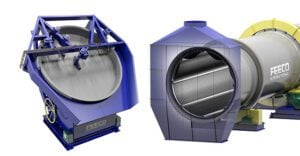

Photo of the Week: Coating Drum in Operation

This photo of the week shows the inside of a coating drum while in operation at the FEECO Innovation Center. Coating pellets is desirable for many reasons, including to control dust, caking, or moisture absorption, or to improve flowability of a material. Coatings are also …