Trunnion bearing assemblies are critical to the rotary drum base, providing support to the trunnion wheels, and thereby the drum, as well as facilitating rotation of the unit.

AVAILABLE TRUNNION BEARINGS

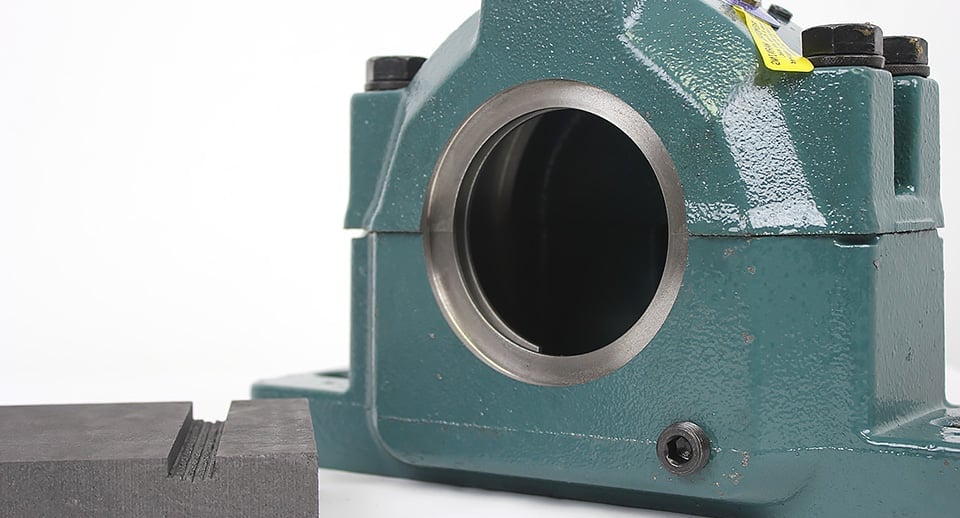

FEECO offers heavy-duty pillow block bearings made of hardened steel with cast steel housing (open or closed) for rotary drums of all types, including dryers, coolers, and kilns. These bearings are engineered for slow-moving, high-torque applications to accommodate the heavy loads associated with rotary equipment and help to ensure a long service life.

With proper lubrication and maintenance, a typical bearing can last reliably for several years.

FEECO can supply individual trunnion bearings as well as complete assemblies incorporating the bearing, housing, and shaft-attachment device (such as a taper or set screw).

Why Bearings Fail

Trunnion bearing failure is rare, but it can happen; bearings that have not been properly lubricated and maintained are particularly susceptible. Bearing seal failures can promote foreign material ingress and may also cause failure.

Addressing Trunnion Bearing Failure

Unfortunately, repair of the bearing is typically not an option and replacement is almost always required.

When a trunnion bearing fails, production must be shut down until the bearing can be replaced to avoid locking up the entire trunnion assembly, making this a wear-critical component. As such, replacing worn or old bearings preemptively is critical to preventing unnecessary downtime and lost production.

With a lead time ranging anywhere from four to 30 weeks depending on size, FEECO recommends keeping replacement trunnion bearing assemblies on site for a quick change out in the event of a failure. Further, since bearings experience similar wear conditions, keeping a minimum of two on-hand is advisable; if one bearing fails, it is not unusual for another bearing to shortly follow suit.

INDICATIONS THAT A TRUNNION BEARING MAY REQUIRE REPLACEMENT

A worn or failed bearing can present itself in a number of ways. This might include excessive heat or vibration around the bearing, loud noises, inconsistent or lurching movement, or in the case of failure, a seized shaft. In some cases, grease on the outside of the unit may indicate trouble as well.

FEECO recommends routine inspections of the trunnion and bearing assembly as part of a preventative maintenance program.

The Replacement Process

While FEECO offers standalone bearings, it is typically more cost-effective to replace the entire assembly, because the bearing is a major portion of the cost. Replacing the entire assembly also avoids the risk of contamination that could result from opening the housing to replace only the bearing.

With a replacement bearing assembly on site, the change out is simply a matter of removing the old and installing the new. This requires removing the trunnion wheel and bearing housing, removing the bearing itself (typically mounted with a tapered sleeve and lock nut), and then replacing the bearing and reinstalling the bearing housing and trunnion wheel.

In addition to supplying bearings, FEECO Customer Service Engineers can visit your site to perform the bearing assembly replacement and ensure it is carried out properly.

Tips for Maximizing the Service Life of a Trunnion Bearing Assembly

As an essential component to the drum’s support system, plant managers should prioritize maximizing the service life of the bearings in their care. FEECO recommends the following guidance to properly maintain bearings:

- Follow manufacturer guidelines for proper lubrication type and frequency.

- Regularly monitor bearings for vibration and temperature. Ensure operators and maintenance personnel are adequately trained to recognize potential problems.

- Never “open” bearing housings unless there is a specific need to do so, as this can risk contamination.

- Routinely inspect seals, mounting hardware, and cap bolts for signs of wear or failure. Replace as needed.

- Prevent buildup from accumulating around the bearings. If necessary, regularly clean out trunnion pits, as fugitive material ingress could degrade the bearing and shorten its service life.

Contact our Customer Service Team for a quote on a replacement bearing or other rotary drum parts.