The process of converting biomass to activated carbon can vary depending on the source and characteristics of the feedstock material, and the wanted end-product characteristics. This process is outlined in the stages below:

Drying. Biomass must first be dried, most often via a rotary dryer, before it can be used in any application or upgraded. Once dried, biomass can then move on to conversion to a higher value product, or it can be used as a fuel source.

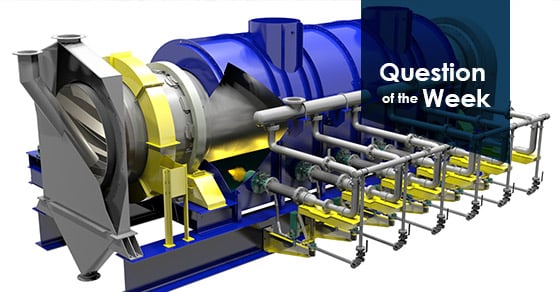

Devolatilization/Carbonization. Devolatilization or carbonization is the process of removing volatile components from the material. It occurs after drying, at around 1000 – 1200°F and is often accomplished through use of a rotary kiln.

Activation. After the material has been devolatilized, activation can take place. This is most often achieved by injecting steam into the process which activates the material by clearing out the porous structure and leaving a material ready for use as an absorbent. Rotary kilns are also used for the activation step.

For additional, in-depth information, view our blog post The Thermal Conversion of Biomass to Activated Carbon (And Everything in Between), or contact us today!