thermal

In thermal testing, a batch kiln (direct or indirect) is used to gain additional data on the unique parameters required to produce the desired results. This might involve evaluating retention times, temperature profiles, atmospheric conditions, and more.

Key Takeaway

The establishment of proof of product illustrates that the desired product can be both physically and economically produced. It also works to identify the specific process parameters necessary to reach the desired results. In some cases, testing may show that the product cannot be economically produced. It may also show that despite a positive response to proof of concept, the product cannot be produced to desired specifications.

Proof of Process

Unlike the first two stages of testing, proof of process is a pilot-scale, continuous process. This stage of processing demonstrates that production is possible on a continuous scale and provides a clearer picture of the equipment and production requirements necessary for commercial production.

It’s worth noting that continuous processing is not the end goal in all cases; some operations may be more comfortable sticking with a batch operation, or may not have the volume to support a continuous process. In these cases, the company can move on to refine the process at batch scale and establish the equipment and process parameters needed for production.

The move to a continuous process can be complex given that a continuous flow of product is introduced. This means that each step will need to work in seamless coordination with the steps around it to accommodate continuous flow.

Since not all variables scale up linearly, many challenges can arise in upgrading from a batch to a continuous process. In essence, some process parameters do not increase proportionately, so data for scale-up to the intended capacity must be determined.

How Proof of Process is Established

The anticipated equipment configuration is set up for continuous processing. Material is continuously fed to the system, while Process Engineers observe the process and make adjustments as needed.

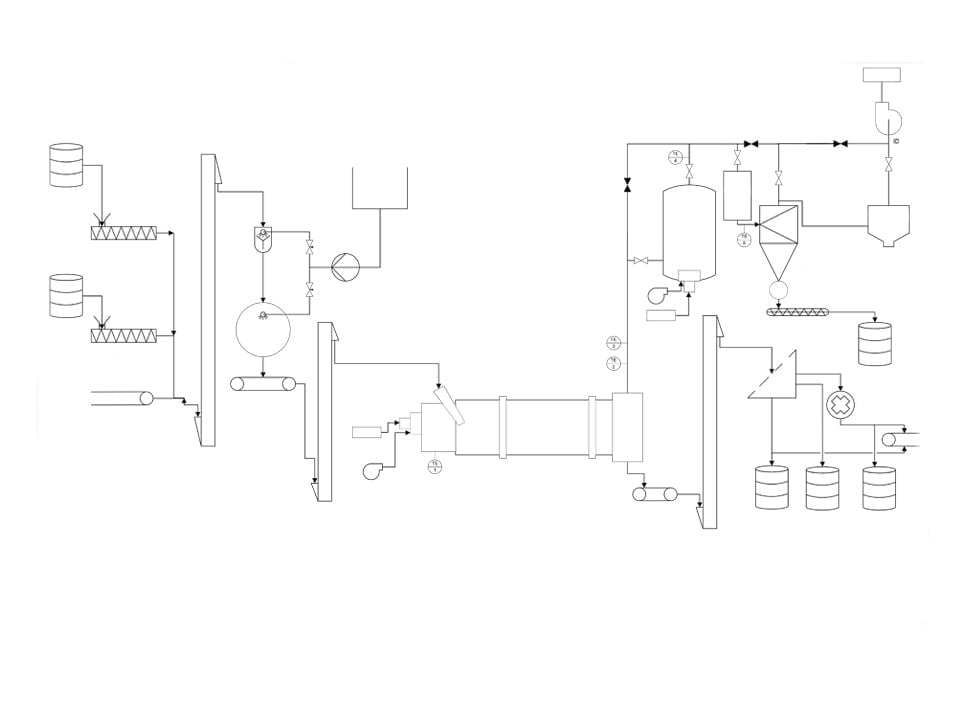

Proof of Process: Agglomeration

In an agglomeration process, the process may also include:

- Feeding equipment

- A rotary dryer

- Conveyors for moving material between each step

- Air processing equipment (such as a baghouse for collecting particulate matter from the dryer)

- Screening equipment

- Grinding/Crushing equipment (such as a hammer mill)

Proof of Process: Thermal

In the case of a thermal process, supporting equipment might include:

- A baghouse for particulate matter

- Removable flights, dams, or bed disturbers

- Thermal oxidizer

- Wet scrubber

- Water quench tower

Key Takeaway

Proof of process shows that the intended process is viable on a continuous scale. This step also works to establish the parameters necessary to reliably and consistently produce the desired output and quality of product at a continuous rate.

Process/Product Optimization

After confirming that the process is viable on a continuous basis, the final stage of process development can begin: optimization.

How Process/Product Optimization is Carried Out

The process/product optimization stage looks similar to proof of process testing, but instead of proving viability, focuses on fine-tuning the parameters of the process for optimal efficiency and product quality.

Process/Product Optimization: Agglomeration

In agglomeration processing, factors such as binder, raw material, recycle feed rates, disc speed and angle (in the case of a disc pelletizer), retention times, and other data points are refined to create a stable, efficient, and consistent process.

Process/Product Optimization: Thermal

In thermal testing, residence times, exhaust gas composition and quantity, energy/fuel requirements, and more, are fine-tuned to maximize process efficiency and ensure the end product can reliably be produced to spec.

Key Takeaway

Process/Product optimization is the final piece of the puzzle in process development. This stage refines process parameters for optimal efficiency and consistency.

RESOURCES

Process Development ARTICLES

Choosing A Binder in the Agglomeration Process

Choosing a binder is one of the most important aspects of the agitation agglomeration (wet granulation) process. With implications on both …

From Batch Rotary Kiln Testing to Detailed Kiln Design

Since 1951, FEECO International has built a reputation as the leader in rotary kiln design and manufacturing. Part of our success …