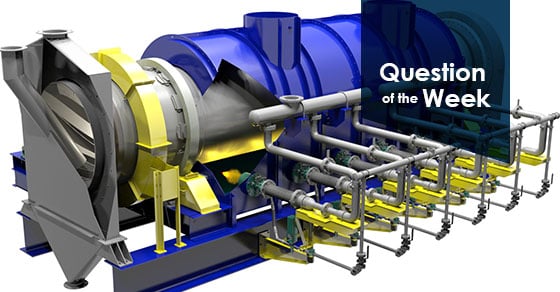

To process biomass into biocoal, residuals from the forest products industry are first dried in a rotary dryer to reduce the moisture content and improve combustion. Next, the dried biomass is processed in the oxygen-free environment of an indirect rotary kiln to remove volatile components.

Biocoal is the resulting product. Oftentimes, it is then pelleted via extrusion to produce a product that is easy to handle and implement alongside traditional coal products.

The transformation of biomass into biocoal works to maximize and concentrate the heating value of the product, and to also improve combustion. Biocoal is easier and less costly to handle and transport than raw biomass, and it allows facilities to operate at the same capacity without derating.

To learn more, read our post Biocoal: The Key to Turning the Coal Industry Around, or contact a FEECO expert today!