Equipment

With more than 75 years of experience processing materials such as alumina, zeolites, silica, and more, FEECO brings producers an extensive range of equipment for various aspects of the catalyst manufacturing process. All FEECO equipment is designed around process and product goals to ensure the equipment meets the exacting specifications of the catalyst industry.

Wet Granulation/Pelletizing (Support Formation)

As a globally trusted leader in wet granulation, FEECO offers the industry’s most reputable pelletizing equipment and systems. Our pin mixers and disc pelletizers are ideal for micropelletizing and converting fines into spherical granules, whether you’re working with an active catalyst component or a catalyst support material.

Our granulation drums offer an alternative option for especially high-capacity settings.

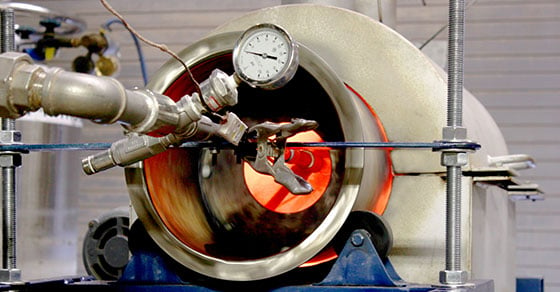

Impregnation & Coating

Achieve uniform impregnation or coating with our custom rotary impregnators, each backed by extensive test work in our process development facility.

Drying

FEECO rotary dryers ensure uniform drying with minimal attrition, whether conducted as part of the catalyst shaping process or after impregnation. These dryers offer extensive opportunity for customization to ensure all product goals, including mechanical strength and bulk density, are consistently met.

Our fluid bed dryers are an alternative for lower-capacity operations.

Calcination

Our custom rotary kilns are expertly engineered to meet your precise calcination requirements. While historically rotary kiln manufacturers have relied on low kiln loadings, FEECO is able to increase kiln loading to optimize kiln size, making the calcination step more efficient and reducing the capital cost of the kiln.

Bulk Material Handling

We offer a comprehensive line of bulk material handling equipment to support catalyst manufacturing plants. This includes custom trough belt conveyors, bucket elevators, reversing shuttle conveyors, steep incline conveyors, belt feeders, and belt trippers and plows.

Plant and Pilot Scale Process Testing and Design

The FEECO Innovation Center gives producers a unique opportunity to test several aspects of the catalyst manufacturing process, from pelletizing and impregnation, to drying and calcination.

With a variety of batch- and pilot-scale equipment available, we can offer comprehensive testing in several categories:

Feasibility/Proof of Concept: An initial, non-witnessed batch testing phase in which the possibility of creating a product is explored.

Proof of Product: A more in-depth batch testing phase in which more time is spent determining whether a product can be made to desired specifications.

Proof of Process: A continuous testing phase that aims to establish the equipment setup and parameters required for continuous production of your specific material.

Process/Product Optimization: An in-depth study to optimize your specific material’s characteristics and/or production parameters in an industrial setting.

Learn more about the Innovation Center >>

Parts & Service

FEECO provides an extensive line of parts and service to keep your equipment running its best for years to come. This includes dryer and kiln maintenance, as well as a variety of field services, process and equipment audits, spare parts, and more.RESOURCES

CATALYST ARTICLES

R&D Around Catalyst Manufacturing Sees Growth

As the role of catalysts in industry continues to grow, catalyst manufacturing research and development continues to rise. In this effort, …

Rotary Drums for Incipient Wetness Impregnation of Catalysts

Rotary drums have long been a cornerstone in catalyst manufacturing, particularly for incipient wetness impregnation—a critical step in catalyst preparation. FEECO …