There are three generalized and accepted approaches for the granulation of organic waste and manure streams.

The first is a mixer to drum dryer granulation approach, with the mixer being either a pin mixer, or paddle mixer. In this approach, mixer selection is based on the feedstock analysis. Typically, a high speed pin mixer is used for more dry, finely divided feed, such as a chicken litter or compost. A pugmill mixer or paddle mixer is generally used when the feedstock is a sludge, paste or slurry, or in the case of things like filter cakes and dewatered liquid manures.

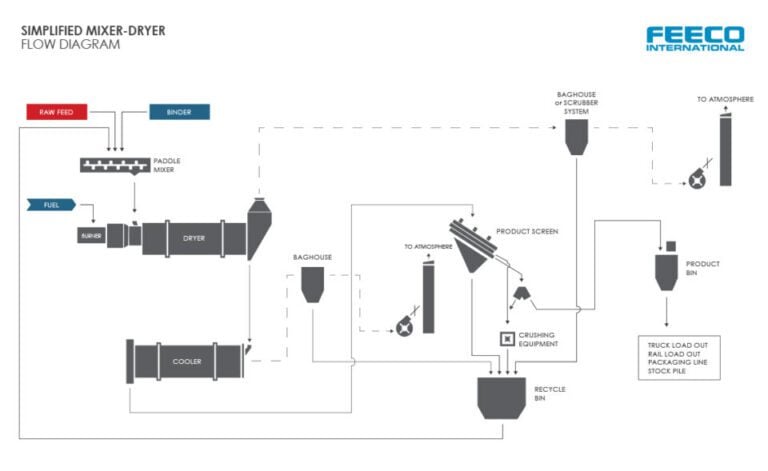

Mixer-Dryer Organics Granulation System

The image below shows a simplified organics granulation system with a mixer-dryer setup. Click image to view larger.

| Flow Diagram Key | |

| A – Raw FeedB – Binder (Optional)

C – Paddle Mixer D – Fuel E – Burner F – Rotary Drum Dryer G – Dryer Cyclone H – Product Cooling System I – Screen Feed Hopper |

J – Product ScreenK – Product Diverter

L – Crushing Equipment M – Recycle Bin N – Baghouse O – Gas Cleaning System (Optional) P – Stack (to Atmosphere) Q – Product Bin R – Load Out, Packaging Line, Stock Pile |

Pin mixers are often used as a pre-conditioning unit, or as a stand-alone agglomerator. Pin mixers accept multiple solid and liquid feeds. The relatively high speed creates a turbulent mixing of the material, resulting in a very thorough mix of liquid (binder), raw feed, and recycle.

There are many advantages to this type of approach. This approach reduces the amount of liquid required for agglomeration, and allows high liquid levels without over-wetting. It also reduces the chance of selective agglomeration, and also the chance of segregation due to density differences in feedstocks. In addition, pellets made in this process have improved crush strength, and less attrition. The mixer to dryer approach is also advantageous because it is a simple, closed system. Odor is minimized, control is easy, and it does not require a lot of special knowledge or skill. Things like speed, pin/paddle arrangement – all can be adjusted to vary the size of the desired pellet.

Though there are many advantages to the mixer to dryer granulation method, there are also a few disadvantages. Oftentimes, a tight moisture window in the pin mixer can limit control. Pin mixers also require a finely divided feedstock, meaning the addition of pre-processing equipment such as pre-grinders or de-lumpers may be a necessity. Also, when dealing with sticky or wet feed, material handling can pose a challenge.

The next approach, similar to the first, is simply the addition of a pan pelletizer to the process, after the mixer, and before the dryer. Adding a disc pelletizer to the process adds an element of fine-tuning and control over the end product. Things like spray locations, scrapers, incline, and speed, are all methods of optimization with a pan pelletizer, and help offer more control. In general, adding a pan pelletizer to the process basically improves efficiency and quality of the end product. Not only does a pan pelletizer create more on-size product, but the product is a little more dense, and has a more round shape to it, as opposed to solely a mixer, where the end product is a little rougher, and more oblong. Pans are also flexible with the addition of binders.

Mixer-Pelletizer-Dryer Organics Granulation System

The image below shows a simplified organics granulation system with a disc pelletizer. Click image to view larger.

| Flow Diagram Key | |

| A – Raw FeedB – Binder

C – Pin Mixer D – Disc Pelletizer E – Fuel F – Burner G – Rotary Drum Dryer H – Rotary Cooler I – Baghouse J – Stack (to Atmosphere) |

K – Product ScreenL – Product Diverter

M – Crushing Equipment N – Recycle Bin O – Baghouse P – Stack (to Atmosphere) Q – Product Bin R – Load Out, Packaging Line, Stock Pile |

The disadvantage to adding a disc pelletizer to the process is that it then becomes an “open” system. This results in more housekeeping due to dust and particles, etc. Also, an open system can be much more odorous than a closed one. Probably the biggest disadvantage for most, is that the addition of a pan pelletizer makes the process more labor intensive. Using a pelletizer has been compared to an art by some, requiring a bit more specialized skill and knowledge than a simple mixer to dryer granulation system.

The last approach is the extrusion method, whereby a dry pellet mill and crumbler are utilized. We will not focus much on this method, as we primarily work in tumble growth agglomeration. Extrusion, a pressure agglomeration technique, uses compaction to force fine materials through a mold, melding them together to create a pellet. This creates a pellet in the shape of a cylinder. There are advantages and disadvantages to this method.

No matter what the method of granulation, typically, traditional fertilizer processing equipment and designs can be customized and designed to produce “market-ready” bio-based fertilizer products.

Next we will look at the things to take into consideration when looking at an organics granulation system.