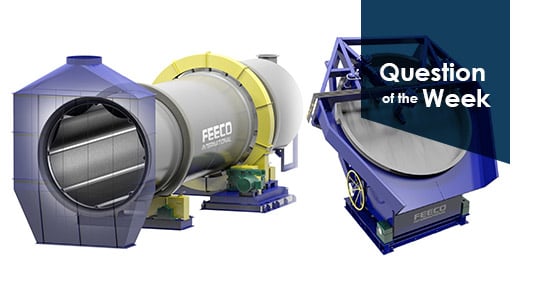

During the pursuit of an effective non-pressure agglomeration solution, the choice between a rotary drum and a disc pelletizer (also known as a pan granulator) often arises. To help determine the best equipment for your material and process, the following should be taken into consideration: recycle, throughput, and maintenance.

Recycle. One item to consider is recycle, or the amount of material that is not on-size and must be put back into the beginning of the process. Overall, a disc pelletizer generates less recycle than its drum counterpart. This is ideal when a material goes from a pelletizer to a dryer because the less recycle that has to be dried, the more efficient the process will be (i.e. the more recycle to be dried, the more energy consumed to dry it). It is also important to note that a high amount of recycle could also be beneficial to a rotary drum process. When operating a drum, the higher amount of recycle can act as a buffer if there is an upset in processing; there could be enough recycle in the process to even things out. With a disc pelletizer, however, there is little recycle and therefore the output is almost immediately affected if there is an upset in conditions.

Throughput. Rotary drums are the ideal equipment of choice for high capacity applications and can handle a higher throughput than disc pelletizers.

Maintenance. Disc pelletizers generally require less maintenance than rotary drums, and have fewer parts that need replacing.

For more in-depth information on agglomeration equipment, download our handbook, or contact a FEECO expert today!